How to determine the size of the pipe in inches: get

The topic of this article is the size of pipes in inches and millimeters. We have to get acquainted with the concept of conditional passage and learn how to correlate its values in different values of measurement among themselves. So let's get started.

Meet: VGP

Products that we have to explore, are used in the installation of water and gas pipelines. Anyone who has ever lived in a Soviet-built house is familiar with them: until very recently, only a steel pipe was used for plumbing.

By the way: according to the current rules, gas within the house and now can only be laid with steel. Despite the decline in popularity of traditional material in the construction of water pipes, he does not give up his positions completely.

Standard

Technical requirements for the production of VGP pipes are contained in GOST numbered 3262-75.

Let's highlight the key points of the document:

- All products manufactured according to this regulatory document are electrowelded, that is, they are obtained by rolling a flat billet in the mill and boiling the longitudinal seam.

- The length of straight segments - from 4 to 12 meters. The length can be unmeasured, dimensional and multiple dimensional; in the latter case, a 5 mm stock is made for each cut.

- Within the framework of the standard, not only black steel products are produced, but also products with a zinc anti-corrosion coating..

An important point: when assembling a plumbing or heating system made of galvanized, only screw connections are used. The instruction is related to the fact that zinc burns on the welds. As a result, when using welding, we, in fact, get a pipeline unprotected against corrosion, the running meter price of which is one and a half times higher than that of black steel.

- The ends are cut at right angles to the longitudinal axis. Burrs should not exceed 0.5 mm.

What are the maximum tolerances?

| Conditional pass | Maximum permissible deviation of the outer diameter | |

| Normal manufacturing accuracy | Increased manufacturing accuracy | |

| 40 or less | +0.4; -0.5 mm | +0.4; -0.4 mm |

| Over 40 | +0.8; -one% | +0.8; -0,8% |

Stop. What is this concept - conditional passage? Obviously, this is not the same as the outer diameter, since the latter has some tolerances for a fixed conditional passage.

Assortment

This simple thought leads us to the search for the definition of a remote control, or conditional passage, and at the same time to a range of products for the installation of water and gas pipelines.

So, the main parameter, which is registered in the table of the assortment - conditional passage, or nominal diameter, traditionally abbreviated as DU. This parameter approximately corresponds to the internal diameter of the pipeline and indicates its compatibility with a certain size of fittings for pipes and valves.

Unclear? Let's use the examples.

| Conditional pass | Outside diameter | Pipe wall thickness | ||

| Lungs | Common | Amplified | ||

| 6 | 10.2 | 1.8 | 2.0 | 2.5 |

| eight | 13.5 | 2.0 | 2.2 | 2.8 |

| ten | 17.0 | 2.0 | 2.2 | 2.8 |

| 15 | 21.3 | 2.5 | 2.8 | 3.2 |

| 20 | 26,8 | 2.5 | 2.8 | 3.2 |

| 25 | 33.6 | 2.8 | 3.2 | 4.0 |

| 32 | 42.3 | 2.8 | 3.2 | 4.0 |

| 40 | 48.0 | 3.0 | 3.5 | 4.0 |

| 50 | 60.0 | 3.0 | 3.5 | 4.5 |

| 65 | 75.5 | 3.2 | 4.0 | 4.5 |

| 80 | 88.5 | 3.5 | 4.0 | 4.5 |

| 90 | 101.3 | 3.5 | 4.0 | 4.5 |

| 100 | 114.0 | 4.0 | 4.5 | 5.0 |

| 125 | 140.0 | 4.0 | 4.5 | 5.5 |

| 150 | 165.0 | 4.0 | 4.5 | 5.5 |

For example, a pipe DN 32 (the conditional passage is indicated without naming quantities, although millimeters are implied when evaluating it) has an outer diameter of 42.3. Depending on the version, the internal diameter can be equal to 42.3-2.8x2 = 36.7; 42.3-3.2x2 = 35.9 and 42.3-4.0x2 = 34.3.

Despite the scatter of the internal sections, all these products are compatible with the DN 32 valve. Each of them can be cut to a pipe thread of an appropriate size that fits perfectly into the internal thread of the valve and, after reeling, will ensure the tightness of the connection.

Pipe threads

The nightmare is not over yet, dear reader.

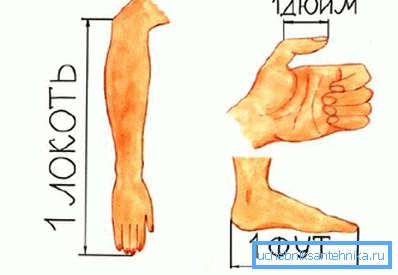

Pipe threads are traditionally measured not in millimeters, but in British inches. The reason is that the relevant standard (NPS, Nominal Pipe Size) is of North American origin.

Reference: the British inch is 2.54 cm. Therefore, in theory the dimensions of pipes in inches and centimeters should be related as 1: 2.54.

Check out our theoretical studies. Fortunately, there is no need to go far: a table of pipe sizes in inches and millimeters is contained in the text of the same NPS. We give the most popular values used in the construction of communications within private and apartment buildings.

| Pipe thread inches | Conditional pass |

| 1/2 | 15 |

| 3/4 | 20 |

| one | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 80 |

| 3 1/2 | 90 |

Now compare the standard size of the pipe in inches and mm.

- The dimensions of the half-inch pipe should be 25.4 / 2 = 12.7 mm. According to the table, it corresponds to DU 15. Next - worse: the actual dimensions of the pipe is 1: 2 inches (outer diameter according to GOST 3262-75) and are altogether 21.3.

- Pipe 1 inch dimensions are not 25.4, but DN 25 (outer diameter 33.6).

- Another size - a pipe 2 inches (2 x 25.4 = 50.8) - corresponds to DN 50 with an outer diameter of 60.

Conclusion

It is quite clear. Pipe sizes in inches and mm are nonlinearly correlated, with no constant proportion. Alas, the table of their relationship can only be remembered. As usual, the video in this article will please the reader with additional thematic information. Successes!