How to calculate the chimney: technical features

The efficiency of a heating boiler in boiler rooms, as is well known, depends on thrust. In turn, the level of barometric pressure, the outside air temperature, the temperature of the combustion products, as well as the parameters of the flue gas pipe, the dimensions of which are carried out with particular accuracy, affect the force of the thrust. In this article, we briefly consider the method of how the calculation of the chimney is performed with natural draft.

General information

Smoke pipes are built from a variety of materials, it can be:

- Brick;

- Fiberglass;

- Reinforced concrete and so forth

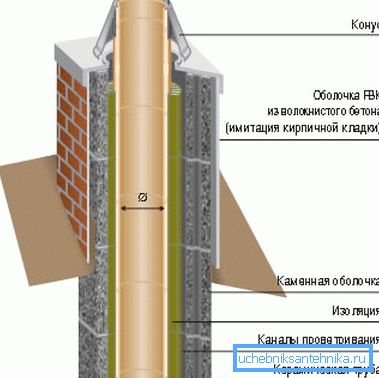

In particular, modular structures made of stainless steel, which are assembled from separate parts, as a designer, have become popular in recent times. They are quite strong and durable, at the same time, the price of materials is quite acceptable. However, regardless of the material of construction, its installation is carried out only after the preparation of the project, made on the basis of a number of multi-stage calculations.

The project is very important, for example, with an insufficient chimney height, the draft in the system may be too weak to maintain the combustion process in the combustion chamber of the boiler. To eliminate this defect, it is necessary to install smoke exhausters that provide artificial traction, which leads to additional costs.

In addition, an important parameter of the chimney is environmental friendliness - the removal of gases into the atmosphere and their further dispersion should be carried out at a height exceeding all buildings in the area.

The calculation of the chimney involves the determination of several parameters:

- Aerodynamic data;

- Determination of height;

- Strength calculation.

Next, we will review the features of all these calculations.

Chimney calculation

Aerodynamic calculation

This part of the design allows you to know the throughput of the structure. This parameter should ensure trouble-free removal of combustion products when the boiler house is operating at full capacity.

Incorrectly calculated chimney capacity can cause smoke to accumulate in the boiler or tract. Therefore, engineering calculations of the diameter of the future structure are carried out by specialists who have the appropriate specialized education.

Features determine the height of the pipe

As mentioned above, when designing a smoke exhaust structure, it is necessary to justify its size from an environmental point of view. This should take into account the calculation of the dispersion of harmful substances in the environment, which are formed during the combustion of fuel.

It should also be noted that the calculation of the height of the chimney of the boiler room must comply with sanitary standards that apply to commercial and factory enterprises. Moreover, the background concentration of hazardous elements in the atmosphere, which was obtained as a result of the functioning of other pollution sources, must be taken into account.

In addition, the height of the structure depends on a number of other factors, such as:

- Meteorological mode of the atmosphere at the site of the boiler;

- Exhaust gas temperature;

- Average air velocity;

- Thermal calculation;

- Aerodynamic calculation;

- Terrain, etc.

Note! Based on the allowable amount of emissions of pollution, is determined and the optimum height of the structure. Due to the fact that in most densely populated areas the situation is unfavorable, most often the structure is erected above the calculated data, which correspond to the lowest possible level. As for sparsely populated settlements, when determining the height of the chimney, they are guided by the height of the buildings of other boiler houses.

Thus, at this design stage, not only the height of the structure, but also the maximum allowable amount of emissions into the atmosphere is determined.

Thermal calculation

Thermal calculation is performed to determine the following parameters:

- Temperature expansion of the material from which the structure will be built;

- Maximum temperature of the outer casing of the structure;

- Type and required thickness of the insulating material.

Strength and stability

So, in the first place affects the traction:

- The diameter of the structure;

- Construction height;

- The amount of fuel burned in the boiler room.

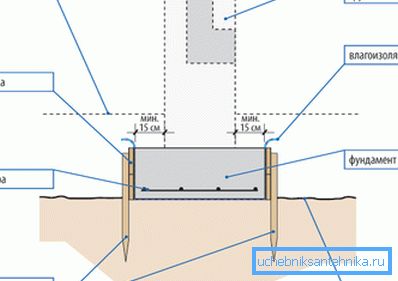

The dimensions of the structure depend on all these parameters, on which, in turn, its foundation depends.

