We use the device for welding of polypropylene pipes

If you do not attach to the manufacturer, then the question of how to choose a machine for welding polypropylene pipes can be answered with one word - professional, this is such a soldering iron, where the presence of a thermostat is provided and the kit includes teflon-coated tips.

But, again, such a tool is quite expensive (much depends on the brand), and even very good masters sometimes get by on standard nozzles, since this does not in any way affect the final result. But we will talk about this in more detail, so that you yourself can make a choice, and also offer you a thematic demonstration of the video in this article.

Welding of polypropylene pipes

Overview of soldering irons and nozzles

Note. Complete with a soldering iron are usually supplied from 3 or more nozzles designed for different sizes of pipes. The minimum set consists of two or three tips for polypropylene 20 mm, 25 mm and 32 mm, but often they are more. Also there are nozzles for pipes with an external section of 16 mm.

- The electric apparatus for soldering polypropylene pipes TEMP PPT-1200 has a periodic heating type, that is, the temperature of the heating, fore part of the unit is controlled by a thermostat, where the maximum heating is 300? C. Power soldering iron 1200W, which is quite suitable for home wiring with an automatic fuse 16A. Nozzles that are supplied complete, ordinary, without Teflon coating.

- The equipment operates on 220V and heats up to the desired limit in about 10 minutes if the ambient temperature is at least 18-22? C. The kit also includes a hex wrench (for fixing nozzles), a screwdriver and 3 nozzles that comes in a metal case.

- The electric unit for welding of polypropylene PROTON PPT-1200 has a periodic type of heating, that is, the temperature of the heating, the bow of the unit is controlled by a thermostat, where the maximum heating is 300? C. Power soldering iron 1200W, which is quite suitable for home wiring with an automatic fuse 16A. The nozzles that are supplied in the kit are regular, without Teflon coating, but their number is increased here to 6 pieces.

- The equipment operates on 220V and heats up to the desired limit in about 10 minutes if the ambient temperature is at least 18-22? C. The kit also includes a hex wrench (for fixing nozzles), a screwdriver and 6 nozzles (20, 25, 32, 40, 63 mm), which is supplied in a metal case.

- Electric soldering apparatus for polypropylene pipes FORTE WP-6318 has a periodic heating type, that is, the temperature of the heating, fore part of the unit is controlled by a thermostat, where the maximum heating is 300? C. The power of the soldering iron is 1800W, which is quite suitable for home wiring with an automatic fuse of 16A. Nozzles that are supplied complete, ordinary, without Teflon coating, the number - 3 pieces.

- The equipment operates on 220V and heats up to the desired limit in about 15 minutes if the ambient temperature is at least 18-22? C. The kit also includes a hex wrench (for fixing nozzles), a screwdriver and 3 nozzles that comes in a metal case. Mass of all equipment 4000g.

- The budget version of the welding machine, this is the BRIGADIER 86-001, which has a periodic heating type, that is, the temperature of the heating, fore part of the unit is controlled by a thermostat, where the maximum heating is 300? C. The power of the soldering iron is only 800W, which is quite suitable for home wiring with an automatic fuse of 16A. Nozzles that are supplied complete, ordinary, without Teflon coating, the number - 3 pieces.

- The equipment operates on 220V and heats up to the desired limit in about 15 minutes if the ambient temperature is at least 18-22? C. The kit also includes a hex wrench (for fixing nozzles), a screwdriver and 3 nozzles (20, 25, 32 mm), which is supplied in a metal case.

- Electrical apparatus for welding pipes made of polypropylene STURM TW-7218 has a periodic type of heating, that is, the temperature of the heating, fore part of the unit is controlled by a thermostat, where the maximum heating is 300? C. The power of the soldering iron is 1800W, which is quite suitable for home wiring with an automatic fuse of 16A. The nozzles that come with the kit have a Teflon coating.

- The equipment operates on 220V and heats up to the desired limit in about 10 minutes if the ambient temperature is at least 18-22? C. The kit also includes a hex wrench screwdriver and 3 nozzles (20, 25, 32 mm), which comes in a metal case. The mass of the kit is only 1100g.

- The nozzle of this type, what you see in the top photo, is made of aluminum alloy and has a high-quality Teflon coating for the working surface, which allows you not to stick polypropylene (PPR) to the surface and not to burn, which is accompanied by smell. Pair tips are used for the polyfusion soldering and are used together with flat types of soldering irons.

- The nozzle of this type that you see on the top photo is made of aluminum alloy and has a high-quality Teflon coating for the working surface, which allows you not to stick polypropylene (PPR) to the surface and not to burn, which is accompanied by smell. Unpaired tips are used for polyfusion soldering and are used together with a soldering iron, in which the rod has the shape of a cylinder.

