Garage from a profile pipe: installation in 5 steps

A car does not have to constantly spend the night outdoors, especially in our climate zone - every good owner knows this. Garage needed. In this article we will analyze the most rational way of its construction - with the help of shaped pipes.

General provisions

Why it is worth stopping on the choice of metal as a building material for the garage? Perhaps the capital brick building will be much better able to cope with its task? To answer these questions, let's look at the benefits that iron provides us:

Merits

- Affordable price of the project. Professional sheets are much cheaper than reinforced concrete or brick.

- No need for a strong foundation. The ease of the material used makes it possible to get by with less costly base options.

- Ease of installation work and the minimum amount of debris after their completion.

- Sufficient structural strength. Steel "skeleton" ensures the reliability of buildings.

- The possibility of subsequent dismantling to move the building.

disadvantages

There are also negative sides, but they are rather arbitrary:

- The need for additional thermal insulation. But, firstly, taking into account the overall savings, the additional costs of thermal insulation materials will not be so noticeable. Secondly, it is worth warming up any garages in the conditions of our severe winters.

- The possibility of damage by rust. It is prevented by the use of non-corrosive types of metal, processing by special means or painting. Also an important role in reducing dampness is played by high-quality ventilation, which, again, is important for a garage of any material, since the car is still iron.

Construction progress

Instructions for the construction of a metal garage begins with the preparation of its drawing.

Layout

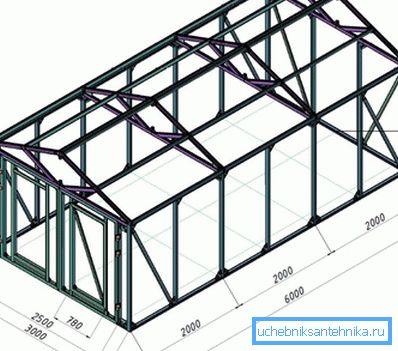

The plan of the cloister of your car does not constitute anything complicated, since, in fact, it is one room, the most common size of which is 6 m by 3 m. But it is better to have it at hand when purchasing materials and when marking the foundation, so that not to make annoying mistakes. (See also the article Greenhouse made of plastic pipes: features.)

Tip: if you plan to install the stove in the garage, then mark its location in the drawing in advance. This will allow you to strengthen the foundation under it, which is required for fire safety.

Base

As we have already noted above, the construction of shaped tubes, due to its relative lightness, does not need a powerful base. The following options are fine:

| Foundation Type Name | Features of installation under the garage of the profile pipes |

| Monolithic | This is the most reliable and expensive type of foundation, which is a solid reinforced concrete slab over the entire area of the future building. In our project, it will suffice to have a tie with a thickness of ten centimeters, which will simultaneously fulfill the role of the floor. |

| Tape | To save money, a shallow-depth version of this type of foundation, which is the concreting of the perimeter of the building to a depth of a couple of tens of centimeters, is quite suitable for a garage. |

| Pile | The cheapest method of creating a solid foundation, as it involves pouring concrete, laying bricks or installing pipes only at the highest load points. |

Tip: if you are planning to fill a monolithic foundation, then it is recommended to immediately take care of arranging the pit along its center. This will make it easier for you in the future to repair your car.

Frame

Assembling the frame is easy, but still requires some special tools and the ability to use them:

| Tool name | Purpose |

| Welding machine | Welding is the most rational and reliable method of joining profile pipes into a single building core. |

| "Bulgarian" or hacksaw | During the installation work you will need to adjust the size of the iron products. |

| Drill | To create holes that allow metal sheets to be attached to bolted joints |

| Shovel | Dig a trench for the foundation |

| Screwdriver or screwdriver | Screw in bolts |

Tip: if you do not plan to rearrange or move the garage in the future, then you can also use welding to fix the trim. From this structure will turn out even stronger.

From the materials you will need:

- Profile pipes with a cross section of 40 mm by 40 mm.

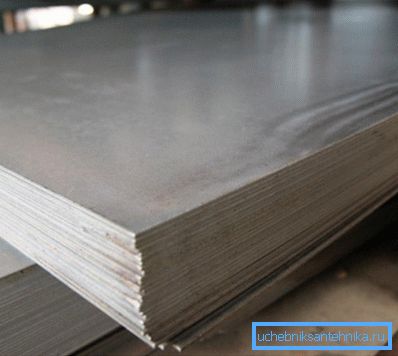

- Metal sheets 3 mm thick.

- Bolts, nuts and lock washers.

- Primer or other water repellent for the treatment of joints.

The number of all necessary components is determined depending on your layout.

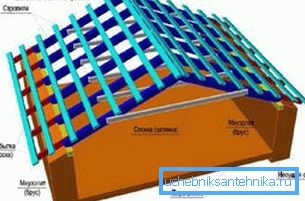

Roof

The best choice would be the installation of a gable roof, which will reliably protect against precipitation, wind and heat losses. To do this, also by means of welding, truss beams are installed from shaped pipes, and solid sheets of iron with a twenty-centimeter overhang behind the walls are laid on top. This design is both aesthetic and practical.

Ventilation

In order for the dampness not to harm your car, you must have a competent arrangement of the ventilation system.

For this:

- In one corner at a height of 20 cm we mount the supply pipe.

- In the other - at a distance of 20 cm from the ceiling exhaust so that its other end towers above the roof.

- On the hood install fan with a motor to enhance the air flow.

Conclusion

Garage needed for the car. One of the most rational and practical ways of arranging it is an assembly of shaped pipes. Installation of this design is easy to implement, and it turns out reliable and inexpensive. (See also the article Feeder for chickens from the sewer pipe: features.)

The video in this article will provide you with additional material.

Take care of a suitable home for your car!