However, in addition to size, to calculate the stability of the structure, the following factors are taken into account:

- Soil behavior;

- Seismic activity;

- Snow and wind loads.

Based on all these data, determine the following parameters of the foundation:

- Its design;

- Sole area;

- Depth of laying, etc.

In addition, the strength characteristics allow not only to perform the calculation of the foundation, but also to determine the most optimal shape and design of the trunk.

Calculation of domestic chimney

To determine the parameters of the chimney of a household boiler house with your own hands, there is no need to perform serious engineering calculations. To do this, you can use a simplified method.

Note! To perform a similar calculation, it is necessary to know the boiler power, i.e. the maximum amount of fuel that can burn in it in an hour. This parameter is contained in the passport to the equipment.

The fact is that all indicators of household structures are about the same:

| Gas velocity in the pipe | At least 2 meters per second |

| Construction height according to SNiP | Not less than 5 meters from the grate |

| Natural gas pressure per meter | Not less than 4 Pa |

| Inlet gas temperature | 150-200 degrees Celsius |

When performing a design calculation, it is necessary to take into account that the thrust is nothing but the difference in density that the outgoing gas and air have, multiplied by the height of the structure. It follows that the diameter of the structure depends on the amount of fuel that can burn out in an hour, i.e. from boiler power.

As a result, the instruction for performing the calculation is as follows:

- If the capacity of the equipment is known, then the volume of gases at the entrance to the system will be as follows: Vg = B * V * (1 + t / 273) / 360, (in m? / S).

- Since the velocity of movement of gases is known, it is possible to calculate the cross-sectional area of the chimney using the formula - (F =? * D? / 4) = S (in m?)

- According to the formula for determining the area of a circle, it is not difficult to find the diameter of the pipe - dт = v4 * B * V * (1 + t / 273) /? *? * 360, in meters.

Consider an example of calculating a chimney for domestic use. For example, on the grate of the combustion chamber for an hour can burn 10 kg of wood with a moisture content of 25 percent. In this case, under normal conditions, the volume of gases will be 10 m? / Kg.

The inlet gas temperature is 150 degrees Celsius.

The calculation of the diameter is as follows:

- At the entrance, the volume of gases is - (10 * 10 * 1.55) / 360 = 0.043 m? / Sec.

- Now, you can find out the cross-sectional area of the pipe, despite the fact that the velocity of the gases is 2 m / s. For this it is necessary to perform such a calculation - (4 * 0.043) / 3.14 * 2 = 0.027 m ?.

- If we substitute all the obtained figures into the formula for finding the area of a circle, we can get the required diameter - v4 * 0.34 * 0.043 * (1 + 150/273) / 3.14 * 10 * 360 = 0.165m.

Now you can calculate the chimney draft:

- Considering that 10 kg of fuel is burned per hour, we calculate the power as follows: Q = 10 * 3300 * 1.16 = 38.28 kW.

- The thermal coefficient for the pipe being calculated is 0.34. From here you can calculate the heat loss per meter - 0.34: 0.196 = 1.73 degrees.

- From 5 meter trunk should be taken away 2 meters of the furnace. As a result, the inlet gas temperature will be - 150- (1.73 * 3) = 144.8 degrees.

- Now you can get the value of thrust. For example, the air temperature is 0 degrees; in this case, the following calculation must be made: -3 * (1.2932-0.8452) = 1.34 mmH2O (natural gas pressure). This value is quite enough for the normal functioning of the gas exhaust system.

This method of calculating a chimney is not as complicated as it may seem at first glance, but, at the same time, it is enough to carry out an effective flue exhaust system for domestic boilers.

Conclusion

Proper calculation is required for the construction of any chimney. Otherwise, the system of removal of combustion products may function inefficiently or significantly pollute the environment, which is unacceptable.

For a household chimney, you can perform such a calculation yourself, but professionals should design the system for industrial equipment. From the video in this article, you can get more information on this topic.