Pipe flanges: species and features

Currently, there are several ways to connect water pipes, which differ in their characteristics and methods of installation. Each designer in the development of such systems pays special attention to this moment, since not only the quality of the final product, but also the cost depends on this moment. In this case, the flange connection of steel pipes or PVC materials deserves a separate description, since it is designed for specific features and high loads.

Species and Specifications

To begin with, it must be said that such a compound is usually used for materials with a large diameter. Therefore, the flange for a 25 mm pipe can be considered one of the smallest. However, this decision is not due to the lack of other types of docking, but with questions of elementary economy and the ability of such products to withstand high pressure.

Metal systems

Most often the flange connection of pipes is used when working with metal systems.

It has the form of two flat rings with holes, which when joined together coincide with each other.

- They fix such rings by welding on the end of the pipes, boiling the joints inside and outside. In this case, the installation manual strongly recommends that you pre-mark the place of fixing the flange relative to the mounting holes. Otherwise, you can get problems with the connection as a result of a mismatch of attachment points.

- Usually between these joints install a rubber gasket. It ensures the density of the junction and will avoid distortions, even if the work is done by hand.

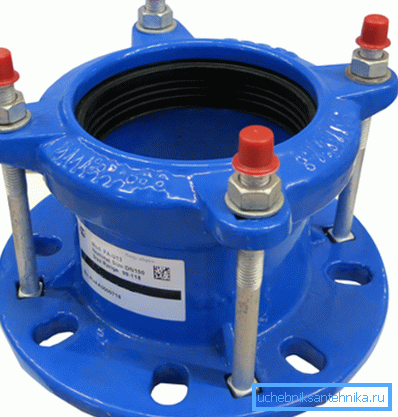

- Separate attention is deserved by systems from metal which do not accept the use of welding.. For them, specially designed structures that can be fixed with additional fasteners. A prominent representative of such products is a crimp flange for cast iron pipes.

Tip! Professional masters in recent times use only crimp elements. This avoids the use of welding, which significantly reduces the cost of all work.

PVC or PE systems

With the popularity of plastic pipelines, it becomes necessary to dock them with other systems, which means that we need a special crimping flange for polyethylene pipes, which will be worn even on metal. These products immediately solve the problem associated with the creation of virtually any design, and even just an elementary replacement of a part of the metal trunk with an alternative one.

It is worth noting that the flange for PE pipes is usually chosen for the assembly coupling, since it consists of two parts and there is no need to select other products for it. However, at the same time, professional craftsmen recommend immediately paying attention to the diameter, since it can be different. This is due to the fact that its purpose may be to connect pipes of different material or it must provide a transition from one diameter to another.

You also need to say about the fixing flange for PE pipes. It allows you to hold the structure in one position and fix it, reducing the load on the joint area. These products are used most often in combined installation.

It is important to note that sometimes flanges for polyethylene pipes are the only type of connecting elements for plastic systems. The fact is that professional craftsmen have long since abandoned docking sleeves, which have the form of ordinary sewer fittings, only of large size. This is due to the fact that during their installation it is necessary to withstand the level of the pipes as much as possible, otherwise leakage may occur.

Tip! Experts recommend the use of connecting elements of the same manufacturer, which manufactures the rest of the system. This will avoid problems associated with standardization and incompatibility.

Recommendations of specialists

- Buying flange connection of polyethylene pipes it is necessary to pay attention to the sealing gum. They should not be damaged and in size must fit the seats on the product.

- Usually a flanged adapter for PE pipes is sold for a specific type of product or when using material from the same manufacturer. However, if you can not find the desired configuration, then you should pay attention to the products that make third-party manufacturers who have no relation to the creation of the pipes themselves. At the same time, it is necessary to test the product on the spot to make sure it is consistent.

- It is important to remember that the price of these types of docking materials can be quite high, but this is completely offset by the ease of installation and disposal of expensive equipment. (See also Butt-Weld Pipe Article: Features.)

Conclusion

After reading the video in this article, you can get additional knowledge about this type of connection. In this case, based on the text above, it is necessary to conclude that these products are considered among the most practical and reliable.