Pipe bender for profile pipe: design features and

In this article we will talk about how to make a pipe bender for a profile pipe using available materials. In addition, we consider the structural features that unite all the pipe bender drawings for the profile pipe.

But, for a start, we will determine the features of operation of the device.

Application features

It is no secret that the profile metal pipe is a necessary construction material for the installation of such objects as greenhouses, summer houses, canopies, etc.

Of course, it is easy to purchase ready-made used or new metalwork from a curved profile, but the price of such a purchase will be high. You can try to change the configuration of the hollow metal with your own hands. But, it will lead to the deformation of the product, and more precisely to the crushing of its walls.

The solution to this problem will be homemade pipe benders for profile pipe. Why homemade? The reason for choosing a homemade device is obvious - the fact is that a machine correctly made by hand will be an order of magnitude stronger and more durable than the range of inexpensive devices on offer.

The principle of the device is simple: a hollow metal with a rectangular or round cross-sectional shape is laid between the shafts, the position of which varies in accordance with the desired angle of bending. Further, the shafts are driven, due to which the pipe is rolled and bent in the required manner.

A feature of all pipe bending machines is that the mechanical load on the workpiece is distributed gradually and equally at different points, due to which no creasing of the walls occurs.

Pipe bending machine design

Drawings of the manual pipe bender for a profile pipe may differ depending on the type of the device and its design features.

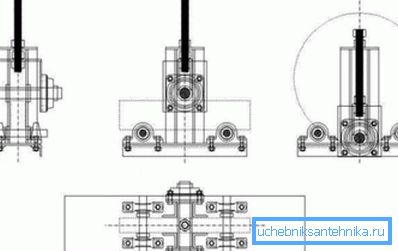

Mandatory elements in the construction of modifications with manual or hydraulic drive are:

- frame (frame) on which all components are mounted;

- lower and upper plank;

- two or more pipe stops;

- shafts;

- hydraulic cylinder or gate equipped with a handle.

The frame on which all components are mounted can be of two types:

- closed type characteristic of factory-made devices;

- open type due to the simplicity of the device, it is typical for most improvised devices.

Important: Instruction manual maintenance of devices with an open frame is an order of magnitude simpler than performing similar operations on a closed frame. But in the second case, operation is safer, since there are practically no open mobile components.

Technological features

Separately, it should be noted form, which is different shafts for pipe benders profile pipe. If, when working with pipes with a circular cross section, shafts with a rounded notch are used, then the rolled sections can be bent using shafts with the appropriate cutout configuration (see also the article Fittings for plastic pipes - an overview of the main options and their features).

However, taking into account the fact that profile rolling during bending does not imply the need for supporting side walls, you can use shafts whose width will be many times larger than the width of the profile, which for obvious reasons is impossible when machining round pipes.

The subtleties of self-production

After we considered the principle of operation and features of the device, it’s time to decide how to make a pipe bending machine for a shaped pipe on your own.

In order to assemble a simple manual pipe bender, the following tools and materials are required:

- welding machine;

- clamps;

- LBM "Bulgarian" with disks for cutting metal;

- square and tape measure;

- cutting steel channel or angle (the size is selected in accordance with the sizes of pipes);

- a large bolt and nut with an appropriate thread (the best solution would be the gate, completely removed from an unnecessary manual press);

- 6 large one-dimensional bearings;

- thick-walled tube with an outer diameter corresponding to the inner diameter of the bearing;

- unnecessary steel connecting rod with an asterisk from the bike;

- additional bicycle sprocket from the rear wheel;

- bicycle chain.

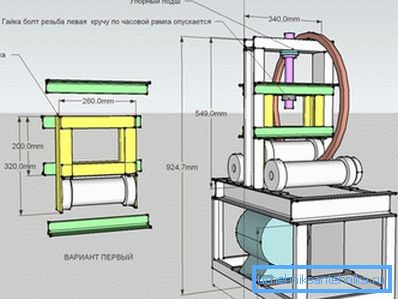

After all the tools and materials are prepared, you can begin to work. As an example, we will use the following drawing of an improvised pipe bender for a shaped pipe.

The assembly instruction is simple and consists of the following steps:

- From the channel we cut the blanks for the manufacture of the horizontal frame and weld them into a solid frame. If there is a solid metal plate of appropriate sizes, it is possible to significantly simplify and speed up the installation.

- Billets for vertical guides are cut from the channel and are welded into a sort of “U” -shaped guillotine. Vertical guides are welded to the frame as shown in the drawing.

- In the next step, bearings are welded to the frame. If there are bearings of this configuration as shown in the drawing, it is possible to use a bolted joint, not welded.

- In the upper crossbar of the vertical guides a hole is drilled under the gate. A pre-centered nut is welded over the hole.

- A tube is inserted into the holes of bearings mounted on the frame, cut off so that an end of 2-3 cm is left at each end. We catch the pipes by welding so that they rotate around their axis but do not go from side to side.

- Next, we assemble from the bearings, scraps of the pipe and channel the upper unit, which along the guides will fall down and exert pressure on the curved pipe. The upper plane of this node is designed to rest against the end of the gate and put pressure on the entire node, moving it to the bed.

- We equip two bearings fixed on one side of the bed with sprockets, which are welded to the ends of the pipes.

- We fasten the bicycle crank with the pedal axis to one of the stars, which will function as a handle.

- Between the asterisks we stretch the chain and the device is ready for operation.

Important: We have not specifically indicated the exact sizes as such installations are made from what is on hand. However, try to ensure that the thickness of the metal used is not less than 2-3 mm.

Conclusion

Now you know how to make a manual pipe bender, which can be applied on the farm. You can find more useful information by watching the video in this article (see also the article Fittings for steel pipes - we analyze all the features).