Sandwich pipe for a bath - consider the key features

Despite the emergence of various alternative heating methods, until now it is wood-burning stoves that are the most popular solution for home-made baths. But to ensure safety and comfortable bath procedures it is necessary to take care of the correct removal of smoke from the room. We will tell about it further.

Why do we need such a construction

Any heat source that uses the energy of a burning fuel carries two serious problems:

- Fire hazard The incandescent elements are able to set fire to walls or any items made from combustible materials.

- Thermal expansion Hot mines expand when heated. For this reason, the design should leave gaps.

As a result, there is a need for such a channel that will transfer as little heat as possible to the outer surface. Also be sure to achieve a minimum degree of thermal expansion. Chimney sandwich meets these requirements, so its use is very reasonable.

Basic information

We now turn to the specifics and get acquainted with all the nuances that characterize these products. Remember that the completeness of information will allow to achieve the desired result in any business.

Comparison of stainless and galvanized steel

Until recently, masonry structures were used to ensure the correct exit of smoke to the outside. But with the advent of new and more advanced technologies, this option began to gradually recede into the background. The popularity of galvanized and stainless steel is increasing every year, but which one is better?

Of course, at first glance, the answer is obvious - the stainless steel furnace sandwich pipe is much better.

Therefore, we note the main advantages of this material:

- Highest Corrosion Resistance. In this aspect, "stainless steel" is the best option.

- Resistance to high temperatures. Even if you regularly warm up the steam room to extraterrestrial temperatures, it will not adversely affect the coating.

- As a result of the above qualities - long service life.

- Attractive appearance. For many people, this factor sometimes comes to the fore.

As for galvanized coatings, they can not boast of such properties. However, they have another important quality, which today is often the decisive factor when choosing - low price (compared to stainless steel). However, if funds allow, it is better, of course, to prefer stainless steel.

Key requirements

When planning the installation of a chimney sandwich, you should know what requirements are imposed on this product.

Therefore, we will provide them compactly:

- The cross-sectional area should not be less than the size of the discharge pipe.

Tip: Experts believe that the optimal channel length is 5 meters. It will allow the system to function normally.

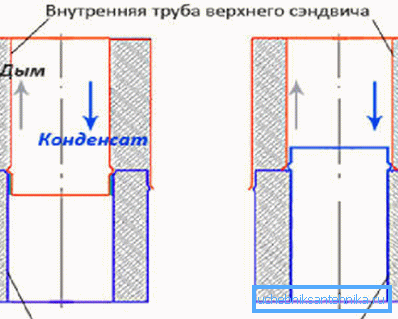

- In the finished product should not be ledges, and it must be placed vertically. The maximum tolerance is 30 degrees, and the horizontal offset can be no more than 1 meter.

- If the roof is made of combustible materials (for example, bitumen or tile of wood), then at the end of the chimney should install a pipe deflector with a grid, in which the cells are not more than 5x5 mm.

- Places where pipes sandwiches for stoves pass through ceilings need to be treated with insulating materials.

- If the mine is supposed to be of horizontal shape, then its length should be no more than 1 meter.

Note! To ensure proper security, it is necessary to check the entire system at least once a year. Evidence of possible problems may be the presence of soot and soot.

- Do not dock the elements in the plane of the roof and floors. The fact is that such places should be visually accessible in order to check them if necessary.

- It is strictly forbidden to contact the chimney with other communications (ventilation, wiring, gas, etc.).

- Also, the instruction prohibits the use of a sandwich pipe as the first element when connecting to the nozzle.

All the rules and requirements that were presented above are specified in SNiP 41-01-2003. (See also the article Passing the pipe through the roof: features.)

Ways of mounting modular elements

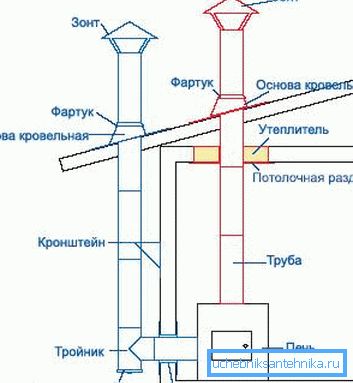

There are two installation options: “by smoke” and “by condensate”.

They have their own characteristics:

- The first technology is used in those situations when there is a need for 100% to prevent the ingress of carbon monoxide into the room. They spread through the gaps in the ceiling.

- The main purpose of the second technique is to allow the condensate to flow down freely. It is formed due to a significant temperature difference. This technology provides a long life of the insulating material, since it is not affected by moisture.

You do not know which of the presented ways to choose? Of course, the method of "smoke" is preferable, because it protects the human body. However, if you make a high-quality sealing of the joints, then additional safety measures will not be required, and the second technology seems to be a more rational choice.

Conclusion

On this positive note, we will summarize our story, but we have prepared for you an additional portion of knowledge. In the presented video in this article you will find additional information on this topic. After viewing this video, you will certainly be able to understand all the nuances.