Clamps for fastening pvc pipes and other methods of

In the process of installation of plastic pipe systems, not only the quality of the material itself is very important, but also the correct selection of fasteners, which ensures efficient and reliable operation of the created pipeline. This article will consider various methods of fasteners and installation of highways made of PVC pipes, for the implementation of which can be used clips and clamps for fastening pipes according to GOST 24137 80.

Types of fasteners for products from polyvinyl chloride

The process of fixing the pipeline during installation will not require the purchase of specialized equipment.

In order to produce reliable and high-quality fixing of PVC materials when laying the pipeline route, holders for pipes of the following type are used:

- Plastic clips;

- Mounting clamp.

Mounting step

Do-it-yourself installation of fixing elements requires compliance with some rules in order to ensure efficient and long-term operation of the pipeline. In order to avoid the occurrence of deflections of the line, it is necessary to strictly maintain the recommended distance between fasteners. (See also the article Clutches for pipes: features.)

Technical rules and regulations stipulate that the clips and clamps for fastening pipes should be located as follows:

- Installation interval for small diameter pipes (not more than 20 mm):

- Cold environment of operation of the system - 80 cm;

- Highway hot water (over 60 degrees) - 65 cm;

- To install a pipeline with a diameter of 40 mm, the pitch between fasteners should be 95 cm for hot water supply and 110 for cold water;

- Highways with a large diameter of 110 mm or more in diameter are fixed by elements located 185 cm apart for transporting cold liquid and 160 cm for moving hot water.

Clip Mounting

Plumbing clips for PVC pipes are manufactured using nylon technology.

It is this kind of additive that allows the product to impart important performance characteristics, such as:

- Increased thermal stability coefficient;

- High strength, withstand the effects of mechanical type;

- Ease and simplicity of installation;

- Low price.

Products such as clips are available on the market in a huge range of sizes, so that you can choose the most suitable for fixing pipes of various diameters. In order to produce a reliable fixation of this type of elements are selected, so that the inner diameter exactly matches the outer diameter of the pipe.

The holders for the clip-shaped mains provide them with axial movement during the expansion process when the temperature rises. It is for this reason that they are most often used when creating a system for transporting hot water or for heating systems.

Council If you need to lay several branches of the pipeline close to each other for fixing to the wall, for example, you can use double clips.

Using hose clamps

If the communication system is created from materials of large diameters for transporting masses with a serious weight, then it is more expedient to use not plastic clips, but clamps. Structurally, such a product is a conventional screw-type tie, inside which is a carefully laid rubber gasket.

This type of element will allow to compensate for the vibration of the system in the process of transporting large volumes of medium. It is because in the process of serious and significant fluctuations in the network, they allow you to securely hold the position of each of its sections.

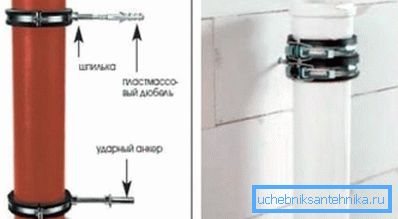

Clamps for fastening PVC pipes are completed with dowels and specialized stud. In the market you will find both plastic and steel pipe clamp.

In spite of the fact that fastening with the help of such elements is considered to be rather rigid, making efforts in the process of fixing the system, you can get the following results:

- Rigid fixation of the pipeline, achievable only with maximum tightening of all bolts. This property allows you to use fasteners to fasten a portion of the system to minimize displacement;

- Floating mount for PVC products. If the fasteners are not tightened enough, then there will be a small gap, allowing the pipeline free movement. This type of installation may be required in case of temperature fluctuations in the working environment.

The main types of clamps

There are clamps of the following form:

- Cable ties. Such fairly simple products are also called clamps. Manufacturers supply them with fasteners located on the inside. They are used to fasten and fix cables to different surfaces, both vertical and horizontal. Such screeds are made of polyamide, which is a durable polymer;

- Pipe Clamps. The weight of the clamp for fastening pipes is the biggest, because make them from steel. They consist of two parts that are bolted together. Reliability and tightness of the mounting provides a rubber gasket on the inside of the product, but there are options without it;

- Construction fasteners for fixing pipes are used to create scaffolding. They have an enviable strength and allow not only to connect the details of the forest, but also to attach them to the bearing surfaces;

- Belt or worm used to connect pipes and hoses, as well as for attachment to walls and ceilings.

Note! Worm clamps besides fixing function allow to keep tightness of hoses.

In addition to classification by type, such fasteners are classified depending on the material from which they are made:

- Metallic;

- Plastic.

The order of fasteners with clamps

Using such products as a clamp for fastening pipes 110 or of a different size during the installation process, it is possible to carry out all the work on pipe laying fairly quickly.

To do this, the following step-by-step instruction should be executed:

- To begin with, the entire road must be marked.

Council At this stage, you must not forget that the sewer system is placed at an angle. If you are busy installing the water supply system in unheated rooms, you also need to install under a slope in order to avoid stagnation and accumulation of water.

- At the place of installation of the route, it is necessary to mark the locations of the fasteners, taking into account the allowable distances between them;

- Drilling holes in the installation locations for the dowel;

- With the help of a hammer and a screwdriver, you must mount the clamps in places that were previously marked and drilled;

- At the final stage, we insert the pipes into the clamps and tighten the fastening to the required level.

Finally

Using products such as clips and clamps, you will be able to independently and sufficiently quickly install the pipeline without using a specialized tool and without special skills.

Well, the pipes, fixed in this way, will perform all the functions assigned to them for a long time without any problems. The video in this article will tell even more information about how to produce PVC fasteners.