Tee for pipes of various materials

Whatever pipeline you carry out, most often you have to use tie-ins to it for more comfortable use. In this case, a tee (fitting) made of polymer or metal helps to properly arrange the junction of its branches. The article will be devoted to this element, without which it is difficult to imagine the supply or diversion of water.

Types of tees

It is better to classify products according to the type of material from which they are made. Even an alternative option - the method of installation, in the overwhelming cases, is based on this.

You can also combine two sorting methods to get an idea of the entire assortment of these connecting elements:

| Metallic | These include such fittings:

Most often, the tees are made by casting, for which they use:

Very rarely it can be welded elements. It can be said that the main advantage of metal products is their high strength. |

| Plastic | All products, including collet and welded fittings are made of polyvinyl chloride and polyethylene. But, separately, we need to consider tees made of PVC sewage pipes made of plastic that are installed in the socket or on the glue. The main advantage of polymer fittings for sewage is complete inertness to the environment and to the pumped substances, which allows them to operate until half a century. |

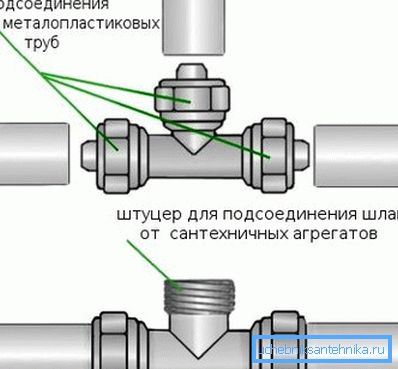

| Composite | These include connecting elements for pipes consisting of low-pressure polyethylene, equipped with bronze or steel bushings. Such fittings help to interconnect pipelines made of metal and polymers. The tee has a thread on the metal bushing side, crimped or welded installation on the polymer side. This makes it possible to include in the system instrumentation, for example, pressure gauges. |

Additional method

There is also another popular classification method that takes into account the working dimensions of a tee:

- throughput;

- threaded;

- average diameter.

But, it depends on the diameters of the pipelines and the relevant standards. The topic is quite extensive, so in our article it will not be covered.

Installation

Below we consider the general recommendations of the process when installing fittings on pressure or non-pressure pipelines that have a certain set of rules. Otherwise, the result of your work will be deplorable, not only for you, but also for your neighbors from the bottom of the riser.

Therefore, use the following recommendations:

- In pressure sewer systems it is allowed to use fittings with a right angle, in non-pressure fittings it is better to limit to taps under 45?.

- When assembling a free-flow network at the sockets, the instruction advises correctly orienting the connecting elements. In this case, the socket should be directed towards the liquid drain, i.e. the stream must first meet it, and then a smooth pipeline, otherwise the joints may leak. If we are talking about sewage, it will be very unpleasant.

- When installing the tee on glue, choose the position of the pipeline relative to the fitting within the first two seconds after their combination. Do not move or twist the knot after that, and if you are not sure of your capabilities, use guides.

Tip: when you connect a polymer tee with a plastic pipe with your own hands, at the last mark the depth of its insert. Otherwise, you can block access of fluid to the node.

- When assembling the metal piping, prepare the material for sgons and threaded ends. In this case, it is not recommended to save the fum-tape, the price of which is insignificant, and always use a locknut, before winding a few coils of the seal in between it and the end of the fitting, before tightening.

- Install plug-in connections, including collet and threaded, in well accessible locations..

Tip: when installing plastic or metal tees for pipes in hard-to-reach areas, use welding or press fittings (as a last resort).

Sewage

Thanks to modern materials, the installation of waste systems has become much easier and easier. Tees for plastic sewer pipes make it as easy as possible to manufacture any design scheme in private houses of different heights. At the same time, you will not be required to use sophisticated equipment or special tools.

In this case, use 3 types of tees that perform their special functions:

- For connecting vertical risers with horizontal pipelines, versions with angles of 87 ° or 90 ° are used.

- When creating horizontal branches - use products with an angle of 45 °.

- A coupling with an additional hole for repairs is called a revision. The third hole in it is twisted with a special cap, which gives access to the pipeline.

As experience shows, this is quite enough to create sewage networks of any complexity in a private house. Therefore, you should always rely on this type of connection.

Conclusion

From the article it became clear that for the implementation of the water supply to the building and its removal from it use water and sewer systems, having in their structure all sorts of tees. They can be made of metal or plastic and are selected depending on the type of pipeline. The video in this article will help you find additional information on this topic.