Metal pipe clamps - types and uses

Although the metal clamps are not directly involved in the transportation of liquid or gas through the pipeline, however, they play an important role in the installation of the system. Most often they are used to fix pipes, however, some of their types allow for emergency repair of the pipeline, in case of its depressurization.

Next, we take a closer look at these products, consider their types and features of the application.

General information

As a rule, the clamps are hoops, consisting of two parts, fastened together by means of coupling screws. Metal steel clamps for fastening pipes are also elements for fixing them to different planes.

It may be:

- Plastic dowel with a self-tapping stud;

- Connecting nuts.

Thanks to fasteners, clamps can be attached to a wall, ceiling or floor. As for the repair clamps, they are more, as a rule, wide and do not have fasteners, but otherwise do not differ much from the above.

Regardless of the type of products, their advantages are low price and ease of installation. Typically, installation takes a few minutes.

Note! As a rule, the holders are installed at the joints of the pipeline, which allows to ensure the tightness and durability of the connection.

The main characteristics of the parts are:

- Inner diameter of the part;

- Thickness;

- Width;

- Tightening range.

In addition, products vary in:

- Constructions;

- Purpose

Next, take a closer look at the features of fastening and repair of metal clamps.

Pipe Clamps

Special features

First of all, it must be said that the task of fixing pipes is often not to interfere with the construction of the movement along the axis. This is especially important for heating and hot water pipelines, where thermal expansion can be quite substantial.

At the same time, reliable fastening is of particular importance for socket pipelines, where pipe joints are made using rubber seals. Even a slight deviation from the axis of them can lead to the deformation of the gum and, as a consequence, the depressurization of the pipeline. An example of such systems is free-flow plastic sewage.

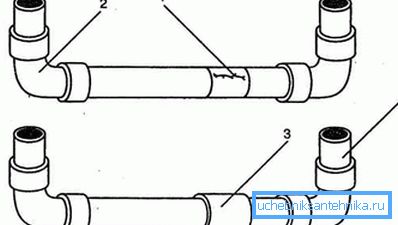

Therefore, there are two types of mounting:

| Movable | This fixture does not allow the pipeline to deviate from the axis, but does not interfere with temperature expansion and shrinkage. |

| Fixed | In this case, the fixed pipeline is not able to move from the point of support. Such fastening is usually used in places of branches and bends of the system. |

Depending on the type of connection, i.e. movable or fixed, the design of the product may be slightly different. For example, a sliding fastener has a rounding inside and can be used without a liner.

However, in any case, the metal clamp for fastening pipes is characterized by high reliability and durability. Moreover, it is suitable for the installation of various types of pipes and any type of pipeline.

Installation

The process of mounting the holders with their own hands is not a big deal. The most important thing is to correctly determine their location, taking into account the fact that they are set vertically at a distance of 2-3 meters from each other, and horizontally at a distance of 1.5 - 2 meters.

When attaching the holders, you must use a rubber seal. Pavda, as mentioned above, when installing sliding hardware seals may not be used.

Tip! If two pipes pass side by side, you can use a double clamp for fixing metal pipes to fix them relative to each other.

The mounting procedure is as follows:

- First of all, on the wall or other plane, near which the pipeline will pass, points of fasteners location are outlined. It is advisable to perform this procedure before installing the pipeline.

- Then, the dowel is installed according to the standard scheme, and the clamp is fastened to it with the help of a self-tapping screw.

- After that, the pipe is inserted into the clamp and the fastener is tightened.

Note! Sliding metal clamps for pipelines should not be too tight, so that they do not interfere with the temperature expansion of pipes.

Pipe Clamps

Design features

When sealing leaks, this product is used as a bandage.

Therefore, its design consists of two elements:

- Crimp material made of steel;

- The inner seal is called a cuff.

Most often, corrugated rubber is used as a seal that seals the damaged area of the pipeline. In addition to sealing, this material performs another function - it prevents the pipe from deforming in case of a strong tightening of the fixing screws.

Bandage installation algorithm

Instructions for eliminating leaks using a hose clamp are as follows:

- At the first sign of depressurization of the system, you need to quickly identify the damaged section of the pipeline.

- Further, in accordance with the size of the damage, the clamp is chosen, which should completely cover it.

- After that, the ears of the product bend down so that they can hold the pipe around them.

- After the bandage is located opposite the damaged area, it is necessary to tighten the bolts until the rubber seal is pressed against the pipe as tightly as possible.

- If the bolts are too long, they need to be cut with a grinder.

This completed the repair of the pipeline. Performing all the above actions will take no more than five minutes. As a result, such a bandage will be able to ensure the tightness of the damaged area for several years.

However, do not forget that this operation refers to emergency and temporary. Therefore, the defective area is still desirable as soon as possible to replace the new pipe or brew.

Conclusion

Metal clamps are the most convenient type of fasteners for household pipelines. Moreover, their proper installation will increase the life of the system and ensure its normal functioning. And in case of emergency situations, the clamp allows you to quickly eliminate the leak (see also the article Oven for a cauldron from a pipe with your own hands: simple and very affordable manufacturing methods).

From the video in this article, you can get more information on this topic.