Do-it-yourself asbestos pipe foundation: how to calculate

In many cases, the column foundation is the ideal foundation for the construction of a small house, bath or gazebo. On heaving, freezing soils, the installation of the recessed strip foundation is not expedient and expensive.

But the well-established pillars will withstand any tests, creating a reliable and durable platform for the building. One of the successful options is asbestos pipes for the foundation, which have a lot of positive characteristics.

Varieties of asbestos cement pipes

For the manufacture of standard pipes is 85% of Portland cement, 15% of asbestos and water.

By appointment, they can be divided into two categories.

- Non-pressure analogues. The products are intended for transportation of substances without pressure in the finished system. Such pipes are more often used for ventilation networks and similar communications. Marked letters BNT. (See also the Exhaust Tubes - Features article.)

- Pressure products. The product is much stronger, as it must withstand pressure from 6 to 9 atmospheres. Have a WT label.

Note! As for the cost, the price of pressure pipes is higher, but it is not necessary to choose this type. For the construction of the foundation, pressureless analogues of pipes with a diameter of 150/250 mm are quite suitable. Strength plays a major role here, because the main load will be borne by concrete.

Material advantages

- Cement-filled asbestos pipes form a solid monolithic structure.

- Competently mounted system has a high degree of frost resistance.

- Aggressive media are not afraid of the material.

- The outer surface is smooth and neat.

- Formwork deformations are not observed when pouring concrete mix.

- Distinctive from the ruberoid formwork property is increased rigidity.

Required calculations

For different regions there are their own specific standards of construction.

Depth

The colder the winters and the harsher the climate, the deeper the piles are driven. The main thing is that they enter about 15 cm below the level of soil freezing.

Here is the approximate depth of permafrost for some areas.

- In the most northern regions (from Vorkuta and Salekhard to Novosibirsk), the soil freezes to 220–240 cm.

- In Perm, Chelyabinsk, Yekaterinburg, Orenburg, Ufa, the depth is slightly less - from 180 to 190 cm.

- In Samara and the Urals, the depth is about 160 cm.

- At the level of Moscow, Kostroma, Saratov, Penza and Tver, piles are driven to at least 140–150 cm.

- Kursk, Volgograd, Pskov and Astrakhan are notable for warmer winters. Here, freezing comes to the level of 110-120 cm.

- Even warmer in Rostov, Krasnodar, Nalchik. Piles are driven in 60–80 cm.

Note! It shows the maximum depth of permafrost observed in the coldest and least snowy winters. If there is a permanent snow cover, the pile foundation will not suffer any more, since the soil will be frozen to a lesser depth.

Pipe calculation

Before construction begins, some more calculations should be made. Thus, the aboveground part of the pipe protrudes 30–35 cm above the ground level. But, if frequent flooding is observed, this value is recommended to be increased.

As for the diameter, the standard column foundation of asbestos pipes 25-30 centimeters in diameter is good for a log house. Under the terrace or gazebo fit piles of 10 cm thickness.

Load base

It is clear that the piles must withstand the weight of the structure with a good margin.

Below are brief information about the specific gravity of basic building materials.

- Brick (thousand / piece) - 3500/3700 kg.

- A coniferous forest of varieties round (m3) - 450-750 kg.

- The sawn wood (m3) - 600 kg (coniferous), 850 kg (deciduous).

- Sand (m3) - 1500 - 1650 kg.

- Crushed stone (m3) - 1400/1800 kg.

- Sleepers (pcs.) - 75 kg.

- Insulation (mini wool, felt) - 100–250 kg.

The piles are installed at the corners of the building, at the points of intersection of the supporting walls, and along the perimeter, in increments of a meter.

Construction of the base of asbestos cement pillars

Based on the above factors, the number of pipes required for the work is counted. It is necessary to calculate the approximate mass of the future building, its size and find out the depth of soil freezing in your area. Only after that you can buy materials and start work.

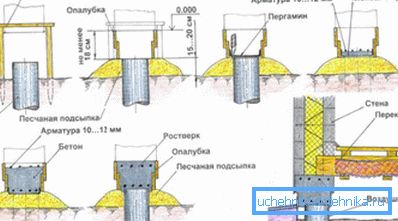

Preparatory work

- Initially, the territory is marked. A trim is installed, then the string is pulled. Pegs are placed at the intersection centers of the twine; they will mark the location of the wells for the piles.

- After installing the pegs, it is recommended to remove the twine. Then nothing will interfere with the drilling of wells.

- Wells are drilled. Instruction advises to use a garden drill, or TISE. If possible, use special equipment, it is worth it.

- The depth of drilling depends on the depth of frost penetration, plus 15–20 cm in reserve. The diameter of the well should coincide with the diameter of the pipe.

- An extension is made at the bottom of the pit. It is convenient to use the drill TISE or bayonet shovel.

- Fragments of pipes of pre-calculated length are cut.

Note! It is recommended to put garbage bags on the lower ends of the pipes, securing them with duct tape. The package should not be taut tight along the bottom, as it will serve as a barrier between the ground and concrete when creating the expansion. It is especially desirable to do this if the groundwater is high, and water appears at the bottom of the well.

- A reinforcing cage is created from four metal rods. The design is connected together by wire. At the bottom of the bar you need to bend the letter L, forming a heel.

- A stud is prepared, an anchor for a post bundle with a bottom strapping. For the pile-mortar base it is not needed, it is enough to bring the reinforcement above the column.

Pipe installation

- An asbestos pipe is installed in the well.

- To create a widening below, a small portion of the concrete solution is poured into the pipe. At the same time, the pipe is slightly raised and lowered so that the mixture fills and the attached bag, forming an expanded end.

- The solution is whipped with a spade or rebar, then the column is pressed tightly, making sure that the fit is as tight as possible to the bottom of the well.

- The first and subsequent pipes are inserted at the same level, controlling the level and stretched with twine. To prevent the column from sinking deeper than the calculated one, a clip is made of two long and one short bars in the shape of a letter P. The ends are tightened with a rope.

- If the piles still stick out at different heights above the ground, they can be cut to the same level at the end of the work.

- A frame made of reinforcement is inserted into the formwork from the pipe. For a columnar foundation with strapping of timber, the frame should stand slightly below the edge of the pipe. Under the pile-rostrum base frame put, leaving the protruding end.

- Concrete is poured in and a stud is inserted. For the maturation of concrete, the top of the pipe is covered with a film.

Conclusion

It is quite possible to make a reliable basis independently, from an inexpensive and durable material. You will save both time and money, and the future home or bath will find a worthy foundation.

You will find more information in the video in this article, where the process is presented clearly.