How to make a machine for bending a profile pipe with your

Profile pipes are a widespread material that is used to create furniture, manufacture various metal structures, decorate the interior, etc. Their feature is high bending strength, which is good on the one hand, but on the other, it greatly complicates the bending process to produce a curved part. However, this problem can be solved with the help of a special machine.

If you often have to deal with shaped pipes, then such a mechanism must necessarily acquire. In this article we will look at how to make a bending machine for a profile pipe with your own hands, since the cost of the finished equipment is very high.

Machine making

The foundation

At first glance it may seem that to make a device similar to branded bending machines for a profile pipe is very difficult. However, a person who knows how to handle metal and a welding machine is quite capable. The main thing - to approach the work slowly and in stages.

It should begin with the manufacture of a solid base - a metal table. You can run it from a metal profile or other material. The most important thing is that it is stable and durable; otherwise, even a well-executed mechanism will be useless.

Manufacturing mechanism

Once the table is ready, you can proceed to the manufacture of the mechanism itself. To do this, first of all, prepare three shafts that will be used to bend the part. The shafts are thick metal rollers, necessarily having an axis for rotation.

They can be ordered in the workshop or search for sale on the "flea markets". When this parts are ready, you should make a case for the mechanism and complete the assembly.

The instruction is as follows:

- First of all, it is necessary to cut a housing for a device from a sheet of metal with a minimum thickness of 5 mm, which consists of two trapezoids, between which are shafts.

- Then in the resulting trapezoid holes must be made for the axes of the rollers. Two shaft should be located above the table, and the third above them, at an equidistant distance from them.

- It should be borne in mind that the distance between the two lower shafts determines the bend radius. To make a homemade bending machine for a profile pipe was universal, the design can be complicated and the radius can be adjusted, for this you just need to make several seats for the rollers, which will allow you to change the distance between them. The location of the upper roller determines the maximum diameter of pipes with which you can work. Its position can also be made adjustable with a threaded rod, which allows the shaft to move along the guides and at the same time be securely fixed.

- Next, you need to fix the details of the case on the workbench. This can be done by welding or bolting. In the second case, it is necessary to provide bent ears with holes from below. The distance between the body parts should correspond to the width of the shafts.

- After fixing the case on the base, you need to install the remaining parts.

- When the shafts are installed, care should be taken to transfer the torque to them.. The best option is a chain mechanism. For this you need to purchase a chain with three gears.

Two gears should be installed on the lower shafts. The third will serve as a tensioner, which is located below between the two upper gears.

- Then to one of the shafts need to attach a handle for rotation.

Now the machine for bending the profile pipe is ready. It remains only to get the profile between the upper and lower shafts, and try the product in action.

If at all stages all the work was done without errors, then the functionality of the product and its design will fully comply with the original machine. Of course, despite all the costs that will be needed for the purchase of parts, the cost of such a machine will be disproportionately lower than the price of the finished equipment. (See also the article Pipe benders for pipelines: features.)

Making a simple design

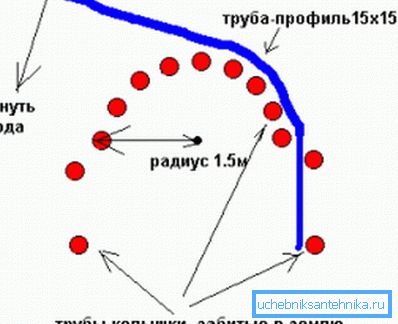

If you do not have the opportunity or time to perform a full-fledged machine according to the scheme described above, then in this case there is a simpler option. For the device of this design will need:

| Concrete slab | Will serve as the basis of the design. |

| 10 metal retainer pins | A tube will be curled around them, so the pins must be strong. |

Tip! If there is no concrete slab, you can pour the concrete base yourself and wait until it hardens.

To perform such a construction is very simple:

- First of all, on the basis of the need to draw a bend radius.

- Then along the bend line you need to make 10 holes at the same distance from each other.

- Further in the holes it is necessary to fix the metal pins (if the base is poured, the pins can be concreted).

- On the two extreme pins, it is necessary to perform a pipe fixing mechanism - this may be near an additional pin, a hook attaching or something else.

So, the design is ready. To bend a profile, you need to fix its end on the outermost pin and slowly bend around the other racks. When the item docks with the last pin, it must be fixed and left in such a form for a while.

Tip! To make it easier to bend the pipe, it must first be heated.

Conclusion

It is quite simple to execute a machine for bending in shaped pipes, having some skills in working with metal. The only thing you have to spend on parts that can not be done independently. If you do not have the need for constant pipe bending, you can perform a simpler design, which will take much less time and money to manufacture, although it will require much more effort to bend the profile.

From the video in this article, you can get more information on this topic.