Protective asmolno-polymeric tape for pipes

Protection of metal water pipes with drinking and industrial water, gas and oil pipelines today is a priority. Damage to them can lead to great financial and environmental damage. In the article we will consider an asmolno-polymeric tape which will help to cope with it.

Why she

The negative impact of the environment on the metal was the impetus for finding ways to avoid costly repairs, by increasing the service life of existing pipelines (see also the article Brass Tube - the secret of popularity).

One of the options - insulating asmolno-polymer tape, reliably ensuring their protection. It can be used in the planned repair of engineering networks, which are used for a long enough period, and it also eliminates leaks in case of accidents.

Properties and Views

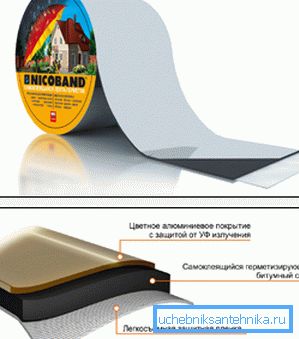

The product is made of polymeric materials on which a mastic layer is applied with a thickness of about 2 mm. It consists of:

| Mastic layer | Complex mastic composition on the basis of asmol, providing effective protection of pipelines from exposure to aggressive environment. |

| The basics | Polyvinyl chloride or polyolefin tape. |

| Adhesive material | The adhesive layer is used to prevent sticking of the tape supplied in rolls during transport and storage. |

The range of use of the material is -100? C - +300? C environment.

The following insulation grades have been developed:

- Summer (L) - the instruction recommends using the product at temperatures from + 50- + 300? С, while the pumped product should not be heated above +400? С.

- Winter (G) - the lowest indicator is -200? C, the upper parameter of the range is up to 100? C, the transported medium must have a temperature of up to +400? C.

- Heat resistant (T) - it is allowed to use the tape in the ambient temperature range of -100? C- + 300? C. The pumped medium can have a temperature of up to +1500? С.

The width of the polymer asmol tape is 90-450 mm.

Application

- Asmol-polymer tape is manufactured in industrial conditions and delivered to the work site in rolls already fully ready for use.

- For applying to the pipeline is used special insulating machines, it does not require cleaning the surface and its heating, if the process occurs in the winter. In fact, it can be recognized that such a tape is the only insulating material that has no restrictions for laying on temperature conditions, due to which the price of work is reduced.

- On its basis, a method called “cold” coating has also been developed, referring to reinforced coatings. This protection is a multi-layer system consisting of a polymer-asmol tape and an asmol primer.

- The pipe cleaned to the IV degree of cleaning is covered with a uniform layer of asmol primer.

Tip: do not use a different type of primer, as this is what Asmola has a special formula that provides the connection of the metal surface of the pipeline and mastic on a chemical level.

- Use a special primer for application or use your own rollers.

- Then on the dry layer of primer should be wound tape, overlapping the previous round of the next half.

Tip: Make sure that PVC tape is applied to the pipe inside with a mastic layer in a spiral and does not have distortions, wrinkles and sagging and wrinkles. Do not forget to remove the anti-adhesive layer from it before the process.

- If it is necessary to carry out protective work on the main pipelines, insulating machines are used, which can simultaneously remove the old insulation, remove the release layer and wind the new insulation tape.

- For manual isolation of pipes, mechanisms resembling a “squirrel wheel” are used. In this case, you need to be prepared that the consumption of asmol-polymer tape will increase by 10%.

Material advantage

As mentioned above, the main positive characteristic of the tape is its ability to work under virtually any temperature conditions. Such a quality could not exist if it were not for the structural structure of the material itself.

Due to the high adhesive qualities of mastic, it does not peel off from the polymer base. The mastic layer is an ideal layer resistant to tension and temperature changes and tension.

Below we consider other positive qualities of the material, which allowed it to gain wide distribution in the fuel and energy and utilities sphere:

- Due to the chemical bond between the metal of the pipeline and the insulating material, high adhesive qualities of the tape are maintained for 30 years, which is an excellent indicator for such works.

- The use of zones of overlap, as well as due to the tension of the polymer base along the transverse and longitudinal seams, does not form bulges or tent formations.

- It is able to protect pipes from electrical voltage. For example, the film reliably isolates the main line from cathodic polarization, preventing the formation, as well as the development of corrosive sites, which may be due to this.

- The material has a high resistance to mechanical stress, soil corrosion and cathodic peeling, therefore it has proven itself well when laying gas-oil pipelines. With its help, all special conditions and requirements for construction are observed, the reliability of operation of the highway increases. The use of polymer-asmol tape allows laying pipelines in soils of any corrosiveness and humidity.

Conclusion

Metal can not yet boast the ideal characteristics, therefore, to protect it, use different materials, for example, a special insulating tape. With its help, the surface of pipelines receives additional protection, which allows increasing the service life of highways up to 30 years (see also the article “Boiler pipe” as a key element of the equipment of heating systems).

The video in this article will help you find additional information on this topic.