We select the tool for welding polypropylene pipes

It will not be difficult for a layman to install the pipeline with polypropylene pipes. The only thing is that this will require special equipment and, of course, some skills in working with it. In this review, we will consider in detail what kind of tool is required for welding polypropylene pipes and how to work with it.

General information

PP pipes are perhaps the most common type of plastic pipes, which is associated with a number of their advantages, such as:

- Strength;

- Resistance to high temperature and pressure;

- Durability;

- Resistance to temperature extremes, etc.

In addition, as mentioned above, their installation is easy to do with your own hands. It is carried out by soldering using pipe fittings. To do this, use a special electric welding machine, which is popularly called the soldering iron.

The principle of soldering is extremely simple - the device heats the junction points of the parts to the melting temperature, after which they are welded to each other.

In addition to the welding machine, it is desirable to have a pipe cutter and a stripper for pipes. The latter allows you to remove the top layer of polypropylene and reinforcement, which is necessary for reliable welding. Of course, in principle, these tools can be dispensed with, but they significantly simplify and speed up the workflow.

Types of soldering irons

Power

Equipment for welding of polypropylene pipes on the market differs primarily in power. This parameter determines the speed at which the device will heat the plastic to the melting temperature, as well as the diameter of the parts with which it will be possible to work.

The soldering iron for welding polypropylene pipes can have the following power:

| 680 W | Can be used for soldering parts with a diameter of 16 - 63 mm, which are usually used in home plumbing. |

| 850 W | Such a soldering iron for welding of polypropylene pipes is suitable for the installation of a pipeline with a diameter of 16 - 75 mm. |

| 1200 watts | Suitable for mounting parts with a diameter of 125 mm. |

For domestic purposes, a device for welding 680-850 W polypropylene pipes is quite suitable. For professional use, if you plan to work with large diameter parts, you will need a more powerful device.

Tip! Soldering equipment is relatively expensive. Therefore, it does not make sense to purchase it for one-time use. It is much more expedient to rent the device or to seek help from specialists who will install the pipeline themselves.

Equipment

The kit for welding polypropylene pipes must contain special nozzles that allow the installation of pipelines of different diameters. The more nozzles, so, accordingly, the tool is more versatile. As a rule, the number of nozzles depends on the power of the tool, since more powerful devices can work with a large range of diameters.

Nozzles differ in the material from which they are made. The best option is metalized Teflon, which ensures the reliability and durability of the tool.

Tip! A set for welding of polypropylene pipes must contain a special case that will ensure the safety of the device and all nozzles.

I must say that the nozzles differ in the method of attachment, they are:

- Cylindrical;

- Sword-shaped.

The latter are mounted through the through hole. For fixing the cylindrical nozzles, the soldering iron has a special mount. As a rule, cylindrical nozzles are used in a professional tool.

Note! The quality of soldering largely depends on the constancy of the temperature of the soldering iron. As a rule, the higher the price of the device, the better this indicator.

Soldering technology

As mentioned above, working with "polypropylene" is quite simple, however, before proceeding with the installation, you need to familiarize yourself with some of the features and nuances. Therefore, we will further consider the welding process in stages.

So, first of all you need to prepare the device for welding polypropylene pipes.

To do this, turn on the device, as a result of which two inductors will light on it:

- Thermostat indicator.

- Power indicator;

The welding machine is heated until the lights go out. As a rule, it takes 10-12 minutes. The heating of the device to the operating temperature will be indicated by the switching off of the second indicator.

However, the device after the first start consumes more energy, as a result of which the nozzles are heated to 300-320 degrees, which during welding causes deformation of the plastic. Therefore, it is necessary to wait for the second activation of the indicator and its shutdown. Only after that you can begin further work.

Once the unit is prepared, you can proceed to the installation of the pipeline.

The instruction is as follows:

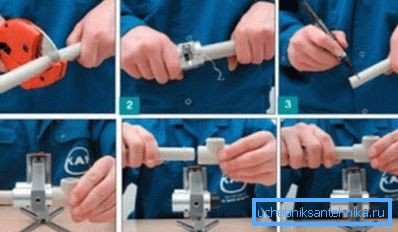

- First, cut the parts with a pipe cutter or other tool into pieces of the desired length.. To do this, you must have a scheme in which all dimensions of the pipeline elements will be indicated.

- If the material is reinforced, it is necessary to remove the top layer with aluminum reinforcement using a stripper.. It is very simple to work with the tool - the stripping is put on the processed end of the part and rotated.

- Then the parts to be welded are inserted or put on the nozzles and kept in this position until the welded parts soften..

- After that, parts are removed from the nozzles and docked.. In this position, they must be held until the plastic completely hardens.

Tip! Before proceeding with the installation of the structure, you can practice on trimming. This will avoid marriage and save material.

There are cases when it is necessary to make a branch from an already assembled pipeline. In this case, it is necessary to use a special fitting - a welded-in seat for polypropylene pipes, as well as a special nozzle - a semicircular sleeve.

In this case, the work is based on the following algorithm:

- With the help of a special cutter and electric drill a hole is made in the pipe.

- Then the parts are heated and dock in a standard pattern.

That's all the highlights of soldering a polypropylene pipeline.

Conclusion

The main tool for soldering polypropylene pipes is a special soldering iron. Working with this device is not difficult, the main thing is to adhere to certain rules and sequence of actions that we considered above. From the video in this article, you can get more information on this topic.