How greenhouses are made from shaped pipes - manufacturing

To ensure a good harvest in conditions of risky farming, it is necessary to use a greenhouse. Of course, it is expensive for many to purchase a finished structure of this kind, however, the way out of this situation is home-made greenhouses from a shaped tube, which are quite easy to make and at the same time have good strength.

From this article you can familiarize yourself with the construction process of such a structure.

General information

What is a greenhouse, every gardener knows - this is a room with transparent walls and a ceiling that protects the growing crops from the negative effects of the environment. But, most importantly - the greenhouse keeps the heat, hence the name (see also the article What is a galvanized pipe for water supply and heating).

Having information about its design, it is not difficult to carry out the drawing of the frame, which is perhaps the main element of the product. After the frame is ready, it will only be covered with a film or sheathed with polycarbonate, which is a fairly simple procedure.

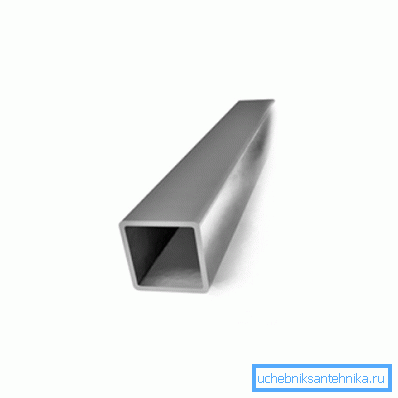

As mentioned above, the most suitable material is a shaped tube, since it has good strength and its price is quite affordable.

In addition, the following advantages of such a solution can be highlighted:

- The steel profile does not bend due to square section;

- Installation of the structure is easy to do it yourself;

- The product is resistant to loads from precipitation.

- The frame is relatively light and elegant.

- Resistance to decay and fungal damage.

- Resistance to temperature extremes.

Tip! It is best to perform greenhouses from galvanized profile pipes, as they are much less susceptible to corrosion.

The only thing for the manufacture of metal frame, you must have the skills to work with the welding machine.

Greenhouse structures

So, any greenhouse consists of three elements:

- Foundation;

- Frame;

- Coverage.

Now let's take a closer look at the features and possible options for each element.

Frame

The strength and durability of the greenhouse depends on the strength of this element. Therefore, the manufacture of the frame must be given special attention.

The most common are the following types of frames:

- Gable;

- Single-pitch;

- Arched.

It should be noted that arched structures have the largest usable area, however, an arched greenhouse is made of a profile pipe with its own hands more difficult than other types of structures, since pipes for the roof of a frame need to be filled with sand and curved, which is not a special tool. In addition, the ideal geometry will not work.

Therefore, the best option would be to make a greenhouse from polycarbonate and a profile pipe with a gable roof. This design allows you to grow plants of different heights, in addition, it provides a good flow of light and allows you to install vents.

By way of mounting the frame of the greenhouse can be:

- Incomplete;

- Folding.

The second option is good if the greenhouse is used from time to time. Therefore, before you create a product project, you should consider in advance what the greenhouse needs to meet, which will allow you to choose the most suitable type of structure.

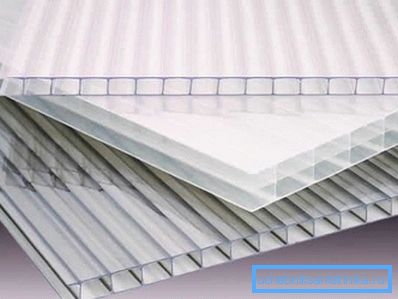

Coating

The coating is a surface layer of the greenhouse, which can be made of different materials.

Most often for these purposes use:

- Glass;

- Cellular polycarbonate;

- Special film.

As well as the material for the frame, different types of coatings have their own advantages and disadvantages.

Therefore, when choosing, one should pay attention to the following points:

- Strength;

- Durability;

- Cost;

- The ability to obstruct cold air and retain heat;

- The ability to transmit sunlight.

Recently, the most popular cellular polycarbonate. Of course, this material is somewhat more expensive than, for example, a film, but it is more durable and better in all other performance characteristics.

Foundation

The foundation is the part of the structure that takes on the load from the entire building and transfers it to the base.

It is usually made from the following materials:

- Tree;

- Bricks;

- Concrete;

- Stone

The type of foundation depends on the type of construction, if, for example, the greenhouse is small and temporary, then it does not need a solid foundation. If you build a solid construction of large dimensions, then it can even be completed with a monolithic strip foundation, which is poured to a depth below the level of soil freezing.

