Pipe taps and other tools for manual threading

What kind of tool is a pipe tap? How does the plate differ from the screw die, and does the wheel differ from the ratchet? How to cut internal or external thread with your own hands? In what cases are preferred threaded connections for water supply, and when - welded? In the article we will try to answer these questions.

Definitions

First we define the terminology:

- The tap is a device for cutting and sweeping (cleaning from scoring, rust, etc.) of internal threads. In our case - pipe.

Useful: pipe thread differs from metric one in that its size is characterized not by the actual diameter of the ridges or cavities, but by the conditional passage (DU) of the attached pipe or fitting.

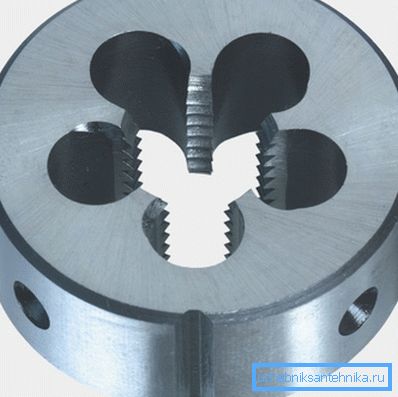

- Die - external threading tool, made in the form of a carbide nut with openings for chip removal.

- Klupp differs from the plate in that it consists of several separate sectors. Why do you need it? The fact is that hard alloys and high-speed steels used in the manufacture of rifled tools are more than expensive. Meanwhile, strength and hardness are required only for the ridges that directly cut the thread; the rest of the plate only combines a few ridges together. In the case of a die, this function is transferred to the holder.

- Vorotok - frame for the tap or dies, equipped with a pair of handles, used as levers. Allows you to cut the thread without any extras.

- The holder (mandrel) is, simply put, a round or hexagonal knob without handles.. Why is it needed? In practice, plumbing are not uncommon when the thread has to be cut not in a vice or clamp, but directly on the liner or riser against the wall. The handles will prevent the tool from turning, and the mandrel can be rotated with an ordinary gas wrench.

- Ratchet - crank with one handle, double body and reverse clutch. He also allows you to cut the thread against the wall. Unlike the mandrel, on which the gas key leaves a teaser, the ratchet does not receive mechanical damage in the course of the work, and it is much more convenient to use it.

It is curious: on sale you can find electric screw plugs for pipes, allowing you to do without physical effort. The pipe is clamped by its own clamp tool; the cutting tool is driven by a low-power electric motor through a gearbox. The tool is quite convenient to use, but its price - from 20 to 80 thousand rubles - makes the purchase expedient only for professionals.

Detailed description

Tap

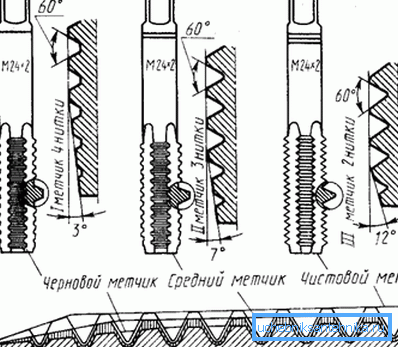

Externally, the tool resembles an ordinary bolt, ending not with a cap, but with a short square shank. By the beginning of the thread, the size of the ridges is reduced, which ensures the smoothest entry with minimal effort. The tap is equipped with longitudinal grooves, diverting chips.

As a rule, when cutting threads, a set of two or even three tools is used. For example, when cutting a half-inch thread, the future coupling (drilled cylindrical workpiece) first passes a rough pipe tap 1: 2, then finishing. When cutting in one pass increases tool wear, and the quality of the thread is much worse.

Dice

Besides the fact that this tool is designed for external threading, the plate is distinguished from the tap by another feature: the thread is cut in one pass.

What does a die look like? If a 1 1: 2 pipe tap looks like a one and a half inch bolt, then the corresponding die predictably resembles a half inch carbide nut. It is distinguished from a usual nut by a thread with the same smooth (conical) approach and several through channels for chips.

Useful: intake (conical) part of the plate has a length of 2-3 turns; total thickness corresponds to 8 to 10 turns.

On the outer cylindrical surface of the die there are several conical depressions, against which the screws fixing it in the holder rest.

Klupp

We have already described its fundamental difference from a die: the incisors are fastened only with a mandrel and can change when damaged independently of each other.

It is useful for a potential buyer to know only one subtlety: if the outer diameter of the die is strictly regulated by GOST 9740-71, according to which they are made, then the cutters of the screw die can have a different shape and be fixed in different ways.

When buying a replacement, it is better to pay attention to the products of the same manufacturer that made the mandrel. Otherwise a situation is possible when the incisors simply do not fall into place.

Pipe threads

In general, for a locksmith, information about pipe threads does not have much practical value.

However, for educational purposes, we present some interesting facts.

- There are cylindrical and tapered pipe threads. All plumbing equipment is designed to use cylindrical threads, and tapered are demanded mainly in high pressure pipelines.

- At diameters greater than 6 inches, pipes are welded or joined with flanges.

