Gazebo from the profile pipe: construction using the

In this article we will talk about how to build a gazebo from a shaped pipe with your own hands. In addition, we consider the features of the selection of building material. So, first of all we will decide on what we will build from.

Choosing a building material

Today, it’s not particularly difficult to pick up a suitable drawing for a gazebo from a profile pipe, where it is more difficult to choose building materials that will not lose their original appearance and performance during long-term outdoor use.

Profile pipes are considered the best solution for the construction of summer houses.

The choice of such material is not accidental, since it has the following advantages:

- stiffness due to the rectangular or square cross-sectional shape;

- corrosion resistance in case of proper pre-operational preparation;

- affordable price, in comparison with other building materials;

- ease of machining and, as a result, short deadlines for installation;

- possibility of making arbors with a configuration of varying complexity.

The profile pipe from which we will build an arbor is a type of hollow metal-roll with a rectangular cross-sectional shape. (See also the article Garage of the profile pipe: features.)

As a rule, this type of metal-roll is manufactured using low-alloy carbon steels of 09G2S or St3SP type. More rarely, profile pipes are made using stainless steel.

Important: Stainless steel is an excellent material, as it does not face corrosion, but the price of a stainless steel frame for an arbor will be high. In addition, the metal from stainless steel is an order of magnitude more difficult to process compared to ordinary steel.

The profile tube is made by cold or hot forming from a billet with a round section. The finished product is subject to mandatory tests in order to identify possible violations of the integrity of the longitudinal seam. That is why you can not doubt that your gazebo will be resistant to mechanical loads.

Select the configuration of the structure

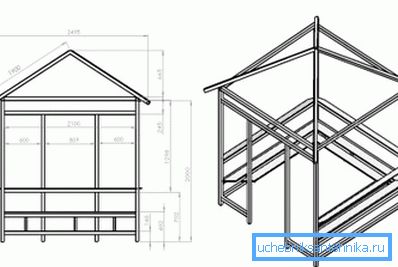

If you are wondering how to make an arbor out of a shaped tube for the first time, then it is better to choose a simple structure without any complicated decorations. Let it be the lower and upper trim, connected by several vertical posts, and a gable polycarbonate roof.

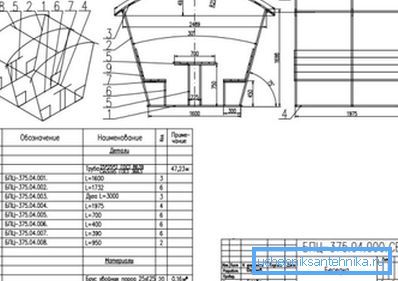

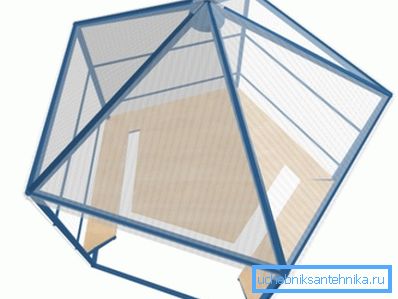

If you have the skills to work with metal, you can choose the option more interesting and try to make the proposed further drawing into reality.

This design is made with the lower and upper strapping in the form of a pentagon, and the upper strapping for a special aesthetic effect can be made wider than the lower.

Perhaps the most original and at the same time simple version of the frame in execution is a structure with a rounded roof. The design is successful, since it will be easy to cover one large sheet of polycarbonate and equip with wooden benches.

Tools and consumables

Installation of shaped pipes can be carried out in two ways:

- by bolting;

- through welds.

What to choose when building a gazebo on the garden?

If there is an impressive experience and an inverter welding machine with all related accessories, then welding is the best option. If there is no experience in welding and the corresponding equipment, it is advisable to use a bolted joint. (See also the article Butt-Weld Pipe: Features.)

In this and in another case, such tools as:

- LBM (Bulgarian);

- electric drill with screwdriver function and drill set;

- clamps;

- measuring equipment, including tape and level.

In addition to the pipes from which the framework will be assembled, you will need sheet polycarbonate, self-tapping screws for its installation, as well as paints and varnishes and tools for their application.

Getting Started

The assembly instructions for the frame are not difficult; the main thing is to act in stages:

- We mark on pipes the size on which cutting will be carried out;

- We insert a disk for metal cutting into the grinder and cut the pipes into pieces of the required size.

- We start the assembly from the bottom trim and first we clean the metal in the areas of the intended compound until there is no rust.

- Then we connect the elements of the lower strapping with clamps and cook the joints.

- On the corner joints we weld the vertical supports.

Important: When welding the supports, the vertical positioning is determined by the square relative to the bottom trim, and not by the water level, since the site where the installation is performed may be uneven.

- At the next stage, the upper strapping is boiled; the process is practically the same as the lower strapping assembly.

- Next, the guides are rolled, to which we will fasten sheet polycarbonate.

- After the main structure is assembled, the guides are welded for mounting the wooden benches. For the manufacture of such brackets easier to use not a profile tube, and a metal corner.

- At the next stage, using an electric drill, we drill holes in the guides on which the benches will be mounted.

- After that, go with a drill to the future roof. In the profile pipe, at a distance of 10 cm from each other, we drill holes for screws, which in turn will fasten polycarbonate sheets.

- At the next stage, the entire metal structure is thoroughly cleaned with a drill with a wire brush attachment from rust.

- We paint the cleaned and dust-free metal in several layers with enamel PF 115 or 116.

- Upon completion of the painting work, you can proceed to the installation of the roof and the installation of benches.

Conclusion

Using high-quality and at the same time simple in terms of implementation drawings of arbors from a profile pipe, you can easily cope with the installation work.

Do you have questions requiring explanatory comments? More useful information you can find by watching the video in this article.