Calculation of the profile pipe: mass and bending

How to find out how much the running meter of a square or rectangular pipe? How to calculate the load on the profile pipe of a known size? Let's try to find the simplest answers to these questions.

Why do you need it

Why do you need to know the mass of a meter of a profile product?

There are two main motives.

- In the construction of metal structures, some elements put pressure on others with their own weight along with the payload.. For example, the partition wall in an industrial building puts pressure on the beams, the bridge truss on the columns, and so on. This load must be considered when calculating the strength of structures.

- In addition, rental at metallobaz not sold by the meter, and by weight, and its price is indicated per ton. To recalculate the pogonazh, calculated when creating the project, in the cherished tons, you need to know how much the meter weighs for a particular section and wall thickness.

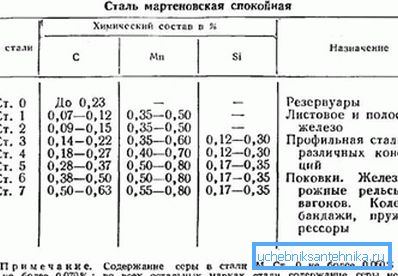

Let's clarify: the exact mass also, of course, depends on the brand; However, the difference between different brands is so small that the current GOST is neglected. The density of steel is taken equal to 7.85 t / m3.

When you need a calculation on the deflection? Let's try to explain with an example.

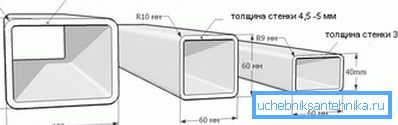

Imagine that you want to build in your cottage a balcony with a frame made of corrugated pipes. Departure of the balcony you know, the estimated load - too. Here, in order to find the optimal cross section of the pipework for the role of carrying beams, you need to know the method for calculating the bending strength.

Weight

The simplest method of calculating is reduced to using the Internet: a calculator for calculating the weight of a profile tube depending on its cross section and wall thickness is easy to find on the websites of many manufacturers and sellers.

However, we will not look for easy ways and will try to find alternative ways to do the calculations with our own hands. Actually, there are two of them.

Regulations

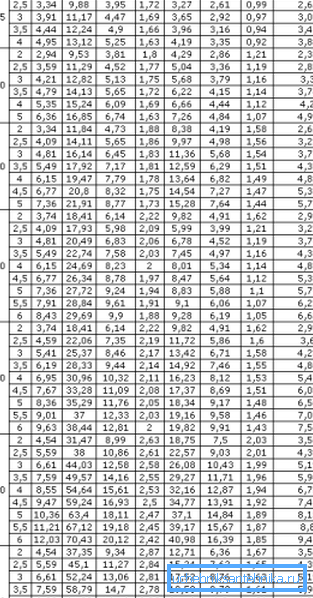

The data we need are contained in national standards:

- GOST 8645-68 contains a range of rectangular steel pipes.

- For a square section, a gauge will be found in GOST 8639-82.

Full tables are too large for a small article, so we will give only some values as an example.

| Side of square tube, mm | Wall thickness mm | Weight per meter, kg |

| 15 | 1.0 | 0.426 |

| 1.5 | 0.605 | |

| 20 | 1.0 | 0.583 |

| 1.5 | 0.841 | |

| 2.0 | 1,075 | |

| 40 | 2.0 | 2.33 |

| 2.5 | 2.85 | |

| 3.0 | 3.36 | |

| 3.5 | 3.85 | |

| 4.0 | 4.30 | |

| 5.0 | 5.16 | |

| 6.0 | 5.92 |

| Side A of a rectangular pipe, mm | Side In a rectangular tube, mm | Wall thickness mm | Weight per meter |

| 25 | 15 | 1.0 | 0.583 |

| 1.5 | 0.841 | ||

| 2.0 | 1.08 | ||

| 2.5 | 1.29 | ||

| thirty | ten | 1.0 | 0.583 |

| 1.5 | 0.841 | ||

| 2.0 | 1.08 | ||

| 2.5 | 1.29 | ||

| 3.0 | 1.48 | ||

| 15 | 1.0 | 0.661 | |

| 1.5 | 0.959 | ||

| 2.0 | 1.23 | ||

| 2.5 | 1.48 | ||

| 3.0 | 1.71 | ||

| 20 | 1.0 | 0.740 | |

| 1.5 | 1.08 | ||

| 2.0 | 1.39 | ||

| 2.5 | 1.68 | ||

| 3.0 | 1.95 |

Please note: we strongly recommend that you read the full text of the documents. As we will find out further, the full version of the tables will be useful in further calculations.