- Despite the large scatter of nominal diameters, regulating the cutting of pipe cylindrical threads GOST 6357-81 provides only four thread pitch.

| Thread pitch, mm | Number of threads per inch |

| 0.907 | 28 |

| 1,337 | nineteen |

| 1.814 | 14 |

| 2.309 | eleven |

Reference: English inch is 2.54 cm. Accordingly, a pipe tap of 2 1: 2 is designed for threading compatible with pipes with a conditional passage of 2.5x2.54 = 6.35 cm (63 mm).

- The binding of nominal diameters of pipe threads to the metric measurement system is also governed by the standard mentioned above. Here is a list of some sizes:

| Nominal diameter, inches | Step between threads, mm | The average diameter of the internal thread, mm | Average diameter of external thread, mm |

| 1/2 | 1.814 | 19,793 | 18,631 |

| 3/4 | 1.814 | 25,279 | 24,117 |

| one | 2.309 | 31,770 | 30,291 |

| 1 1/4 | 2.309 | 40,431 | 38,952 |

| 1 1/2 | 2.309 | 46.324 | 44,845 |

| 2 | 2.309 | 58,135 | 56,656 |

| 2 1/2 | 2.309 | 73,705 | 72,226 |

Thread or weld

Risers and liner heating systems and water supply have a nominal diameter, obviously much smaller than 6 inches. Accordingly, for the installation of compounds can be used as welding and thread.

Obviously, less time is spent on the welding side: an experienced welder spends no more than 10 minutes on a butt joint; threading, assembling and sealing the joint will require at least three times as long at a noticeably greater expenditure of effort.

When threaded connections justify themselves:

- If you have problems transporting the tool. It is clearly easier to bring a plate with a holder and a pair of gas keys to the dacha by public transport than an electric welding apparatus, and even more so - a pair of cylinders and a set of hoses with a torch.

- If necessary, make the connection collapsible. A typical case is a sgon after a valve on a steel water pipe. Sooner or later, the valve will need to be replaced, and the pipes will need to be cleaned of mineral deposits; the ability to do this work without welding is a definite advantage.

- Finally, the threads have no alternatives if galvanized pipes are used for the installation of communications. The fact is that the weld seam breaks the thin zinc layer, which makes galvanizing useless: corrosion destroys the seam area at the same speed as when using VGP pipes made of black steel. But with the threads, the situation is changing radically: the zinc layer remains intact, with the result that the resource of the pipeline increases several times. The author had to open the galvanized heating towers assembled on the threads after half a century of operation; if the top multilayer painting prevented assess the condition of the pipes, the internal examination showed that they are no different from new ones.

How to cut a thread

Internal

Suppose we have a drilled steel billet for a 32 mm (1 1/4 inch) DU steel coupling. We need to turn it into a finished coupling.

How to do this job?

- Clamp the workpiece in a special clamp with a diamond-shaped lumen between the jaws.

Pay attention: it is undesirable to use a vice in this case. Compressed from both sides of the workpiece is deformed, will become ovality.

- We put the rough pipe tap 1 1: 4 inches into the knob.

- Lubricate the inner surface of the workpiece. Lubrication will reduce the resistance when cutting and reduce the likelihood of scoring. What kind of lubricant to use is all the same: oil for sewing machines, autol, grease and even diesel fuel are equally suitable for our purposes.

- We position the taper strictly along the axis of the future coupling, press it to it with maximum effort and turn it without disturbing the positioning and without loosening the pressure. Cutting without pressing the tap to the part is possible only after 2-3 complete turns; if you weaken the force earlier, the first string will be torn off.

- Having passed the coupling with a rough tap, remove the knob and remove it from the other side. Repeat the operation with medium and fine taps.

What to do if you have only the usual grip:

- They clamp the shank of the tap.

- The workpiece is clamped with a gas (pipe) key and mounted on its entry.

- Further operations are identical to those described above.

Useful: if the tap is used only for the threading of used fittings, it is enough to have only a finishing tool in your collection.

Outdoor

Here the thread cutting instruction includes preparation of the approach for the plate. In order that cutting does not require an excessively large clamping force, a chamfer should be cut from the outside of the pipe at an angle of about 30 degrees to its axis.

Consider how you can prepare a call, so to speak, in the field:

- Wiping around the edge of the pipe grinder with a circle on the metal.

- Doing the same job with a hand file.

- Finally, in the absence of a tool, the edge of the pipe with a little skill can be simply compressed with a gas wrench. The main subtlety of this operation is not to overdo it and not to give the pipe ovality.

What to do next:

- The outer surface of the edge of the pipe is smeared again.

- The plate is pressed against the end face strictly perpendicular to the longitudinal axis of the pipe. The clamping force is maintained until 2-3 complete turns are made.

- Next is simple mechanical work: a die is chased along a pipe until a thread of the required length is obtained. Sharply increased resistance means scuffing chips; in this case, the plate is driven back one turn, the chips are removed, and the surface is relubricated.

When threading an external thread directly on the riser or liner there is one subtlety. The pipe on which the thread is cut is necessarily held by the gas wrench so that the force on it compensates for the torque that occurs when cutting.

The fact is that it is much easier to tear the liner from the riser or the riser from the neighbor's battery than it might seem: the lever allows you to develop a very significant effort. In addition, the condition of the pipes themselves in the old housing stock often leaves much to be desired.

Conclusion

We will consider our acquaintance with the tools for manual threading and process technology held. As usual, the video in this article will offer the reader additional information. Successes!