Soldering work

Regardless of how you use the soldering iron, first of all, you need to prepare the pipes and fittings for work, cleaning them from dust, dirt and grease, and also if they get water, they should be wiped or dried. In addition, you should decide on the type of polypropylene pipe, which can be reinforced (hot) or solid-walled (cold).

Note. As a reinforcing layer can be used aluminum foil or fiberglass and, although the price of the second option is higher, and according to the instructions such PPR should withstand up to 150? C (with foil up to 90? C), there is not much difference from a technological point of view.

The thing is, a heating or hot water system rarely has a carrier with a temperature above 80 ?, and if this happens, then for a short period the pipe does not have time to deform, and the main purpose of reinforcement is precisely this protection.

The main difference between hot pipes is how close the reinforcing layer is to the surface - if close, then polypropylene will be removed during welding, exposing the foil, therefore, the quality of the connection will deteriorate.

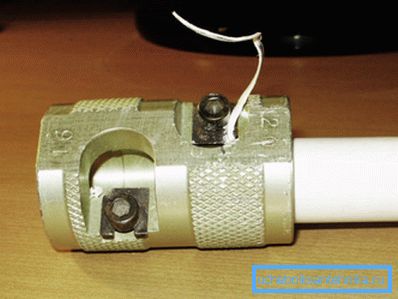

Therefore, the instructions for soldering work recommends removing this layer, but it is extremely inconvenient to do this with a knife, and for this purpose they use a special trimming device for stripping, which is also called a shiver. You simply twist the shiver to the end of the pipe, reducing its outer diameter, at the same time removing the foil and exposing the bottom layer of polypropylene.

Note. Practically all the masters involved in plumbing and heating installation try to avoid PPR with closely spaced foil. Processing the end with a shiver takes a certain amount of time at each joint, all the more so as it is very inconvenient to perform stripping on short pieces, and sometimes it is simply impossible.

So that when docking the fitting solders smoothly, at an angle of 45? and its rotation exactly corresponded to the purpose, it is necessary to make a markup and for this purpose it is enough to put marks on the pipe and fitting with a marker or pencil that should coincide when connecting. In addition, the markup is needed when cutting PPR in length, as well as to indicate the depth at which the pipe will sink into the hot nozzle.

There is a real danger that when soldering, the internal diameter of the joint will be reduced, which will lead to a decrease in the flowability of the water supply system or even to its loss. And this happens because the end goes too deep into the hot nozzle and then, when it is driven into the fitting socket, it also goes further than necessary, but since it is hot, it begins to flatten, creating a congestion.

Therefore, when heating the edge of the pipe, be very careful - its end should go into the hot nozzle by no more than 10-15 mm - so the pipeline continuity will be fully preserved.

On the thermostat of the soldering iron, as a rule, the maximum switch mark is 300? C and this temperature is enough to work even with a slight frost, but this does not mean that this parameter should be a constant mode.

Should be guided by the room temperature of the room - 19-22? C and in such cases, the adjustment knob of the switch should be at around 280? C, well, if you work in the summer and in the heat room, then move the handle to 270? C.

Such modes are most optimal for welding during PPR and a position of 300? C should be used only in a cold room or outdoors, in the cold season, as well as in windy weather.

Now we proceed to welding the pipe with the fitting (they must coincide in diameter) and after preparation and marking of the material we heat the apparatus, which, depending on the model, will dial the required temperature regime from 10 to 15 minutes.

The nozzle should be fixed even before you turn on the soldering iron in the network - it is much more convenient to do it in a cold state, and if you have to work with different pipe diameters (via reduction fittings), you should fix both nozzles at the same time - all brands and types of welding units calculated on it.

If possible, it is most convenient to do the work, sitting on a small stool, stepping on the soldering iron stand with your feet so that the device itself does not move, but this is possible only when assembling individual blocks - in the future such work will have to be done with weight.

So, fit a pipe on one side of the nozzle, and on the other, fit and press them to the desired depth, and then stand in this position for 5-6 seconds so that the polypropylene warms up well. Then you shoot both sides at the same time and without delay, butt them in the desired position, being guided by the labels set in advance, and again maintain for 5-6 seconds in a fixed position.

Installation of water supply is much more convenient to produce individual blocks, which are welded separately, as is seen in the top photo, after which they are soldered into a single system.

Due to the fact that the soldering iron itself is fairly light, on average 1.5-2kg, one person can handle such work by holding the machine in one hand and the welded unit in the other. But for connecting bulky blocks, some experience is needed, therefore, their size should be limited, at least, at first.

Conclusion

In order to cut the polypropylene pipe with their own hands, use special scissors (this can also be done with a hacksaw, but burrs remain after it). The quality of the scissors also has not the last value - a good guillotine makes an even cut, but if it has a backlash or it is bent, then this will not happen (see also the article Polypropylene pipes for plumbing in the house).