Homemade sleds for a snowmobile made of plastic pipes: 10

Polymer pipes are a versatile material that is perfect for arranging water supply, sewage and heating systems in a house or apartment. However, in the hands of a home craftsman who has a remarkable imagination and an irrepressible desire to do something on his own, PVC parts can turn into rather intricate, but no less useful products. For example, in a sleigh for a snowmobile made of plastic pipes, the manufacturing process of which will be discussed below.

Varieties of sled trailers

It should be noted that you will not find a universal model.

The sledge you need to use is influenced by many factors:

- the specificity of the route to be overcome;

- height and density of snow cover;

- terrain features and so on.

Consider a few of the most common types.

Freight

The design of these sleds is quite complicated. Skis are used for sliding, which can be connected to the frame with shock absorbers. There are varieties designed to transport heavy and oversized cargo.

Sometimes a special box is placed on the cargo sleigh, with which you can go on long tourist trips.

The main advantage of the cargo sleigh is a large carrying capacity and excellent maneuverability. These parameters depend on the size of the frame (the wider, the more stable the sleigh) and the area of the sliding surface (the type of runners used).

It is also desirable that the platform is located high on the snow nast. So the load was protected from getting wet. But do not make the sleds too high, otherwise they will often tip over when cornering.

Volokushi

A very common type of sleigh. Their design is extremely simple. They are sold in all specialized tourist shops and are relatively inexpensive.

Volokushi have one major drawback - because of their characteristics, they often damage the front edge and hitch.

But the advantages are evident:

- little weight;

- low center of gravity;

- fast loading and unloading of luggage;

- lack of frostbite housing;

- the ability to transport a small cargo by water.

Volokushi are absolutely not designed to transport people. The entire surface of the body is in contact with snow, and therefore it is not possible to install shock absorbers. In addition, unlike the models with skis, these sleighs perceive the impact of stones, snow drifts and irregularities throughout the hull, which undoubtedly affects comfort.

Passenger

Few are common in our country due to the lack of appropriate infrastructure (equipped snow trails and parking places). Often these sleds are made by lovers of winter fishing themselves.

They are a plastic or plywood case mounted on skids. The cabin can be equipped with a heater and lighting devices.

The disadvantage is a lot of weight, because for transportation you need to use powerful snowmobiles equipped with a four-stroke powertrain.

The design features of the sled

Before starting construction work, it is necessary to figure out what basic elements the sledges consist of. The fact is that the manufacturing process includes several stages, at each of which there is a knotted part.

It is necessary that you understand the purpose of each of them:

- The main part of any sleigh is the frame, which is the basic support element for the whole structure. It should be as durable as it depends on it:

- safety operation of homemade sleds;

- the duration of trouble-free operation;

- the reliability of the device as a whole.

Considering that the sleigh for a snowmobile will be used in difficult conditions, the frame must be well tolerated by negative ambient temperatures, as well as blows, which the sleigh is constantly subjected to while driving through a forest or shrub.

Otherwise, you will be unpleasantly surprised when the loaded sleighs fall apart during the ride and dump all your belongings on the snow in the middle of a forest clearing.

- The second important element is the runners. Sturdiness is also very important here, however, another important detail is ease of operation. Depends on this whether the sleigh will tip over when cornering or not.

The last point - the size of the structure. This parameter is selected individually based on the tasks to be solved with its help.

Sleds can be small, but maneuverable and light. Or it will be a solid, robust design designed to carry significant loads. You decide.

Sled making

Tools and materials

Once you have decided on the size, you can begin to work.

In order to make sleds for PVC snowmobiles, you will need the following tools and materials:

- polymer pipes for sledges (they are purchased in the store, but you can also use old ones left over from the repair or dismantling of a used plumbing system);

- hacksaw or special scissors for cutting plastic pipes;

- apparatus for welding pipes and fittings;

- industrial hair dryer, with which will be heated, and bend plastic pipes;

- sharp metalwork knife;

- sanding paper files;

- marker for marking parts;

- bolts and nuts for fastening parts;

- metal corners, which will strengthen the key points of the assembly.