Greenhouse construction

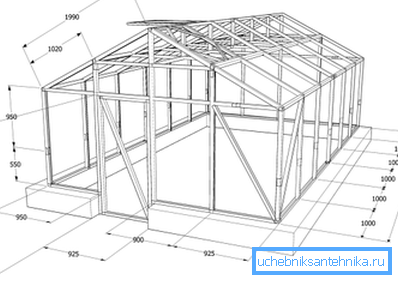

Preparation of drawings

Before you make a greenhouse from a shaped tube, you should prepare the drawings. As mentioned above, it is first necessary to determine the type of structure and its dimensions.

Tip: It is not necessary to create a project completely independently, since you can find ready-made greenhouse drawings from a profile pipe on our construction portal.

Location selection

After all the nuances of the future design will be determined and put on paper, it is necessary to choose a place for the greenhouse. The first thing you need to pay attention to the illumination area during the day. Greenhouses do not build near tall trees, which give a lot of shade.

Tip! The increased air temperature in the greenhouse can be compensated by the ventilation system, which must be equipped with a greenhouse.

If the greenhouse will function in winter, it is better to install it near a residential house, which will reduce heating costs, since it will be possible to use one unit for heating and supplying heat carrier to the house and the greenhouse.

Material

For the manufacture of greenhouses will need the following materials:

| Profile pipes with a section of 40x20 mm | For frame frames. |

| Profile pipes with a section of 20х20 mm | Suitable for bundles between frames. |

| Coating | Film or polycarbonate. |

| Cement and sand | To fill the foundation. |

Note! The framework for greenhouses should be calculated for a length of 6.05 m, since it is precisely such a length that the pipes are realized from the warehouse.

Foundation

Production of the greenhouse begins with the foundation. There can be a lot of options, since for this you can use any suitable material. Next, we consider a simple and common option - a shallow concrete foundation, the depth of one shovel bayonet.

So, the construction is as follows:

- First of all, the ground on which the greenhouse will be installed is leveled.

- Further the trench is dug out by depth and width in a bayonet of a shovel.

- Then an anchor is laid along the trench to which the profile pipes will be fixed.

- After installing the anchors, the trench is poured with concrete.

After completion of this work, construction must be stopped until the concrete completely hardens. It usually takes 28 days.

Frame Mounting

Now that the base is ready, we will consider how to weld a greenhouse with metal shaped tubes. It is necessary to begin work with cutting parts, in accordance with the drawing, so that further work consists only in assembly. For convenience, the segments need to be numbered.

The installation instructions for the structure are as follows:

- First of all, a pipe with a section of 40x20 mm is welded to embedded parts.

- In order to prevent frame distortions, the assembly of the main assemblies should be carried out on a dense and smooth platform.

- Next to the base are welded vertical posts, the position of which must be checked by a vertical level. For an exact match with the vertical, the racks are fixed with slanted corners, which are welded to the horizontal pipe of the foundation. If the frame is sheathed with polycarbonate, the pitch of the racks is selected in accordance with the width of the sheet.

- All racks should be connected with pipes with a diameter of 40x20 mm, which should be placed horizontally, parallel to the base pipes.

- To give the frame greater strength, the rack must be additionally fastened with crossbars.

- An important supporting part is the end frame. It is necessary to perform a doorway and an opening for the vents. For the doorway, you need to use a pipe with a section of 40x20 mm, the vent window is made of a pipe with a section of 20x20 mm.

Segments of openings need to be boiled flush with the main frame. Thanks to this connection, it will be possible to cover the structure with an even layer of polycarbonate, without wrinkles and irregularities.

- The final stage of the frame installation is the installation of the truss system. As a rule, the triangles are welded on the ground, and then fixed on the frame. If the greenhouse is small, then the roof frame can be completely completed on the ground, after which it can be installed on the main frame of the structure and welded.

This is the main part of the work. It remains to perform the door frames and window leaves, then attach them to the posts' openings using canopies.

Sheathing

Fastening of sheets of polycarbonate is carried out by self-tapping screws with a thermal washer. The sheets are attached end to end, and then the joints are coated with silicone sealant.

After complete trimming of the product, the profile of the metal tile should be attached to the roof ridge. At last, polycarbonate sheathes the door frame and vents.

Tip! Since the arched greenhouses of the shaped tube do not have a ridge, polycarbonate sheets in such structures are laid across the roof and fixed on the arcs, taking their shape.

In this manufacture of the greenhouse is completed. It remains only to fertilize the soil, after which you can start planting crops.

Conclusion

Having the skill of working with such a tool as a Bulgarian and a welding machine, it is not difficult to build a greenhouse by yourself. Of course, this will have to spend some time, but then, the construction of a greenhouse from a shaped pipe will turn out to be reliable and durable, able to last for many years (see also the article Metal Clamps for Pipe - Types and Applications).

From the video in this article, you can get more information on this topic.