Do-it-yourself pipe profile products: 5 illustrative

Metal pipe with a rectangular cross section due to its unique properties is a multifunctional building material. From it built a lot of different designs. The most common of these will be discussed in this article.

General provisions

The principal differences between a profile pipe and a conventional pipe are the rectangular shape of the cross section and the presence of stiffeners. These features are the fundamental reasons for its merits. Let's look at them in order to better understand possible applications.

Benefits

- Very high strength. All the pressure is not in the middle of the product, but on the above-mentioned stiffeners, which protects it from deformation.

- Rational geometric shapes. Parallelepipeds are easier and more compactly folded for storage or transportation, unlike cylinders, and also are better combined with flat surfaces and more reliably fasten with each other.

- Relatively low price. The angular shape allows you to save on the material in the manufacturing process.

- Easy operation. The connection of elements can be carried out both with the help of bolts and with the help of welding into the most intricate designs.

Tip: if you use galvanized pipes, it is not recommended to engage in welding parts, as under its influence the zinc layer is broken.

- High resistance to temperature extremes.

Disadvantage

The minus is very conditional, but also worth mentioning is the complexity of bending. What makes the products in question so durable also prevents them from bending. If your project does not need curved lines, then this nuance does not matter at all, but if you, for example, construct arches, you will have to suffer.

Advice: if it is necessary to bend a profile pipe, but there is no special machine at hand, fill the product with sand, seal the edges with wooden sleeves and carry out the design as if it were a regular round pipe. The filler will distribute the pressure evenly and the bend will be realized.

Use cases

The construction of the profile pipe can be very diverse, here are some examples:

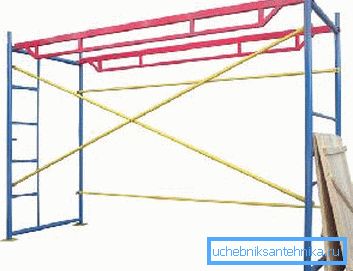

Example 1: scaffolding

If you started construction work above the level of the ground floor window, then you will definitely need scaffolding, which is a convenient and reliable high-rise platform. The considered products perfectly cope with their installation. You will need pipes with the following section sizes:

| Size of the section purpose, mm | Purpose |

| 15 | Spacers |

| thirty | Racks |

| 25 | Connecting inserts |

Assembly instructions look simple:

- Prepare a flat platform.

- Make a drawing.

- Mark up.

- Drill bolt holes.

- Connect all items.

- Top lay wooden shields.

Example 2: stepladder

The stepladder from a profile pipe is done quite simply with its own hands. Its value is difficult to overestimate, especially if you live in a private house. There are a million places that cannot be reached without a suitable staircase.

Tip: if you need a construction with a height of more than three meters, then it is better to get a factory model, which is made using all the necessary technologies and fully meets the requirements of safety rules.

To design you will need:

| Component | Options |

| Pipes with rectangular section |

Wall thickness of at least two millimeters |

| Bolts, nuts and washers | M8? 70 |

| Metal stripes | 3 units with dimensions of 180? 30? 3 mm |

| Hook | 1 unit 60 cm long |

Example 3: Gate

Looking for solid, reliable gates? Pipes with a rectangular section will perfectly act as a frame, it can be sheathed with metal, wood or polycarbonate at your discretion.

The approximate order of work is as follows:

- Drawing sketch.

- Preparation of tools and materials.

- Marking and cutting iron.

- Installation of support pillars.

- Welding profile tubes in the frame.

- Fixing the hinges and installing the structure on the poles.

- Paintwork.

- Applying plating and decor.

Example 4: furniture

You must have met in school chairs and desks from the material in question. Such and similar designs are easy to make yourself. As you can see in the figure, the profiles again act as a steel skeleton, and the installed sheets of chipboard complete the overall look. On the one hand, it is primitive, but cheap, reliable and durable.

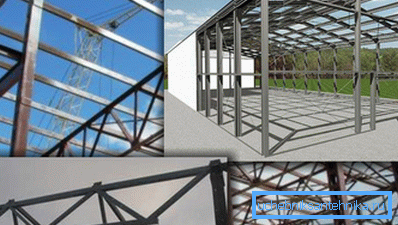

Example 5th: greenhouse

This is ideal for a greenhouse for several reasons:

- High strength will allow to use any material as a plating and withstand all kinds of atmospheric phenomena throughout the year.

- Simplicity of installation will make it possible to cope with the assembly of the whole structure without an invitation from specialists, and the possibility of dismantling - at any time to disassemble and hide the object or move it to a more comfortable place.

- Relative ease does not require a strong foundation.

- Affordable value does not empty the family budget.

- Attractive appearance will decorate, and not disfigure the interior of your site.

It is also worth noting that the profile pipe besides the implementation of greenhouses, is also great for building garden arbors.

Conclusion

The profile pipe due to its special form has extremely high strength, which is the main reason for its widespread use in construction. Let's add here a low cost with ease of operation and get almost perfect building material.

Above, we cited only five examples of the application of such a practical product, but, having shown ingenuity, they can be found much more. The video in this article will introduce you to additional materials. Good luck to your design!