Greenhouse from pipes: available options and features of the

Today it is difficult to imagine a summer cottage without a greenhouse, which is first used for growing seedlings, and then for forcing cucumbers or tomatoes. Make it of different materials, including from a p / e film and wood. In our case, we will consider a more attractive option - how a greenhouse is mounted from pipes.

The first question that the summer resident puts before himself, who decided to make a greenhouse, what is the best way to make it? We will move to the background the options of plastic, and dwell on the more serious ones. Below we will look at how a greenhouse is made from metal pipes with our own hands.

About the material

The galvanized profile tube for greenhouses makes it possible to create sufficiently strong frames. Thanks to the protective coating, the structures are also durable.

It will not be difficult to build an independent framework even for those who have never dealt with such material before. At the same time, there are elements that can create difficulties.

In this case, the main role is played by knowledge of the characteristics of the material, and not the ability to work with it with your own hands. We will talk about this below, at the same time telling that not all advice should be trusted.

If we systematize the answers we received from friends or in the global network, it all comes down to how to build a greenhouse from a conventional round pipe correctly and quickly. And there are very few tips on how to make it from a profile, the section of which is completely different from it, since it is square or rectangular.

It is possible to compare it in construction terminology with a bar, but not as with a round timber. It has four stiffeners, which distinguishes the material from a conventional pipe. Because of this, with less weight, it is significantly stronger than standard products.

When bending, the main load will fall on its edges, but the central part practically does not feel it and therefore is not deformed. Due to the characteristics of the profile pipe - the best strength and low weight of relatively round options, the designers successfully use it in their projects.

How to bend

When greenhouses are made of galvanized pipes, it is not always possible to bypass this issue. Therefore, a special approach and special tools are required. This is especially true of core products, when many difficulties begin to arise even at the stage of creating its drawings.

In contrast to the usual, it may require difficult devices that can be located only in specialized companies or metalworking shops.

Bending a profile pipe without them at a certain angle may result in damage to it. As a result, the cost of construction will begin to increase markedly.

Therefore, before starting the process, assess your capabilities. Think maybe a greenhouse made of polypropylene pipes with your own hands is your option?

Process

Below is given the instruction that will help to cope with this work without the use of outside help. And everything will be possible at home.

| Option I - welding |

|

| Option II - sand | In this case, you do not need welding work. Only clean river sand will be needed, in which clay and earth as impurities should be very small. Therefore, before embarking on the main work, it must be prepared - cleaned and sifted.

|

Tip: the steeper the bend of the product should be, the more often marks should be put on the marker, and vice versa.

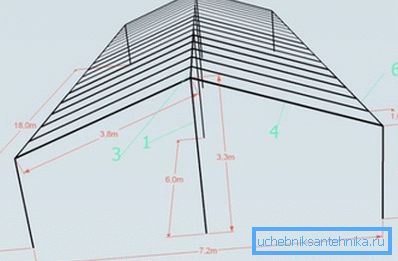

Making a drawing

So, all doubts were left in the past, and you decided to make a greenhouse from a shaped tube. When drawing up his plan, try to reduce as many as possible the number of bent elements. So you will save not only time, but also money.

Let's also not forget about the welding work that may be needed during the work process. If you do not have such equipment, or you simply have nowhere to go for help, make sure that you do not need them when organizing the framework.

Advice: set yourself a goal to mount only with fasteners. Especially since the profile tube favors this.

The durability of buildings

But all your work may be in vain if the details of the frame will not have external protection from aggressive environmental influences. After a year from the former construction there will be only a rusty skeleton, which is unlikely to stand until next season.

And the industry is ready to come to the rescue of summer residents by offering a selection of various protective equipment in a wide range. So you can significantly increase the service life of the frame, protecting it from moisture and heat, which is the basis of the inner space of the greenhouse.

Conclusion

This article intentionally did not consider how to install greenhouses from shaped pipes, as each manufacturer makes it special. We have touched the main steps of the building, without which it will not be able to fulfill its functional purpose.

The video in this article will help you find additional information on this topic.