How to calculate the volume of the pipe and its surface

When calculating heating systems, it is often necessary to calculate the volume of coolant and heat exchange surface. How to do this, having only the information that is present on the price tag in the store?

Let's try to figure it out.

Volume

Let's figure out how to determine the volume of the pipe.

Obviously, you need to know two parameters:

- The length of the pipeline.

- Inner section.

The length of the pipeline in an already constructed heating system is easy to measure with the help of a conventional tape measure. The method of calculating the cross section depends primarily on the shape - round, square or rectangular. Let us consider all three cases.

To clarify: the pipelines are practically not used when distributing water or heating. Plumbing or the owner of the cottage calculation of the cubic capacity of the pipework may be needed unless in the case of using the heating register of the exotic form.

Round

The area of a circle, as is known, is calculated as the product of the number pi by the square of the radius. The radius is half the diameter. In theory, everything is simple, but that's bad luck, for water and gas pipes, sellers and manufacturers specify only the remote control (conditional passage) and the type is light, ordinary or reinforced.

How to calculate the volume of the pipe based on this data?

GOST 3262-75, which regulates the production of the corresponding products, will come to the rescue.

| Conditional pass | Outside diameter | Pipe wall thickness | ||

| Lungs | Common | Amplified | ||

| 15 | 21.3 | 2.5 | 2.8 | 3.2 |

| 20 | 26,8 | 2.5 | 2.8 | 3.2 |

| 25 | 33.6 | 2.8 | 3.2 | 4.0 |

| 32 | 42.3 | 2.8 | 3.2 | 4.0 |

| 40 | 48.0 | 3.0 | 3.5 | 4.0 |

| 50 | 60.0 | 3.0 | 3.5 | 4.5 |

| 65 | 75.5 | 3.2 | 4.0 | 4.5 |

| 80 | 88.5 | 3.5 | 4.0 | 4.5 |

| 90 | 101.3 | 3.5 | 4.0 | 4.5 |

| 100 | 114.0 | 4.0 | 4.5 | 5.0 |

| 125 | 140.0 | 4.0 | 4.5 | 5.5 |

| 150 | 165.0 | 4.0 | 4.5 | 5.5 |

The calculation algorithm is as follows:

- We find the desired remote control (conditional passage, or nominal diameter) in the left column of the table.

- Subtract from the corresponding outer diameter twice the wall thickness corresponding to your type of pipe (light, ordinary or reinforced).

- The resulting internal diameter is divided by two and we obtain the radius of the internal section.

- We calculate this section by the formula S = Pi * R ^ 2.

- Multiply the value obtained by the length of the pipeline. The result is his cubic capacity.

Information is better perceived when the instruction is accompanied by an example.

Let's calculate the internal volume of a 40-millimeter filling of 50 meters of heating, made of reinforced pipes.

- Outer diameter in accordance with table - 48.

- Subtract from it the double wall thickness: 48 - (2 x 4) = 40.

Note: the exact match of the remote control with the actual internal diameter is the exception rather than the rule.

- Thus, the radius will be equal to 20 millimeters, or (for convenience of further calculations) 0.02 m.

- The section is 3.14159265 x 0.02: 2 = 0.00126 (with rounding) m2.

- The cubing capacity of the filling is calculated as the product of the section over the length: 0.00126 x 50 = 0.063 m3. To get the result of the calculation in liters, it is enough to multiply it by 1000; In our case, filling a filling will require 63 liters of coolant.

Square

How to calculate the volume of the pipe with its square profile? The area of the square is equal, sorry for the involuntary pun, the square of his side. The side in our case corresponds to the result of subtracting the doubled wall thickness from the size of a square tube.

So, with a size of 100 and a wall thickness of 5 mm, the side of the inner square will be 100 - (5 x 2) = 90 mm.

Recalculate in meters and raise to the second degree:

- 90 mm = 0.09 m.

- 0.09 ^ 2 = 0.081 m2.

- To calculate the required volume with your own hands, it remains only to multiply this result by the length of the pipeline.

Rectangular

This differs from the scenario described above only in that in order to obtain a cross section, the size of the side of the pipe will have to be multiplied not by itself, but by the size of the second side. The formula, therefore, will be S = (A - n) x (B - n), where S = the desired value, A and B are the sides of the pipe, and n is the thickness of its wall.

An example is a product with a size of 150 x 180 and walls of 4 mm thickness. S = (150-4) х (180-4) = 25696 mm2. To convert the result into square meters, it is multiplied by 1,000,000.

Surface

In the case of the manufacture of a heating register, it is important to estimate not only its volume, but also the heat transfer surface area. The cost of miscalculation is low or, conversely, the excess efficiency of the heater.

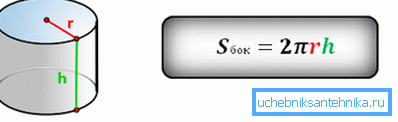

The surface area is calculated as the product of the length of the pipeline on its girth - the circumference of a circle with a circular cross-section and the perimeter with a square or rectangular.

The circumference is, as is well known, the product of its diameter and pi. The perimeter of a square and a rectangle is the sum of their sides.

Let's give some examples.

- The surface area of the round pipeline DN 100 with a length of 10 meters is 3.14 x 0.114 (outer diameter in meters in accordance with the table above) x 10 = 3.5796 m2.

- For a square pipe with a size of 100 mm and a 10-meter length, the result is 0.1 x 4 x 10 = 4 m2.

- For a rectangular section with a size of 80x120 and a 10-meter length, the area is calculated as (0.08 x 2 + 0.12 x 2) x 10 = 4 m2.

Conclusion

We hope that the above calculation methods will be useful to the reader. In essence, the material put at his disposal does not go beyond the framework of the school geometry course (see also the article What is the best pipe for heating: an analysis of the 4 most common options).

As usual, additional thematic information can be found in the video in this article. Successes!