Cross-section of the pipe and its internal volume:

Today we have a small excursion into the school programs of geometry and physics. We will recall how the cross-sectional area of the pipe and its internal volume are calculated. In addition, we have to figure out how changes in the diameter of the pipeline act on the pressure in the fluid flow. So go.

Calculate the cross-sectional area

Obviously, the formula for the cross-sectional area of a pipe will depend on the shape of this section. What options are possible?

Round

The area of the circle is S = Pi R ^ 2, where:

- S is the desired value;

- Pi is the number of pi, which is usually rounded to 3.14;

- R is the radius of the circle (for a pipe, half of its internal diameter).

As an example, let's calculate the internal cross-sectional area of a round pipe with an internal diameter of 100 millimeters.

- The radius will obviously be 50 mm, or 0.05 meters.

- The area will be equal to 3.14 x 0.05 ^ 2 = 0.00785 m2.

Please note: when calculating the flow rate of gravity flow pipelines (for example, domestic sewage), the actual, not so much, but so-called living section of the flow is limited to the average water level.

Where can I get data on the internal diameter of GVP pipes used in the installation of internal building communications? Sellers usually indicate only the remote control (conditional passage) and the type is light, ordinary or reinforced.

All the necessary information can be found in GOST 3262-75, according to which these products are manufactured.

How can you calculate the actual internal diameter from this table yourself?

The instruction is simple and, in general, obvious.

- Select the appropriate products of interest for you and the type.

- Subtract from the outer diameter twice the thickness of the walls.

Tip: an online calculator of cross-sectional area of any type of pipe can often be found on the manufacturer’s website or dealers.

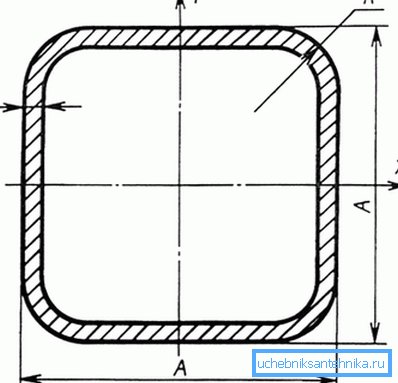

Square

Profile pipes are relatively rarely used for transporting liquids: these are areas of priority use for circular pipes.

Why?

- The circle has a minimum wall length with a maximum area of all geometric shapes.. From here - a practical consequence: with a constant thickness of the walls, a round pipe will have the maximum throughput. Or, in other words, with a fixed carrying capacity, the price per running meter of a round pipe will be minimal.

- By virtue of this same feature, a round pipe has maximum tensile strength.. Pressure is not in vain measured in kilograms per square centimeter: the larger the area of the pipe walls, the greater the force applied to them at a fixed pressure inside the pipeline.

However, in some cases it is necessary to calculate the internal cross section of the proftrub. In the case of a square tube, it is equal to the square of the difference between the outer dimension of the tube and its double thickness of its walls. So, for a product with a size of 100x100 mm with walls 4 mm thick, the calculation will take the form (100 - (4 x 2)) ^ 2 = 8464 mm2.

Note! Most formulas use the area expressed in square meters. The conversion factor of mm2 to m2 is 1: 1,000,000, that is, in the above case, we get 0.008464 m2.

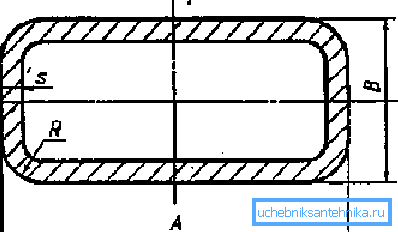

Rectangular

The calculation scheme is almost identical to that described for square pipelines. The only difference is that the walls are not the same; accordingly, we multiply their dimensions minus yes, again, twice the thickness of the walls.

So, for a rectangular tube with a size of 150x180 mm with a wall thickness of 6 mm, the value sought will be (150 - (6 x 2)) x (180 - (6 x 2)) = 23184 mm2, or 0.023184 m2.

Volume

Everything is quite simple here. The volume of a pipe of any type is equal to the product of its length (molding) by the sectional area. In the last example, the internal volume of the 25-meter pipeline will be 0.023184 x 25 = 0.5796 m2.

Cross section and pressure

There lived in the glorious 18th century Swiss Daniel Bernoulli. He lived, he lived and formulated between times the law, which later marked the beginning of modern hydrodynamics and was named after him.

If we translate the dry language of formulas into the Russian we are used to, then it can be formulated as follows: the flow rate is inversely proportional to the static pressure of the liquid or gas in it.

On the practical side, this means that at the transitions of the diameter of the pipeline the flow behaves contrary to common sense: an increase in cross section causes an increase in pressure, while a decrease and the associated acceleration of the movement of a liquid or gas increase.

Nowadays, this effect is widely used in mechanisms of various purposes.

Let us give a couple of the most obvious examples that any of us encountered.

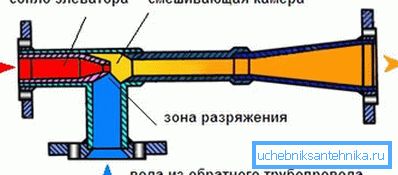

- The main element of the heating unit at home is the elevator. It is a nozzle in which a jet of water with higher temperature and pressure from the supply pipe is injected into a volume filled with cooler water with low pressure from the return. Due to the drop in static pressure in the jet, it draws a portion of the water from the return pipe through the suction designed for this purpose into re-circulation. (See also the article How to bend a profile pipe: features.)

- The airbrush and airbrush use the same effect: the rapid air flow due to the vacuum created in it pulls the dye out of the tank, crushes it, turns it into an aerosol, and deposits it on the surface being painted.

Conclusion

We hope that they did not tire the reader with an abundance of numbers, formulas and calculations. As always, additional materials on the topics studied by us can be found in the video in this article. Successes!