Plugs for pipes: the purpose and types

How much time is used in plumbing pipes, so many stubs exist on them. These details are usually paid unfairly little attention, and in fact they are also part of the integrity of the entire pipeline and must clearly perform their functions. In this article we will consider their main types and purpose.

Purpose

Plugs are used in the following situations:

- During pipe transportation. This helps to prevent the product from getting internal damage.

- For the implementation of the blocking of the end of a branch of water supply, sewage or gas pipeline. After all, all pipelines must end somewhere, and it is the plug that is responsible for the necessary sealing of such a place.

- When repairing a damaged area. Especially if it is impossible to turn off the entire system, and it is necessary to isolate the recovery site by stopping the flow of the contents of the pipeline.

Species

First of all, the plugs are distinguished by the manufacturing material.

Material

There are two state standards that determine the material of a suitable product:

| GOST number | Definition |

| 17379 - 2001 | The material of the cap must comply with the pipeline material:

|

| GOST 18599-2001 | For pipes with a small section, regardless of their material, it is allowed to use plugs made of low-pressure polyethylene |

Tip: if you need to stop the flow of aggressive substances with a high temperature, it is recommended to use only steel plugs. Although their price is higher than plastic counterparts, but they are able to withstand higher pressure and heat up to 600 aboutWITH.

Fixation method

Operational instructions suggest four main options for fixing the plugs:

- Bolts. This type of fastening requires the presence of special holes-lugs on the pipe itself, which imposes some restrictions, and the additional use of the sealant necessary to increase the level of sealing.

Tip: It is recommended to use this type of connection for interflange models that are designed to stop the movement of fluid between parts of the pipeline without completely dismantling it. That is, in the case when access to the end of the pipe is limited, and it is possible only to twist the overlapping plate, which is inserted into the narrow slot, with bolts.

- Thread. The most convenient to use with their own hands and reliable method of attachment. Threaded channels can be cut from the outside or inside of the product, as long as the pipe has similar processing. You have probably come across such a method of sealing in everyday life, twisting the caps of bottles, cans or cans, and you can judge it efficiently by hearsay.

- Welding. How to stop pipe without thread? In this case, you will need the welded representatives of the components considered and the welding machine.

The undoubted advantages of this method:

- No need for connecting elements on the pipe itself. That is, you can brew any section of the pipeline.

- High reliability and tightness.

But there are also disadvantages:

- The difficulty of dismantling or replacing if necessary.

- The need for special equipment and the ability to use it.

- Limited to metal products.

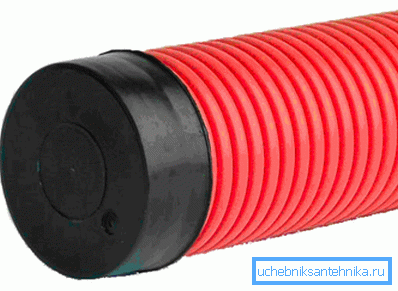

- Insert - the simplest, cheapest, but at the same time the least efficient clogging option. We mentioned above the use of plastic products for sealing polypropylene or metal pipes, and so it is implemented that way.

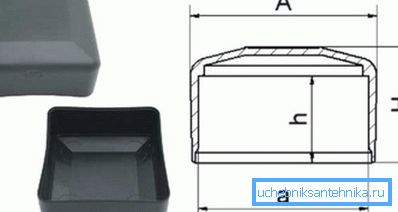

Of course, that such a method will withstand high pressure speech and can not be, but for overlapping free-flow areas it is quite enough. It is noteworthy that it is excellent for profile structures.

Place of application

For plastic products, due to their elasticity, there are two possible uses:

| Option | Special features |

| Interior | The docking part is inserted into the pipe, almost completely hiding in it, which gives the whole structure greater aesthetics |

| External | The cap is worn as a cap on the end of the pipeline, which is possible even if it is clogged. |

The form

As for the forms, they can be very diverse in accordance with the section of the pipe: a circle, an oval, a rectangle, a square, and so on. In this case, the protruding part is usually flat or convex.

Conclusion

The pipeline always ends somewhere, and sometimes it needs to be repaired. In either case, you will need stubs to shut off the flow of matter passing through it. They differ in material, method of fixation, place of application and form, so that you can always choose the most optimal product for your particular case.

The video in this article will provide you with additional information regarding the materials presented. Make your choice in accordance with the recommendations given.