Truborez for steel pipes and other types of similar tools

It must be admitted, although polymers have penetrated into many areas of our life, where they can replace many of the usual materials, in plumbing are rare, but there are metal pipes. Mounting various systems, it is necessary from time to time to cut them for convenience at certain intervals. This article just will be devoted to tools that help to do it quickly and efficiently.

If you tried at least once to cut a metal pipe with a hacksaw for metal with your own hands or with a special disk, after that you had to refine the edges, which were uneven and not smooth. Truborez performs the same task, but much better and faster. Now let's see what companies offer us, producing such products for domestic and professional needs.

Types of tools

When choosing a pipe cutter, note immediately that it cannot be considered a universal tool. This is due to the different diameters of pipes that are installed for the supply of water, heating and drainage of sewage. Therefore, in each case, should be applied according to the material and size of products. If there are some models that are suitable for different types of pipelines, but this is most likely an exception to the rule.

Tip: before you go shopping, decide what material you have to work with.

There is also good news, but it concerns home craftsmen who can use a roller pipe cutter for steel to easily cope with both copper and metal-plastic.

Tip: Do not use tools designed for soft materials to work with steel. He will not be able to cope with it or deteriorate after the first time.

Wall thickness

Affects the choice and thickness of the wall of the product with which to work with the tool. Given this parameter, we can say that they can be for:

| Heavy loads |

|

| Thin-walled tubes | These include the following:

|

| Ceramic and asbestos cement products | Such pipes are usually used in sewer and waste systems. |

Design features

It is fashionable to distinguish the following types of pipe cutters:

- rotary or swivel;

- roller;

- telescopic;

- with ratchet;

- incisal;

- chain.

| Incisive |

|

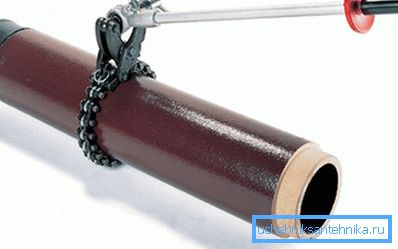

| Manual roller type |

|

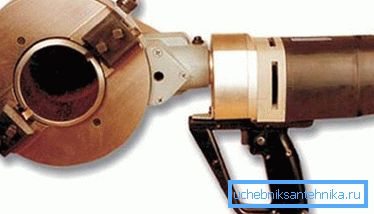

| Chain |

|

Operating principle

This is another way to classify a tool, it can be:

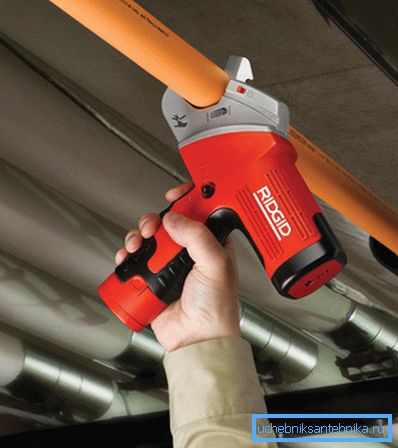

- electric;

- manual;

- pneumatic;

- hydraulic.

Most often in the home use a manual version, which is driven by physical force. Typically, such equipment is quite simple, its price is low, it does not require any special skills and qualifications.

Unlike the previous electric pipe cutter, it is significantly more expensive, but its performance is much higher. The device eliminates the use of physical force, has a high efficiency, so it is usually acquired for large-scale work.

How to choose

The most popular and numerous are pipe cutters for steel pipes.

With respect to other materials, it doesn’t look so bright.

- When working with copper, you should not forget that it is a soft metal that can easily be deformed. Therefore, a special pipe cutter for copper pipes is used to work with it.

Tip: in this case, a ratchet or telescopic tool is also made of steel, and their blade should be made of alloy steel.

- For working with thin-walled plastic pipes, special scissors are used, completely replacing the pipe cutter for plastic pipes.. Their main advantage is low cost and ease of operation. From minuses - hands will quickly get tired when cutting a large number of products, low-quality models come across.

Use roller and battery models:

- the first ones are cut with one cutting roller, rolling through several guides, usually they are not “hurried”;

- the latter cope with work much faster, but its maximum diameter is 42 mm.

- It is better to cut thin metal-plastic pipes with scissors, and use a pipe cutter for products whose O40 mm and more. A good choice would be a telescopic tool or a ratchet version, resembling scissors in appearance. The process is made by closing the handle.

Then you need to restore the cross section of the product, using a calibrator, which simultaneously removes the chamfer. The instruction allows the use of a tool for cutting steel pipes.

Conclusion

It has long been noticed that the use of various devices in the work helps not only to facilitate the process, but also to make it faster and better. The same can be said about pipe cutters, which make it possible to get a smooth, even cut. They are classified by design features and principles of action.

The video in this article will help you find additional information on this topic.