How to make a double bed from a profile pipe

Choosing upholstered furniture for your apartment, cottage or a country house, it is not always possible to find a decent and suitable thing for sale that would fully meet all the requirements. In addition, modern factory furniture, designed for the mass consumer, is made, as a rule, from cheap chipboard and wood-fiber materials, which are not distinguished by their reliability and high durability.

For this reason, many owners for the arrangement of their homes have resorted to the independent manufacture of objects of upholstered and cabinet furniture, as well as all sorts of parts of the home interior.

Homemade double bed

As an illustrative example, this article will discuss the simple technology of self-manufacturing double bed from inexpensive and affordable materials.

In addition, a step-by-step instruction will be presented here, which describes in detail the sequence of all technological operations when performing this simple work.

The advantages of self-made furniture

Despite the wide choice of furniture products, with a small home workshop and a minimum set of joinery and metalworking tools, almost any element of a furniture set can be made by hand at home.

Compared with the purchase of furniture of mass factory production, independent production of a bed has some advantages.

- Individual development and author's design allow you to create a unique and unique thing., which analogues can not exist in principle.

- Performance of work according to own drawings gives the chance to make a bed practically of any form and the sizes, based on the characteristics of the layout of the room, as well as personal preferences or atypical anthropometric indicators of a person.

- The use of high-quality and high-quality materials, as well as a conscientious approach to work significantly increases the reliability and durability of the finished product.

- The final price of making a bed, even with all the costs, will be much cheaper than buying similar piece of furniture in the store.

Selection and preparation of material

The bed, in contrast to other items of furniture, besides static load, in the process of use constantly experiences a dynamic load, therefore for its manufacture it is necessary to use materials possessing high fatigue strength.

At all times, the most suitable material for these purposes was considered to be an array of natural wood, but in modern conditions it is more expedient to use steel tubes.

As a lightweight version, you can make a small children's bed from polypropylene tubes, which have the necessary strength and rigidity.

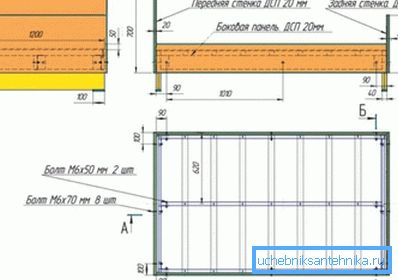

- First of all, you need to develop a detailed drawing of the bed, in which the main view and two main projections should be shown, indicating all the required dimensions.

- For the manufacture of supporting structural elements, it is best to use a St3 60x30x2 mm profile pipe, and for auxiliary elements - a St3 40x20x1.5 mm pipe or a St3 angle 40x40x4 mm.

- From the whole whip of the profile metal with a detachable machine you need to cut the required number of pipes in accordance with the dimensions indicated on the drawing.

- After cutting the material, clean the burrs from the ends with a petal grinding wheel, and wipe the surface of the pipes with a cloth moistened with acetone to remove the preservative grease.

- Using an electric drill or a drilling machine, drill all necessary holes in exact accordance with the dimensions shown on the drawing.

Assembly technology

After preparing all the structural parts of the steel tube, making sure that they are the right size, they must be painted in any suitable color. This can be done manually using alkyd enamel, but it is better to put all the parts in powder painting for steel pipes before assembly.

In order to assemble the finished bed with your own hands from a profile pipe, M6x50 bolts and M6x70 furniture bolts, Li4.2x19 self-tapping screws, 10 mm wrenches, laminated chipboard panels, wooden slats and a finished orthopedic mattress are needed.

- From a 60x30 mm pipe using M6x50 bolts and metal corners, you need to assemble a rectangular support frame with a longitudinal cross member.

- From the inside to the supporting frame to attach the support legs, in the lower part of which you need to install plastic plugs.

- On the inside of the side pipes and on both sides of the longitudinal cross member, attach support guides from the metal angle of 40x40 mm or pipe 40x20 mm with the help of M6x50 bolts along the entire length.

- Fasten wooden lamellas to the support rails using Li4.2x19 self-tapping screws, evenly distributing them along the entire length so that the distance between them is 120-150 mm.

Tip! If there is a welding machine, electric welding can be used instead of bolts to connect the non-separable structural elements of the bed.

Exterior Decorative Trim

After the final assembly and tightening of all bolted joints with wrenches, a rigid stable frame made of pipes with legs is obtained; however, in order to give the bed a finished look, it is necessary to finish the decorative finish.

- Attach long, narrow panels of laminated chipboard with trimmed edges to the lateral longitudinal pipes using furniture bolts M6x70, releasing them a few centimeters above the longitudinal pipe.

- In the same way, attach the front panel of laminated chipboard to the front cross tube so that it does not reach the floor a bit.

- Before installation, it is recommended to stick sheet foam rubber with a thickness of 40-50 mm before installation, and then to wrap it with fabric or artificial leather, and then fix it to the rear cross tube of the bed.

- Insert an orthopedic mattress into the formed box of chipboard panels, placing it under the bottom plane on wooden lamellae.

Tip! In a similar way, a light cot can be made from polypropylene pipes and sanitary fittings, which can be fastened together by means of a bolted or heat-welded joint.

Conclusion

After reading this article, it becomes clear that if you have your own workshop and a minimum set of tools, independent production of upholstered furniture is quite affordable for any home craftsman.

For more information on the subject of interest, you can watch the video in this article or read similar materials on our website.