Iron for pipes - tell about the main nuances

With the advent of new materials there is a need for more advanced equipment to work with them. So, now irons for soldering polypropylene pipes are in great demand. We will describe this product further.

General information

Such a device allows you to quickly make a connection.

However, today there are several types of plastic pipes:

- Polypropylene - can have one or several layers. The technology also allows for reinforcement, increasing strength. Today it is the most popular option.

Interesting: in their durability polypropylene products are not inferior to stainless steel.

- Polyethylene - have the lowest temperature limit. Therefore, they are often used for laying external communications.

- PVC is the least resistant material. The only advantage is the low price. It is also worth noting that using such samples, you can use the so-called "cold welding", that is, gluing with specialized substances.

Therefore, consider the variety before going to the store. So, for example, an iron for polypropylene pipes is not suitable for welding PVC products. It is best to consult with the seller-consultant.

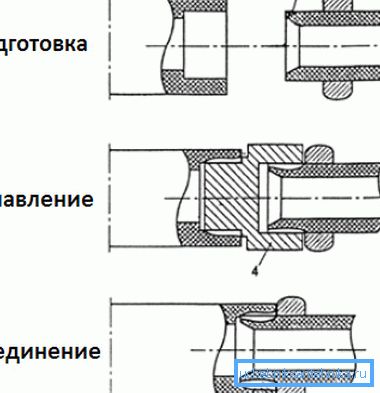

The principle of operation of such devices is as simple as possible:

- The soldering iron is connected to the network (the lion's share of products support 220 V, but more powerful samples may require 380 V).

- Pre-selected connector of a suitable size, which is worn on the heating element.

- Then the element for soldering is inserted into the selected connector.

- Next, the control panel is set to the desired temperature (it depends on the type of compound and material).

- After some time (depending on power), the device will heat the elements and as a result of easy melting, they will be securely fastened.

It is obvious that with such a procedure almost anyone can cope with their own hands.

Tips for choosing

If you have not decided what is the best iron for welding polypropylene pipes, then the information below is for you. The choice of such equipment should be approached with all care, because only in this case, you will achieve the desired result.

Today, in the building stores you can find a huge number of samples, so we have identified for you the main criteria that need special attention.

Optimum power

Perhaps the most important characteristic for this device is power. It determines not only the speed, but also the quality of the connection.

When thinking, use a few recommendations:

- For use in professional conditions, the power must be at least 2 kW. When working continuously with a large number of elements, the instruction requires the presence of such power. Otherwise, you will not cope with the task.

- If the iron is taken for home use, it is better to give preference to samples weaker, because their cost will be several times lower. However, for welding sewer pipes with a diameter of more than 90 mm, the same two kilowatts will be required. For smaller samples, 800–900 kW would be sufficient.

Nozzles

The iron for plastic pipes must be equipped with several welding tips. Of course, if the soldering of products of the same diameter is meant, then they are useless. Otherwise, however, they will be very useful.

Tip: give preference to the nozzles of ordinary teflon, because it has the longest service life.

The most popular samples - with the ability to install just three tips. Such a device will save a lot of time. Especially far in this area went the German manufacturers, who supply a huge number of different devices, allowing to solve even very complex tasks.

Temperature adjustment

Another equally important aspect is the convenience of control. Any high-quality iron for PVC pipes must be equipped with a regulator. Remember that the quality of the future connection will depend on the accuracy of the adjustment.

Professional samples have adjustment accuracy of several degrees. This technique allows you to achieve perfect quality connections. However, for home use such equipment is quite rare, because it has a rather high cost.

Cheaper items should be chosen as carefully as possible. It is advisable to purchase a sample that has an audible alert for reaching the specified temperature. This will allow time to start welding.

Also, experts recommend getting an additional thermometer that will allow you to control the temperature as accurately as possible. Remember that any little things are important, so come to the purchase with the utmost care.

Recommendations for use

If you do not know how to work with an iron for pipes, then the recommendations below are especially for you. Immediately, we note that this procedure does not entail major difficulties, therefore, following all instructions, you will certainly cope with the task.

This procedure is performed as follows:

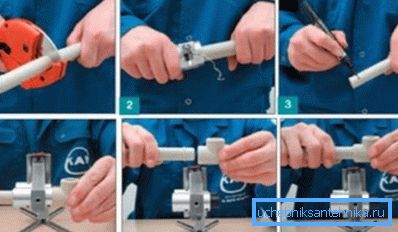

- We prepare the following tools: scissors for cutting, iron for soldering and a set of appropriate nozzles. If we are talking about pipes with reinforcement, then it will be necessary to remove the top layer of foil from them with a special tool - stripping.

Note! Before starting work, make sure that the scissors are sharp enough, because otherwise the connection will not work out quality.

- Next, you need to degrease all the details of any means (for example, you can use such a composition as White spirit).

- Now you need to put on the tube label, matched to the depth of melting with the addition of 2 mm.

- A suitable nozzle should be worn on the welding machine.

- On one side of the heating element a pipe is inserted, on the other element, which needs to be connected.

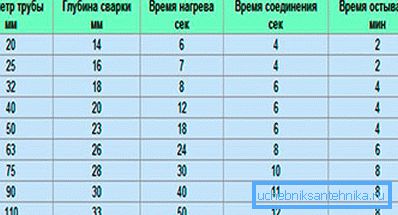

- Having securely fixed the elements, it is necessary to withstand a certain time (depending on the size and material). If we are talking about polypropylene, the soldering temperature should be 260 degrees. At the same time, it is impossible to reach the value of 270, because at this temperature it will begin to seriously deteriorate (its basic technical characteristics deteriorate).

Tip: during operation of the welding machine, make sure that plastic flows do not appear. If they appear, they should be immediately eliminated.

- After soldering, the elements should cool for some time. At the same time, this should occur naturally, and in no case should this process be accelerated by any method.

The result is a very reliable connection, which in all respects benefits metal. Thanks to the countless number of different sewer fittings and accessories, each person can quickly repair the system, and in absolutely any place.

Conclusion

On such an optimistic note, we will complete our story. However, we made sure that you get as much knowledge as possible. In the presented video in this article you will find additional information on this topic, which will allow to understand all the intricacies.