How to make a pipe bender with your own hands at home

Work on the house or on a country site sometimes requires bending a metal tape, a round or shaped pipe along a certain radius. If this happens infrequently, it makes no sense to purchase factory equipment. In this article we will discuss ways to help make the pipe bender with their own hands in the conditions of cottage or at home.

A bit of theory

The most popular products from metal today are shaped tubes that can be used to create:

- fences;

- garden furniture;

- nets;

- temporary shelters for cars;

- greenhouses;

- laying of water supply networks;

- garages.

The basis of the technology of such structures is the ability to properly bend pipes at the required angle. At the enterprises for this there is a special equipment that allows you to perform the bends of products at angles of 0? -180 ?.

In this case, the work is done through the use of electricity or hydraulics. This allows you to easily bend pipes of different materials with a diameter of up to 50 mm.

Design features of the tool

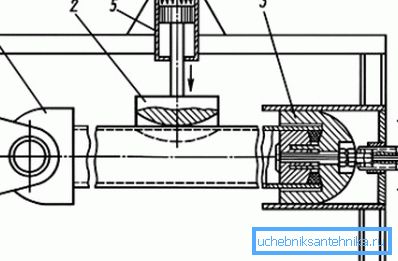

It consists of:

- frames - open or closed;

- hydraulic cylinder - it plays the role of a force mechanism;

- lower and upper bar;

- two pipe stops.

Consider more:

- The manual version should have a pressure device installed on the rear part of the equipment case, a handle and an overflow valve are also installed there.

- Oil is poured through the upper part of the cylinder, where the corresponding plug is located.

- The lower bar of the installation is screwed onto the threaded part on the front part of the bed, then it is pressed against the fixing nut.

- Upper fastened with two screws and a lock.

- During operation, the stem is extended, capable of returning back due to the action of the spring housed in the hydraulic cylinder.

- Both strips of the device are made in the form of a welded structure.

- Holes are made on the transverse plates, which serve to install the stops.

- Below there are threaded holes for adjusting bolts, adjustable in height.

- The focus of the machine is an element in the form of a pin, it is installed in the holes on the slats. In the middle there is a “stream” that serves as a stop for a bent pipe.

- Bending segments are made from precision steel casting.

- The drive for manual equipment is mechanical and hydraulic, power tools are electric.

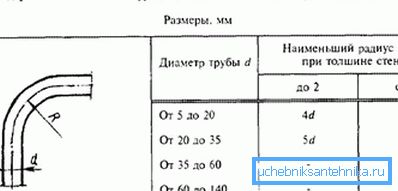

The profile pipes, thanks to their design, have a thin wall, which makes it possible to save metal. The cross section of it can be rectangular, in the form of a square or oval, therefore, if you make the pipe bender’s drawings for the profile pipe with your own hands, you should remember that they differ somewhat from the standard ones.

In this case, the rollers should be selected on the basis of the profile of the intended pipe, which must be bent so as not to deform its cross section.

We do the pipe bender independently

From wood

Such a pipe bender for a round pipe is one of the simplest with your own hands, since you will not need any special details for it, for example, a hydraulic cylinder. It will be necessary to make half of a circle of wood, the radius of which corresponds to your pattern.

| Making fixtures |

|

| Work process | To work with a device that can bend metal, you need the following:

|

Tip: make sure the pipe is quietly placed between the stop and the template.

This option has shown itself well in working with pipes made of aluminum and steel. It will not be difficult to make a template, and there will be practically no financial expenses for it.

Tip: for different pipe diameters, make a different fixture.

From metal hooks

Below is another option that allows you to make a homemade pipe bending structure without much difficulty and financial costs:

- Prepare high strength metal hooks.

- Install them on a solid base at a distance of up to 50 mm from each other, but this directly depends on the diameter of the product you want to bend.

- You should have a semicircle.

- At one end of it, make your palm comfortable.

The method can be considered universal, since it allows you to work with different diameters, and the price of the device is low. To do this, it is enough to reduce or increase the distance between the hooks so that you can work with pipes of different thickness.

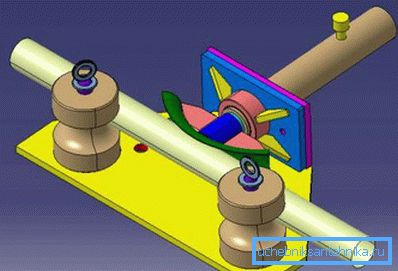

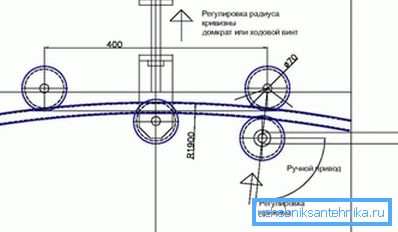

From rollers and cylinder

Now let's consider a more complex structure - making a pipe bender for a profile pipe with your own hands from rollers and a cylinder that is able to bend the workpiece at any angle, even 360 ?. In fact, you will do a manual pipe bender for a shaped pipe with your own hands similar to the hydraulic equipment.

The process takes place thanks to a rotating cylinder and rollers for fixing the workpiece.

The first gives you the opportunity to change the angle of the pipe to your choice, so it needs to be allowed to move freely. Below is a guide to making the design.

You'll need:

- 2 pieces of steel plates up to 300 mm long and 5-10 mm thick.

- 4 pieces of steel corners with shelves 50x50 mm.

- Prepare a wooden template of boards up to 30 mm thick.

- Take a steel plate and secure it to its underside.

- Fasten corners with a length of up to 300 mm on the base of the structure for durability.

- Weld a second steel plate on top.

- Make a hole in it - a drill or welding, with a diameter greater than the diameter of the screw that will be installed in it. The function of the bolt is to serve as a support for the material to be bent.

- Attach the corners and guide rollers to the top plate, orienting them to the inside of the structure.

The pipe profile bender you have made with your own hands will make it possible to change the angle of any profile product.

Conclusion

In this article, you learned how to make a pipe bender with your own hands for a standard pipe and a profile pipe. It was told about three designs that can be made independently for a small amount of money. The choice of each of them depends, first of all, on the diameter of the workpiece and its quantity; moreover, the availability of raw materials plays a significant role in this.

The video in this article will help you find additional information on this topic.