Soldering iron for polypropylene pipes: selection parameters

Polypropylene pipes are increasingly replacing more traditional metal counterparts due to low price and ease of installation. To carry out communications from pipes of this type, it is sufficient to have a specialized soldering iron and minimal skills to handle it. Before choosing a soldering iron for polypropylene pipes, you should pay attention to a number of qualities that have a direct impact on the installation process.

Equipment manufacturers are trying to keep up with progress, offering consumers various names of their own products. In such a variety it is quite difficult to navigate and there is a high probability of acquiring a soldering iron that is unsuitable for your purposes. Also, we should not forget that not every brand produces products whose quality is difficult to identify at first glance.

In this article you will be provided with detailed instructions on how to select a soldering iron for polypropylene pipes. It will describe the most important points to which attention should be paid before giving preference to one or another product.

Choice of a soldering iron

Power

The key technical characteristic of the soldering iron is the power of the heating element, which is measured in watts. Contrary to popular belief, the temperature of the soldering iron for polypropylene pipes does not depend on the power of the device.

This parameter determines the diameter of the pipe, which is guaranteed to be mastered by a soldering iron. The smaller the equipment capacity, the smaller the number of nozzles that can be included in the device and, accordingly, vice versa.

Soldering irons with a capacity of 850 to 1500V are designed for welding pipes with a diameter of 15 to 50 mm. Products whose power is certified from 1700V and above has a range of heating pipes up to 63 mm in diameter. On average, soldering devices with a capacity from 850 to 1200V are suitable for domestic purposes, and for professional installation it is better to use analogs with an indicator from 1700V and higher.

Note! The equipment power / pipe diameter ratio is not always linear, as some manufacturers produce 850V products, which do an excellent job with large-diameter pipes.

In some cases, some experts recommend multiplying the pipe diameter by 10, thus obtaining the minimum power value of the device. In part, this formula is valid, but it should be noted that in this case, the minimum acceptable value is implied, which does not ensure comfortable operation of the equipment.

Nozzles

Nozzles for a soldering iron of polypropylene pipes, most often are included in the basic package of the purchased device, however, in some cases, their quality may leave much to be desired. First of all, you should pay attention to the number of available nozzles - the more there will be, the correspondingly more possibilities the soldering iron will have.

If you are planning to engage in laying communications at a professional level, then it is advisable to foresee the possibility of installing several attachments at the same time. This circumstance is not critical, but at the same time, it significantly simplifies the installation process on a large scale.

When purchasing nozzles, you should pay attention to the presence of spraying, which significantly improves the performance of the equipment. Teflon-coated nozzles have shown themselves to be the most functional (in some cases, metallized Teflon is used) - they warm up evenly and will last you an order of magnitude longer than conventional counterparts.

Product Rating

Despite the fact that it is not possible to fully classify all products of this type, a tacit rating of soldering irons for polypropylene pipes has developed among the professionals, which to some extent reflects consumer feedback.

And although today the “origin” of the soldering iron is not so strongly reflected in its quality, soldering irons are, first of all, classified by the producing countries that supply equipment to the modern market.

- Czech. Czech-made soldering irons rightfully occupy the leading stage in our unofficial rating. In terms of performance, Czech equipment is unmatched;

- Turkey. Turkish production is a kind of “golden mean” - this product can be both high-class and low-quality equipment, depending on the manufacturer. Before purchasing, it is better to get acquainted with consumer reviews about a particular brand and only then give it your preference;

- China. Chinese products are the most common on the modern market - it is distinguished by its affordable price, but also frankly low quality. The saying: “Failure without a reason, a sign of Made in China”, in this case, fully justifies itself, although the low cost allows you to buy Chinese equipment “ONCE time”;

- Homemade counterparts. Craftsmen collect homemade soldering irons from spirals from irons, electric kettles and other electrical appliances. Self-made unit is unpredictable in operation, and it can be used only at your own peril and risk.

In general, equipment for soldering polypropylene pipes demonstrates a logical price-quality ratio. You can give your preference to cheaper products, but the likelihood that it will serve you for a long time and will be convenient in operation is extremely small.

Repair of a soldering iron for polypropylene pipes is a thankless task, it is much more rational to purchase initially high-quality products if you are counting on long-term operation.

Work with a soldering iron

Working with soldering equipment with your own hands is relatively simple - just follow a few basic points.

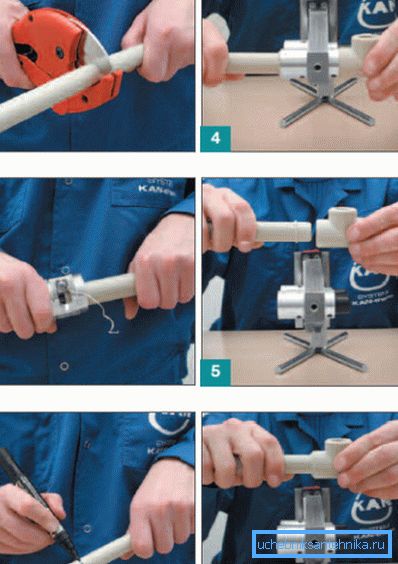

- The soldering machine is firmly installed on a flat surface. - to include the product in the network - preferably in a socket with a grounding contact. Nozzles are put on according to the pipe diameter;

- If the unit has a temperature adjustment function, then in standard situations it should be equal to 260 degrees C. When working with a soldering iron, it should be borne in mind that the time of heating and cooling of nozzles of different diameters is different;

- The device has several indicators that light up when you turn on the network - green means that the heating element heats up the nozzle, and red indicates that the temperature required for soldering is reached. After the indicator informs you of readiness, you can proceed directly to the soldering;

- Put on the pipe and fitting on the appropriate nozzles as smoothly as possible to avoid distortions on the connections. After 5 to 6 seconds, the plastic will begin to melt and you can insert the pipe into the fitting for the connection. It is strictly forbidden to scroll or make translational movements after the tube is in place;

Total

Having decided on which soldering iron is more suitable for your purposes, you will be able to select the necessary products with a high degree of probability. You can get more detailed information on this topic by watching the video in this article.