Density calculation

With some error, the calculation of the weight of the profile pipe can be performed without tables of the assortment. It is enough to know all the main dimensions of the product and the density of steel, which, as we have already learned, is assumed to be equal to 7850 kg / m3, or 7.85 g / cm3 in calculations.

Instructions for the calculation will not cause difficulties for any person who remembers the basics of geometry.

- Calculate the surface area of the meter proftruby. It is equal to the product of the perimeter (the sum of all four sides) and the unit.

Attention: in order to get the result in tons without complicated recalculations, it is better to immediately convert the dimensions to meters.

- Multiply the area by the wall thickness and get the volume of the metal in the running meter.

- Multiplying the volume by the density of steel, we get the mass of the meter.

Let us, as an example, perform the calculation for a rectangular section 180x150 with a wall thickness of 12.0 mm.

- The area will be equal (0.15 + 0.15 + 0.18 + 0.18) x 1 = 0.66 m2.

- The volume is 0.66 m2 x 0.012 m = 0.00792 m3.

- Weight - 0.00792х7850 = 62.172 kg.

The result is somewhat different from that prescribed in GOST (55.71 kg) due to the fact that when you unfold a real trade pipe into a flat billet, we will get noticeable thinning where its longitudinal edges were. The error will be smaller, the thinner the wall and the larger the section size.

Flexural strength

How is the strength of a bend tube calculated?

For our case, two formulas are relevant:

- M = F * L, where M is the bending moment, F is the force applied to the profile, measured in kilograms (kgf), and L is the lever arm in centimeters. For example, for the notorious 1 meter wide balcony with three people standing on its edge with a total weight of 250 kg, the bending moment will be equal to 250 kgf x 100 cm = 25000 kgf * cm.

- M / W = R, where R is the strength of the steel grade, and W is the moment of resistance of the section.

Obviously, the parameters R and W are constants that have to be found somewhere. We will try to simplify the task of the reader:

| steel grade | Strength (R), kgf / cm2 |

| St3 | 2100 |

| St4 | 2100 |

| St5 | 2300 |

| 14Г2 | 2900 |

| 15GS | 2900 |

| 10G2S | 2900 |

| 10G2SD | 2900 |

| 15HSND | 2900 |

| 10HSND | 3400 |

The second parameter - the moment of resistance - can be found in the same tables of the assortment in GOST 8645-68 and 8639-82. Thus, for a pipe with a section of 180x150 with a wall thickness of 12 mm along the A axis (along the wider side), it will be 346.0 cm3, and along the B axis - 310.8 cm3.

Let's try to choose a pipe size for our balcony with a load of 250 kg and a departure of 1 meter, based on the following conditions:

- The load falls on only one of the carrying professional pipes (three people are positioned in such a way that their weight is not distributed over the neighboring beams).

- The material used in the manufacture of the supporting frame of the balcony of the pipes - steel St4.

So, let's proceed to the calculations.

- 25,000 kgf * cm / W = 2100 kgf / cm2 / W. The moment of resistance, therefore, should not be less than 25,000 kgf * cm / 2100 kgf / cm2 = 11.9 cm3.

- It now remains only to choose a pipe with the corresponding value of W in the table of the assortment. With a square cross section, this condition is satisfied, in particular, for sizes 50x6 and 60x3.5.

Note: we have found the minimum dimensions at which the beam can withstand the appropriate load; at the same time, they neglected the margin of safety (for example, in case someone from the hypothetical visitors of the balcony jumps up), the own weight of the balcony and the wear of the frame by corrosion. In practice, these factors are leveled at least threefold by the moment of resistance.

Conclusion

We hope that they did not tire the reader with an abundance of dry numbers and calculated tasks. As usual, additional information can be found in the video in this article. Successes!