Rollers for profile pipe: types, principle of operation,

How can a square or rectangular section be shaped with a regular arc? How can self-made rollers for a shaped pipe be made? And what solutions does the modern industry offer? Let's try to answer these questions.

Why do you need it

Why do I need to bend a profile pipe?

Let's give some examples.

- The arc canopy is not only beautiful, but also practical: it will never accumulate snow.

- The curved visor above the porch looks much better than a simple design with one ramp.

- The arched greenhouse is exceptionally durable; it perfectly withstands snow and wind loads.

By the way: the assembly of greenhouses from shaped pipes is a good business, requiring the presence of only the notorious pipe bending rolls and welding machine.

Types of rollers

What they actually are?

Mechanical

The simplest design is a mechanical three-roll mill. Such machines can often be found on sale; their price starts from about 15 - 20 thousand rubles. How are they arranged?

In full accordance with the name, the construction is based on a proftrub with three rollers. One of them may be displaced relative to the other two in a direction perpendicular to the plane uniting them; a screw mechanism is used for displacement, which allows even a person with quite ordinary physical capabilities to develop significant effort.

One of the rolls is supplied with a handle, which allows rotating it and thereby pulling the pipe to be bent.

There are several modifications that allow several to improve the performance of the pipe bender:

- Combining the rolls with a common chain will ensure their synchronous rotation., thereby preventing the pipe from slipping.

- A gear can be used instead of a chain..

- The use of hardened rolls increases their resource several times.

- In addition, the rolls can be replaceable., what will allow to bend without jams both profiled, and round pipes.

Electric

In this case, part of the handwork is shifted to the electric motor.

On sale you can find two options for the execution of electric pipe benders:

- In simpler solutions, the electric motor is only responsible for drawing the pipe. The positioning of the bending roll is made manually.

- Advanced models of rollers use electricity both for pulling and for shifting the roll (of course, by means of a gearbox that multiplies the force).

Hydraulic

This category includes both powerful industrial machines weighing tens of tons, and relatively compact devices. Their common feature is the use of a hydraulic cylinder: pumping oil pressure in it, you can develop a huge force on the deforming roll.

Bend radius

Regardless of the device of the pipe bender, there is a general pattern: the greater the thickness of the pipe (its cross section parallel to the bend radius), the greater the minimum bend radius. We give the values stated for their machines by one of the domestic manufacturers - they are quite typical.

| Size of pipe, mm | Minimum bend radius, mm |

| 15x15 | 280 |

| 20x20 | 280 |

| 25x25 | 280 |

| 30x30 | 325 |

| 40x20 | 325 |

| 50x25 | 400 |

| 40x40 | 900 |

Without pipe bender

Is it possible to bend an arc out of a shaped pipe without rolls?

Technically, this is possible, but the result is likely to be unsatisfactory.

The instructions for bending are not so much complicated as they require a large amount of preparatory work.

- A template with a surface shape corresponding to the arc you need is made of wood or plywood.

- A loop is attached to the template — a retainer into which one of the ends of the pipe is inserted.

- Further work, in fact, comes down to the application of brute force at its second end. To increase the effort can be used a variety of levers.

crazy hands

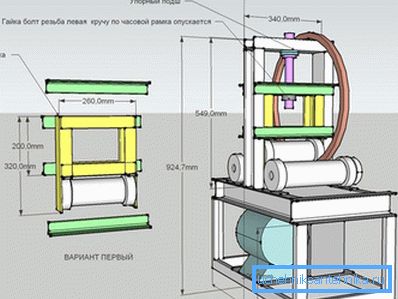

Various schemes and drawings of rolls for a profile pipe do it yourself in recent years have literally flooded the Internet.

We will immediately disappoint the most economical readers: some of the details will have to be ordered.

Which ones?

- Themselves rolls. They can be cylindrical, or with grooves for bending round pipes.

- Clips for bearings.

- When using a chain transmission - asterisks.

Of course, without reference to a specific design, it is a thankless task to give advice on the assembly of rollers.

Let's try, however, to heed the recommendations of the owners of self-made devices, highlighting the main points.

- The drive handle must have a rotating handle. Otherwise, the first calluses on the hands will appear within a few meters of the outstretched pipe.

- Bearings are better to take self-centering. To mount both bearings of each roll exactly on the same axis at home is not a real task; the slightest misalignment will increase the pulling force.

- The screw driving the pressure roll can be taken from the old vice.

By the way: an alternative to the screw mechanism is a car jack of any type. It will allow you to develop a huge effort with minimal application of your own strength.

- As a bed it is better to use a segment of a channel of a suitable size. The bending force of the bed will be very significant; A welded frame made of a corner or a thin pipe can simply bend over.

Conclusion

We hope that the material offered to the attention of the reader will help him choose or make a tool to his liking. As always, you can find additional thematic information in the video in this article. Successes!