Pipe bending machine: how to quickly and easily shape the

Often, when installing a new heating or plumbing system or when repairing them, there is a need to bend the pipe at any angle. To take it to the factory to use a stationary machine is too expensive, and it takes a lot of time.

The following describes the technology of bending pipes of various materials in the domestic environment.

Types of manual tube bending equipment

According to the method of operation, portable pipe benders for bending pipes are divided into such types.

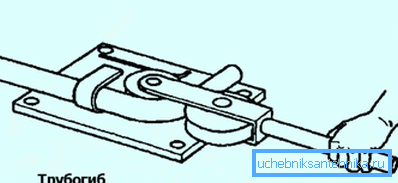

Machine design

- Crossbow analogues. They use a special form (pattern), intended for products with different sections.

- Spring attachments. When using them, a spring is inserted into the product, which helps to bend aluminum, plastic and metal-plastic pipes without distortion.

- Segment Devices. Bending in this case is obtained with the help of removable segments, pulling the product around itself. The machine has a set of templates designed to create different radii.

- Dorn for bending pipes allows you to process thin-walled elements, and make small radii.

By the type of drive produced the following devices.

- Muscular (manual) machines are used for processing pipes with a small section of non-ferrous metals, steel, plastic.

- Hydraulic devices allow to bend products with a diameter up to 70/75 mm.

- Electromechanical counterparts guarantee accurate angles and radii of pipe bending. They are suitable for products of all diameters.

Note! For living conditions optimal hand tools. It bends copper, aluminum, steel, metal-plastic pipes having a diameter of 10 to 25 mm.

How to bend a pipe with a manual device

Below is a method of pipe bending using a segment device.

- Set the desired angle of rotation on the tool.

- Hold it in a vice or take it in your hands.

- Insert the tube into the fixture.

- Begin to reduce its handle to the desired state of the element.

Even more convenient for bending thin pipes in a cold state is the Volnova machine, so named after its inventor.

- Insert your own element between the rollers so that one side of it is in the clamp.

- Using the handle, rotate the strap around the roller. It will not move until the desired fold is obtained.

- Return the handle to its original position.

- Take out the item.

- Clamp its long side in the clamp.

- Bend the short side of the product.

Bending metal-plastic and aluminum pipe

Bending alumoplastic pipes most often occur for turns of “warm floors”.

It should be remembered that for every 1/2 of the bent centimeters should be no more than 15 °.

Special springs

The softness of metal and plastic in most cases is an advantage of pipes. However, sometimes it turns into a minus. For example, when products have to bend along radii approximately equal to their cross section. A small bend radius often leads to fracture of the element.

It leads to a strong narrowing of the cross section, and hence the patency of the pipes. At the fracture site, the outer and inner layers of the product are partially destroyed.

Sometimes this entails damage to the reinforcing layer and the rupture of the pipe wall.

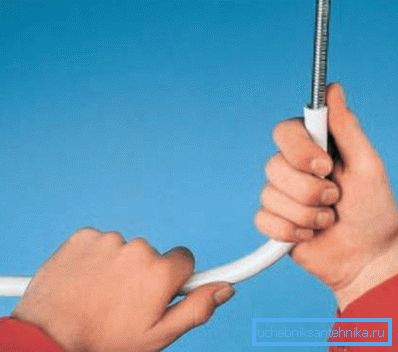

Note! It is possible to get rid of the described problems if a spring is used for bending metal-plastic pipes. This device ensures uniform bending of the product, without its creases over the entire turning radius.

- Springs are made in pairs: the device combines the inner and outer parts. For each diameter of pipes produced its own pair.

- The instruction recommends choosing springs from flat rather than round wire. Such a device will be less destroy the inner space of products made of soft polyethylene.

- The interior of the device has a conical end. This simplifies its movement to the fold area. The other side of the spring has a loop.

- A wire or cord clings to it, with their help the device is pulled out after use.

- The outer spring on one side has an extension that looks like a funnel. It is designed to facilitate movement of the tool to the bend area.

Work with the device

Pipes from metal-plastic have low rigidity.

This quality simplifies their bending.

- Having carried out the operation of bending the pipe to the desired angle, you can slightly take it back. So you release the inner spring and calmly remove it without destroying the polymer inner layer of the product.

- The location of the inside of the device can not be checked visually. Therefore, you should follow the length of the wire attached to it. This parameter + the length of the spring itself will be equal to the desired distance from the end of the pipe to the bend point.

- Alumoplastic should be bent not immediately, but with the help of a few rocking movements. This ensures that the inside of the plastic will not hesitate, and be distributed along the bend radius evenly.

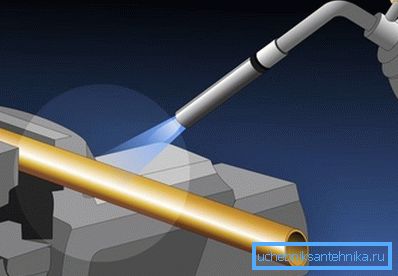

Steel pipe bending

Bend the steel element can not only the factory fixture for bending pipes.

There are "popular" ways of processing items.

- Secure the item in a conventional vise.

- Heat the fold with a gas heater.

- You can begin to form the desired angle of the product.

Note! You can find out if the pipe is sufficiently heated by its color. If he became scarlet, then it’s time to act. It should be warned that the method of heating is not applicable for galvanized products.

A little bit about how to bend a profiled pipe (square, rectangular shape) with a small section.

- Sand the element.

- Close its ends with wooden pegs.

- Substitute the supports under both sides of the pipe.

- Begin tapping gently with a rubber mallet in the center of the element, giving it the desired shape.

Bending solid plastic pipes

Equipment for bending plastic pipes can also be replaced with a simple fixture.

- Make a frame of the fiberboard to give the element the desired shape.

- Sand the workpiece with emery cloth.

- On the molding machine, make a silicone shell for the plastic part. It is needed to fix the pipe on the mandrel and protect the product from damage.

- Insert the PP or PE pipe into the shell.

- Secure it in the arbor.

- The resulting design set on the molding machine.

- After heating, the plastic will become soft and will settle on the mandrel, thus obtaining the desired shape.

- Wait 10/12 minutes.

- Remove the product from the design and allow it to cool completely.

The price of such accurate processing will be very small.

Conclusion

Having mastered the information obtained, you will learn how to bend in the living conditions of the pipe. They can be made of different materials and have a different diameter. The video in this article will help you understand the intricacies of the process.