Welding equipment for polyethylene pipes - we study all the

Today, various construction equipment has become available to a wide range of buyers. So, now the average consumer can purchase for personal use a set of welding equipment for polypropylene pipes. We will tell you about the use of these devices below.

Types of welding

In order to choose suitable welding equipment for welding polyethylene pipes, it is desirable to have an idea of the working methods. In particular, this procedure can be implemented in two different ways.

Butt joint

This technique is applicable in cases where the diameter of the product is more than 5 cm, and the wall thickness is at least 5 mm. This technology consists in heating the end elements due to the contact with the plate to the state of the required viscosity.

The result is a very reliable fixation, and at the molecular level.

Our instructions will detail the sequence of actions for you:

- Install the ends of the pipes in the appropriate welding machine.

- Place a heating plate between them.

- We press the ends to it, due to the pressure exerted.

- Waiting for the desired level of melting.

- We slightly reduce the pressure and wait for the final heating of the elements.

- Take out the stove.

Note! Do this as smoothly and carefully as possible in order to prevent the destruction of the molecular bond.

- We connect two pipes, due to the same pressure.

- It now remains to wait a certain time (depending on the size) before the structure is assembled.

As you can see, such an operation is a snap, even with your own hands. The main thing is to show maximum diligence and accuracy.

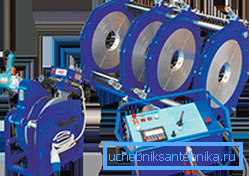

Modern construction stores offer us the following types of equipment for this type of work:

- Automatic welding machine for welding pipes on a mechanical drive. All actions are done manually.

- Hydraulically driven devices. It requires less effort thanks to hydraulics.

- Modern devices on programmed control. These fully automated devices will greatly facilitate, and most importantly accelerate the process. Of course, their price is very high.

We also note the key advantages of the butt technology:

- The human factor is excluded, that is, the assumptions of errors due to inexperience. For this reason, in the end, we have the highest quality connection.

- Process automation (applicable to hydraulic and software samples).

- The possibility of control during the work.

Electrofusion

This technique is mainly used to connect non-pressure pipes for the organization of sewer and drainage complexes. Such welding equipment for polypropylene pipes involves the use of electrofusion fittings.

Interesting: this type of work can be carried out at air temperatures from -10 to +35 degrees Celsius.

The work is performed in the following sequence:

- Prepare a place for manipulation. We make sure in serviceability of devices.

- We select the appropriate fitting.

- We clean the connected part from pollution. It is also desirable to degrease it with a volatile liquid.

- Pipe ends should be trimmed. Remove the oxidized layer, which is often formed during the production process.

- We fix the plastic pipes and fittings in the device (it is called the positioner).

- Protect the connection from dirt and dust with adhesive tape.

- Turn on the device and wait for the completion of the operation.

Checking the seam

After you have turned off the welding soldering iron for polypropylene pipes, you should verify the quality of the work done.

You should visually inspect the seam and pay special attention to such moments:

- The seam should not be located below the surface of the pipe.

- The outer and inner rollers should have a height not exceeding 2.5 mm with a wall thickness of up to 5 mm. If we are talking about more massive samples, then this indicator can be no more than 5 mm.

- The displacement of the pipes should be no more than 1/10 of the wall thickness.

If these three conditions are met, then it can be stated that the work has been carried out correctly and the connection will last for many years.

The most popular devices today

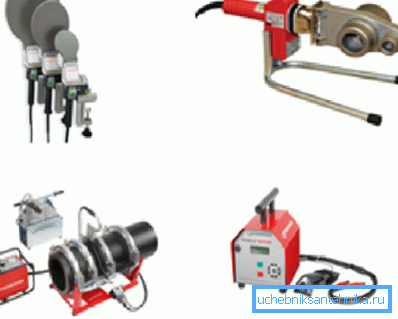

Now consider a few of the samples that are currently popular:

- HE200 is a heating device that allows working with samples with a diameter of up to 20 cm. It has an anti-stick coating that provides high-quality connection.

- R 63 E is an exclusively household appliance that allows working with PP, HDPE and PE pipes with a diameter of not more than 63 mm. It has a display with a temperature controller.

- ROWELD P 355 V - a device for butt welding of products with a diameter of 9 to 35.5 cm. It is used mainly in the field of industry (because of its impressive size.

- ROWELD ROFUSE BASIC is the "home" analogue of the above device. Differs in the highest safety and a possibility of control at any stage of works.

Of course, this is not the whole list. A rich selection of equipment in this area will allow you to choose the right sample for you. Make choices based on your needs, that is, for home use, you should give preference to simple patterns, and for laying massive systems more serious.

In conclusion

At this point we will complete our story, but if you did not manage to comprehend all the subtleties, then do not worry. We have made sure that you get the most complete portion of knowledge. In the presented video in this article you will find additional information on this topic, which will help to understand everything.