Sewer drainage: how to choose the right products and dock

Currently, for installation of sewage systems in an apartment or a private house, separate ready-made elements are used, which allow without special efforts to construct a system of any complexity and configuration. To rotate the pipe at a certain angle are installed plastic sewers. Features of their design, the existing types and methods of installation will be the subject of today's material.

Purpose of the product

PVC pipes for domestic sewage are required for arranging the rotation of sewer pipes at a certain angle and are used for the installation of dirty water drainage systems in administrative and residential buildings.

Plastic connecting elements have a smooth inner space, which greatly reduces the risk of clogging during operation, and also practically does not emit noise when fluid flows through them.

In addition, a material resistant to the effects of hot water (up to 95 degrees Celsius) and chemical detergents is used for their production.

Sizes of sewer plastic branches: 110 and 50 mm (diameter of the inner hole is measured).

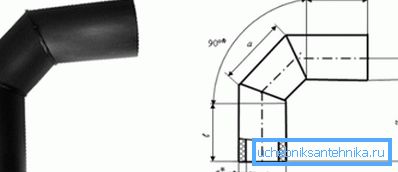

As for the corners, the standard values are:

- 30 degrees;

- 45 degrees;

- 87 degrees.

Tip! By combining the drainage and semi-branch sewer with different bending angles, it is possible to achieve a rotation of the pipe at 30, 45, 60, 75 and 90 degrees. However, it is advisable to avoid too sharp bends in order to avoid blockages.

There is another option: a branch pipe with a diameter of 110 mm with access to pipes of smaller diameter. They are used to create various non-standard configurations.

Types of bends

Regardless of the name of the manufacturer, which produces PVC sewer tap, all these products comply with accepted building standards (GOST). This facilitates the design of sewer systems, the purchase of necessary materials and their installation into a single system.

There are several different models of corner elements, which are distinguished by the price and some design features.

- Polyethylene. They are made of black material and are butt-joined or with the help of couplings. In the first case, the ends of the pipe and outlet are heated with the help of special equipment and are joined to each other until the plastic completely hardens. Couplings are already equipped with a special helix at the factory, which for sealed docking is heated by means of a welding machine.

- PVC bends. The most common type. They are connected by putting the bell on the smooth pipe. Advantages - no need to use various power tools and increase the speed of installation of the sewer system as a whole. Structural elements intended for use indoors, painted in gray. There is another drainage of the sewage system - in a private house (when the room is not heated or pipes are mounted on the street), the parts have a brown color. (See also the article Pipes for domestic sewage: features.)

Note! It is impossible to join these two varieties into one system. It is necessary to use bends of the same type. Otherwise, high-quality and long-term maintenance of sewage is not guaranteed. In special cases, you need to include in the scheme of special adapters.

- Polypropylene. They also have sockets and smooth ends for mating with each other. These products are used only in conjunction with pipes made of similar material. The main purpose - the removal of groundwater and wastewater. They are able to skip the flow of water at a speed of 4 to 7 m / s.

- Corrugated Pipe Bends. These elements are joined by clutches and provided with sealing rings on each side. At the point of inflection, the outer part of the product has a reduced diameter. Scope of application - docking pipes of various materials using sealing cuffs.

- Taps Wavin. Special, separately patented system. On the outer side of the corrugated element there is a kind of triangular recess that acts as a lock. For the manufacture of these products used high-quality material capable of withstanding high pressure. Guaranteed service life - 50 years.

- Taps Magnum. There are models with an inflection angle of 45 and 90 degrees. A special feature is the absence of rounding, which can cause blockages during the operation of the system. Connecting elements of similar design are practically not used in the creation of sewer systems.

Independent installation of taps

As mentioned earlier, PVC bends are the most widely used. This is due to their cheapness and ease of installation.

Docking is done by special seals. Often they are already inserted into the inner space of the socket. Otherwise, the rubber ring, supplied with the corner element, is placed in a special recess immediately before the connection.

There is an alternative method - the use of glue. This type of docking is less common and more complex. With adhesive bonding rubber seals are not needed.

Sometimes it is necessary to connect pipes made of various materials. In this case, you need to use sealing cuffs and sanitary sealants. Such a connection will be reliable and will not leak during operation.

Sealing of joints

Reliability of its operation depends on tightness of the corner joints of the sewer system. This should be given special attention, especially when the installation is done by hand. (See also the article Connecting the toilet to the sewer: features.)

Even more carefully should be sealed joints when laying pipes under the ground, which often happens during the construction of private houses. Leak repair costs can be quite substantial.

It is recommended to seal connections of pipe bends with pipes using special sealants.

These substances contain many components and are divided into two main types:

- acidic (cheap formulations);

- neutral (more expensive).

Note! Acid sealants should not be used when installing metal and cast iron pipes. Before you buy should pay attention to the composition indicated on the package.

Even if you join PVC seals on rubber seals, additional processing of the ring with a sealant will only add reliability to the joint.

The use of one or another sealing compound is mandatory for the treatment of sewage system joints with cast-iron pipes. By definition, this material cannot be absolutely smooth and therefore requires the use of current formulations. The best solution is liquid silicone.

Additional ways to seal pipe and pipe joints

In addition to using a sealant, alternative methods can be used.

| View | Description |

| Epoxy adhesive | Very reliable and durable connection. But after solidification of the composition, it will be impossible to disassemble the pipes without destroying them. |

| Hemp or tar strand | It is used for joining PVC outlets with pipes of other materials. In this case, the end is wrapped with the selected material about two-thirds of the length, inserted into the socket and filled with a cement or asbestos-cement mixture. The method is reliable and time-tested. |

| Technical sulfur | This method has recently been used in 95% of cases. Now it can be used to dock the sewage systems of different materials. |

| Bituminous mastic | It is more suitable for joining ceramic taps with similar pipes, but can be used to seal joints of external sewage from PVC pipes. |

| Sealing tape | The least reliable way. Suitable as a temporary measure to replace the damaged node. |

Elimination of leaks

Well, when the sewer system is operated without accidents. But if leakage occurs, do not despair.

The instructions in this section will help you quickly fix the problem.

- Leakage at the junction with old pipes. In this case, a liquid sealing compound will help: a sealant or a mixture of cement with glue. Epoxy glue or raw rubber will also work, in extreme cases - clay.

- Hole. It is treated with a peg, treated with a sealant, or a tire (yoke). Emergency option - the use of a rubber bandage.

- Longitudinal crack. Sealed with epoxy glue or silicone impregnated fabric. For iron pipes you can use cold welding.

- Chip edge of the outlet. In this case, only the replacement of the damaged item will help.

Conclusion

The duration of the operation of the system and the absence of leaks depends on the choice of high-quality outlets and other components, as well as on the correct installation. More details about this process can be found in the video in this article.