Copper pipe soldering equipment: disassemble features

For over 100 years, communications from copper have been in steady demand. Some choose them as an indicator of prosperity, others are attracted by enviable durability, but be that as it may, copper pipes in any sphere are distinguished by high performance and ease of installation with their own hands.

Despite the fact that this material cannot be called a budget decision, rumors that the cost of arranging plumbing or heating from copper is fabulously high is greatly exaggerated.

Pipes really cost money, but fittings and other connections are much cheaper for them than quality polypropylene products. Plus tool for soldering copper pipes has an affordable price.

What you need for soldering

Perhaps the main actor for the permanent connection of such products is a gas burner for brazing copper pipes.

But we will tell about it in detail a bit later, and now we will talk about auxiliary and not less necessary adaptations.

- For precise pipe cutting, professionals use a specialized pipe cutting tool.. It is equipped with a cutter of high-strength material that provides a high-quality cut. The price of the device depends on the diameter of the products with which it can work. At home, you can use a hacksaw for metal, it is convenient to cut it, but the cut will not be quite even.

- The next important tool can be considered a phasmodus. It is necessary for chamfering, that is burrs and irregularities from the edge of the cut pipe. Without this device, joining the elements will be quite problematic, plus chips can get inside the system. You can use the file, but it is long and troublesome.

Important: 2 types of products are produced, the round face picker is more convenient, but it is designed only for diameter up to 36 mm. A pencil type pick-up can work with any section, but you need to have a certain skill to use it.

- The pipe expander is a very convenient device. The fact is that the material for arranging the wiring, as a rule, is taken of the same section and in order to connect 2 identical pipes, use a transition sleeve. In the presence of a pipe expander, one of the two connected ends of the line can be slightly moved apart and made a reliable connection without the use of additional fittings.

Important: the pipe expander is brought into the pipe to a depth of at least 1 diameter. Thus, you can push the walls of the soft alloy, if the walls are thick or copper alloy is sufficiently elastic, then the edge of the product must be burned.

Manual compact gas burner

As previously mentioned, the main working tool is a gas burner for brazing copper pipes. The range here is quite wide, for amateur use, on small volumes a small disposable propane torch is used for soldering copper pipes.

There are semi-professional models and finally, at large construction sites, professionals use a mobile apparatus for soldering copper pipes.

The appearance on the market of hand-held burners mounted on a small gas cylinder has opened up broad prospects for building the system with your own hands. The compactness of the product determines the convenience of working in hard-to-reach places, such as bathrooms or kitchens.

Such burners can be refilled with different gas mixtures, with different temperatures of combustion. It all depends on the type of solder and on what alloys will be mounted.

On the holder there is a special valve with the help of which the length and focus of the flame are adjustable. Plus, this set is equipped with several removable nozzles, as a result, it is possible to control the heating rate of the material.

Work safety is ensured by a built-in check valve. Manual torches are completely autonomous tool, they do not need additional feeding elements. With their help, with certain skills, you can make highly professional seams.

Models equipped with a flame reflector are produced, which provides gas savings and uniform surface heating.

Professional equipment

A professional apparatus for soldering copper pipes, like most specialized equipment, is more cumbersome. If a gas-air mixture is used for heating in an autonomous manual spray, the professionals often solder the gas-oxygen mixture. The burning temperature here is much higher, as a result a torch can be used to solder copper pipes with hard solder.

The whole installation is based on a small mobile carriage and consists of 2 gas cylinders with propane butane and oxygen. In some cases, acetylene may be used instead of propane-butane. Oxygen, on the other hand, performs the function of an active oxidizing agent, while gas is supplied to a professional burner through special gas hoses.

Important: in some cases, for soldering with fusible materials, it is allowed to use a specialized electric soldering iron as a heater.

Soldering compositions

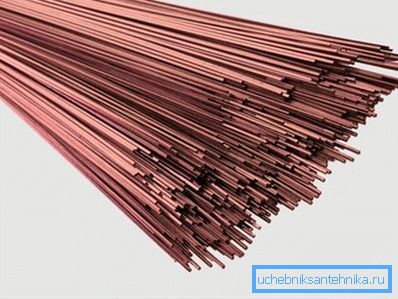

For good joining, solder is also required for soldering copper pipes with an optimal heating temperature. Visually, it looks like an ordinary wire with a cross section of 2 - 6 mm.

Its melting point is slightly lower than that of a copper pipe. Due to the capillary effect, when it melts, it flows between the pipes, forming a rigid, tight, durable seam.

Solders are hard and soft.

- For the installation of heating systems are often used ordinary soft tin solder. It refers to low-melting and is able to provide a reliable connection at temperatures up to +180? C.

Important: tin-based solder contains a certain percentage of lead. For this reason, it is prohibited for use in systems that transport drinking water.

- Air conditioning systems and pipes in low-temperature freezing chambers are connected using solid copper-phosphorus solder, in which there are inclusions of silver. When soldering a pure copper pipeline copper-phosphor solder does not require additional use of flux. If the pipe contains more than 10% nickel or you need to solder aluminum bronze, then the copper-phosphorus composition will not work.

- In such cases, silver compounds are used, the higher the percentage of silver, the better the soldering will be. For example, a compound containing up to 35% silver is necessary for combining with iron.

- Flux for soldering copper pipes is used in the case of connection with other metals, brass, bronze or iron. It provides better adhesion of the surface of the material and prevents the formation of oxides. It comes in a different consistency, both in the form of liquids and in the form of gels. Apply with a brush and after work wipe with a wet sponge or rinse with water.

- Now widely used paste for soldering copper pipes, it can be called an improved flux. Depending on the purpose, the paste contains powdered solder powder, a binder and a flux to improve adhesion. The application of such a solution to the surface provides fast and high-quality adhesion. These pastes do not contain lead, so they can be used everywhere.

A few words about the soldering technique

Any welded work requires material preparation. Regardless of whether flux, paste or work will be performed without these compounds, the surface of the pipe, in any case, should be cleaned. To do this, use a brush for metal or a special sponge.

Tip: Experts do not recommend cleaning the surface with sandpaper or other abrasive materials. Since abrasive particles can significantly reduce the quality of the connection.

For domestic heating systems or water supply, you can do without the use of fittings, but for the connection you will need a pipe expander. The expansion is done in such a way that the gap between the walls of the pipes to be joined is in the range of 0.025 - 0.125 mm.

Next, proceed to warming up the connection. The instruction requires that heating be uniform. It is not necessary to bring the metal to the melting point; this can later lead to a defect in work or decrease in the characteristics of the compound.

In order for the solder to be distributed evenly over the entire area of contact, it is necessary that it melts from the touch of the heated metal. It is not necessary to heat the solder itself with a torch, because if the metal is not sufficiently heated, a good-quality connection will fail. The product cools, usually within an hour.

The video in this article shows the subtleties of soldering.

Conclusion

Years of experience in the joining of copper products shows that for beginners the most difficult is the choice of solder and related materials. The process of soldering is easy to master, the tool for soldering copper pipes is inexpensive and under the guidance of a mentor all science can be comprehended in a day (see also the article Polypropylene pipes and fittings: features, standards, installation tips).