How to increase the heat output of the heating pipe - in

Today the issue of energy saving is very acute. This applies to virtually every user. Therefore, designing heating systems in private construction on their own, zealous owners immediately think about heating systems and their efficiency.

It is more difficult for those who exploit the previously created heating systems, since they are asking themselves to increase the share of heat transfer in ready-made objects.

Ways to increase heat transfer

Let's start the article directly with how to increase the heat output of a pipe in a country house (read also the article Flaring Copper Pipes: consider the available tools and methods).

At the moment there are several ways to increase the heat output from the already created and used, but not meeting your expectations heating system:

- Installation of convectors. This construction of a pipe with metal plates strung on it is made by hand or factory made.

- The color of the main pipeline in black or another dark color. This method, for all its simplicity, is quite effective. In addition, the color scheme can organically fit into the modern interior design, unlike the recent past, when it was considered a necessary measure.

Note! The paint is only an additional method, which is relevant in rare cases, as the efficiency is too low to “admire” the black stripes.

- Installation in the heating system of registers. The register consists of several large-diameter pipes interconnected and with welded ends. These designs include heated towel rails in the form of a coil with several loops.

- Rearrangement of radiators with the addition of sections. This option is the most expensive, but in terms of efficiency it is higher than the others.

Recommended! Do not forget that the installation of additional insulation materials also allows you to increase heat transfer, reducing the loss of heat generated. However, it is possible only when constructing a residential building from the foundation, or when dismantling the facade.

New construction

The design of the heating system of a new building must be carried out with due account for the principles of energy saving. The basis of the project is the calculation of heat transfer, in other words, the amount of heat released from the surface of pipes and other elements of the heating system to the environment.

This calculation is necessary for:

- Determine the optimal parameters of the heating system to create a certain temperature in the premises of your home.

- Decisions on measures of heat insulation taking into account heat losses through the basic structures of the structure.

Previously, the heating trunk pipelines were made mainly of steel products, but today more practical and reliable materials are used. For example, polypropylene products have several significant advantages: low weight and low elasticity, which increases strength.

Calculation of heat transfer

Before you begin construction work, you must make the necessary calculations to maximize the benefits of heating pipes. If you do not know which formulas to use and how to calculate correctly, the following instructions will help you with this.

Independent calculation of the heat transfer surface of the pipe is performed according to the formula Q = K x F x? T, where:

- Q - the required heat transfer, Kcal / h.

- K - heat transfer coefficient of water in the pipe, Kcal / (m2 x h x 0WITH).

- F - heated surface area, m2.

- ?t is the thermal pressure, 0WITH.

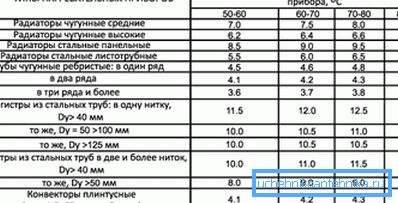

The thermal conductivity coefficient (K), in turn, is calculated using complex formulas, so we use a ready-made value from technical sources - from 8 to 12.5 Kcal / (m2 x h x 0C) for steel pipes.

The surface area of the pipe is calculated from the geometrical formula familiar to everyone from the school curriculum to determine the lateral surface area of the cylinder F = P x d x l, where:

- P = 3.14 is the mathematical constant.

- d - diameter specified in meters.

- l is the length of the pipe, also in counting in m.

To calculate the thermal pressure there is a formula? T = 0.5 x (tP + tabout) - tat, Where:

- tP - inlet coolant temperature.

- tabout - temperature of the heat carrier at the exit.

- tat - room temperature.

The theoretical heat transfer of the steel pipe is calculated taking into account the conventionally set values of the coolant temperature at the inlet-exit and room according to the SNiPs, which are:

Note! For more accurate and easy calculation of the required indicators, special documents are used, such as, for example, a heat transfer table of 1 m steel pipe. Please note that it is only suitable for steel products.

- tP = 80 degrees

- tabout = 70 degrees

- tat = 20 degrees

As a result of simple calculations (0.5x (80 + 70) -20), we obtain the value of thermal pressure? T = 55 degrees.

Calculation example

Perform a theoretical calculation of heat transfer for the most running in the heating system of a steel pipe with a diameter of 25 mm and a length of one meter.

Attention! In order not to get confused in the units of measurement in the course of the calculation we use one indicator - meter.

- First, we calculate the area of our pipe segment F = 3.14 x 0.025 x 1 = 0.0785 m2.

- Next, we look at the table of heat transfer coefficients for steel pipes with a diameter of 25 mm. It is (for pipes with a diameter of up to 40 mm, laid in one line with a theoretical thermal head equal to 55 degrees) K = 11.5.

- We apply the basic formula and obtain the heat transfer value Q = 11.5х0.0785х55 = 49.65 Kcal / h.

At first glance, the calculation is quite simple, but it is in theory.

To create a project of a real heating system, careful calculations are necessary taking into account the parameters of all the elements that make up the system, including:

- Heating appliances.

- Fittings and valves.

- Bypass lines.

- The warmed sections of the highway, etc.

Tip! To design a complex heating system for a large house, it is better to turn to the help of professional heat engineers. The price of their services is much less than the cost of possible losses due to errors in the calculations.

By analogy with the calculation of the parameters of a steel pipe, the heat transfer of a copper pipe or any other is calculated; for this we have placed in this article several useful and informative drawings.

Excellent heat transfer of the metal-plastic pipe and other advantages make it the most preferable option when creating modern heating systems, including alternative ones. Therefore, if you are just starting to build a country house, then you should opt for this modern material.

Conclusion

As you can see, in fact, nothing complicated is in the correct calculation and increase in the efficiency of the system of the negotiated systems. The main thing to remember is that in some cases, high heat output of heating pipes can lead to large annual costs, so you should not get involved in this process either (see also the article Need for an Additional Pipeline: How to Install a Tube).

In the presented video in this article you will find additional information on this topic.