Operating procedure

It is easy to make sledges from plastic pipes with your own hands. The price of the material is low, which will save a significant amount of money that you would have spent by purchasing ready-made models sold in specialized stores.

The instructions for manufacturing consists of several successive steps:

- The first thing to do is to apply the lines to the pipes that will be used to cut them.. It is necessary to pay special attention to the careful observance of sizes, otherwise the sleds will be left asymmetrical, and the work will need to be redone. Pipe ends should be fused or joined using fittings. If you are not going to do this, you can cut the ends of the parts at an angle of 45 degrees and fasten the frame with metal corners.

- Given that the sleigh is usually rectangular, the frame will need two long and two short parts.. After marking and cutting, the ends must be carefully cleaned with an emery paper or file.

- After that, the frame is put on a workbench or floor and once again checked for compliance with the design dimensions.. Then its welding is carried out. If you do not have a special soldering iron, ironing can be done using bolts and nuts. To give strength in this case, metal corners are used.

Tip! Use of the welding machine is preferable. With it, you get a stronger connection, and the time to work will take less. If you do not want to buy a specialized tool, you can rent it at a specialized hardware store.

- To give strength to the frame (especially when you are making a cargo sleigh), it needs to be strengthened with additional crossbeams.. To this end, you need to cut several pieces of pipes of suitable length and process their ends with a file, giving an oval shape corresponding to the diameter of the pipe. Further, they are inserted into the frame in the form of spacers and fused or fixed with metal corners. Remember, the quality and thoroughness of the frame assembly will depend on the strength of the sled.

- The next stage - the manufacture of racks. The height of the sleigh above the snow level will depend on their length. It is advisable to take into account the following nuances:

- too high sleds will often roll over when cornering due to a high center of gravity;

- a platform on low racks will be bad for passing through deep snow, and the cargo located on it will get wet.

Tip! The optimal height of the sleigh is from 20 to 30 cm. It is this length that the stands connecting the frame with the runners should be.

- The number of supports depends on the length of the sleigh, but for durability and reliability they need to be done more.. It is desirable that 6-8 pieces be mounted on each side. They should also be processed with a file (of circular cross section) for a more snug fit to the frame. In the process of work, constantly try on the part to the place of its welding. The bottom of the racks may be different:

- flat - if you plan to use flat wide runners (for example, from cut polymer pipes of large size);

- semi-circular - if the runners of the sleigh are round (from ordinary plastic parts of small diameter).

- At the end of the fit, the sizes of the posts of the runners are attached to the frame with a soldering iron or corners. Make sure that all of them were set smoothly, without distortions.

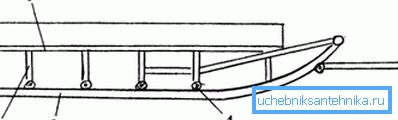

- Now came the turn of the runners. To do this, determine their form. The easiest way to make round skis from ordinary pipes. However, this option is less comfortable in operation, since the sled will often fall through the snow crust and turn poorly.

Self-made sleds from plastic pipes with flat skis are more stable and maneuverable. When cornering at a high speed, the snowmobile will not tip over to the side.

- To make flat skis from round tubes, they must be cut lengthwise and straightened.. For this use a building dryer. In extreme cases, the part can also be heated over an open fire, but this should be done carefully, as the plastic can melt. Warming up the pipe with a hair dryer, on top of it you need to put a board with a load and leave it to cool completely. The front bend is made in the same way.

- In order for the sleds to pass through deep snow, the bend of the skis needs to be made large and the upper end attached to the frame, forming a semicircle. On top of the frame can be installed seat, box for the transport of things and other accessories of your choice.

Do not forget to attach the drawbar, with which the sled will be mounted on the trailer device snowmobile.

Tip! It is recommended to assemble and install a simple electrical circuit with a light bulb, which is mounted on the dashboard. When the sled is removed from the trailer hitch, the chain will open, which will be signaled by the lit light. So, you will not lose the sleigh while riding in the woods.

Conclusion

In addition to the snowmobile trailer, children’s sledges can be made in the same way. It is only necessary to choose the right size. For more information, see the video in this article.