How to make boxes for pipes of plasterboard heating

To achieve a decorative effect, many individual developers are trying to close the elements of communication systems with finishing materials. This also applies to heating networks, so a box for heating pipes is often arranged. In the course of work, drywall is usually used, which is fastened with screws to the metal frame.

The advantages of this option

Such designs allow you to hide unsightly pipelines, giving the room a representative appearance. In more detail to consider the most important advantages of the method proposed below.

After that, you can decide on the final choice.

- The price of the materials used is low, so it is possible to create low-cost structures capable of closing pipelines located both vertically and horizontally.

- A simple method of the device provides the ability to carry out installation work with their own hands. Due to this, it is quite realistic to save, as hired labor is not required.

- Aesthetic parameters of the structure are at the highest level. Due to the flexibility of drywall sheets, it is possible to create structures not only with straight lines.

- The frame made of metal can achieve sufficient strength to withstand the effects of a mechanical nature.

Addition! Directly into the box, you can embed a decorative grille, so that the air in the room further heats up from the pipelines. Such designs look no less impressive.

Assembly process

Before starting work on the manufacture of this design, it is necessary to prepare the pipelines. It is desirable to additionally protect them from rust with the help of special compounds. All the gaps between the elements and the side surfaces should be sealed with cement-sand mixture.

Basic materials

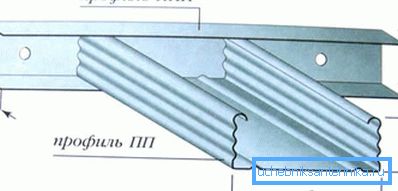

- Ceiling and guide profiles of metal needed for the formation of the frame.

- Sealing tape is required to be inserted between the wall and the supporting structure elements.

- With the help of dowels, metal profiles will be attached directly to the side plane.

- Plasterboard sheets with a thickness of 12.5 mm act as the main material for closing the space inside.

- Reinforcing tape is needed to close the joints between sheets of drywall.

- The surface of the box is treated with a primer to improve the adhesion with the finishing coating.

- Putty is used as a finishing layer, which is applied at the very end.

- Self-tapping screws are necessary for fastening sheets to a metal frame.

Device supporting structure

With the help of metal profiles can create a reliable system for fastening drywall. To serve as long as possible, it is necessary to build it correctly.

The instructions below will help to do this, since all operations are described sequentially.

- At the very first stage, the marking is carried out, that is, the lines are drawn in those places where the profiles will be located. In the course of work, a level must be used so that the stripes do not deviate from the horizontal or vertical.

- A profile is applied to the drawn lines, after which points are marked at which the fastener will be located. Drilling under the dowels is made in these zones. The drill is used as the main tool.

- Next, the fastener is driven directly into the hole, fixing the metal profile to the wall or floor, depending on the location of the pipelines. Under the elements enclosed sealing tape.

- After fixing the elements located on the edges of the planes, you can proceed to the installation of the external profile, which, thanks to the lintels, forms the corner of the drywall construction.

Note! To make the box tough, you must install jumpers at a distance of no more than 30-40 cm from each other. Otherwise there is a risk of damaging the drywall if accidental mechanical action occurs.

Trim and finish

Once the supporting structure of the metal elements is completed, you can begin finishing.

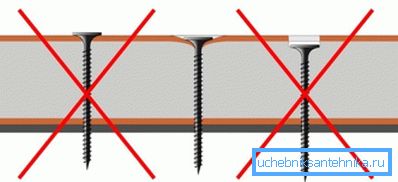

In the process of fixing plasterboard sheets, self-tapping screws for metal of at least 30 mm in length must be used, otherwise the quality of fixation will not be very high.

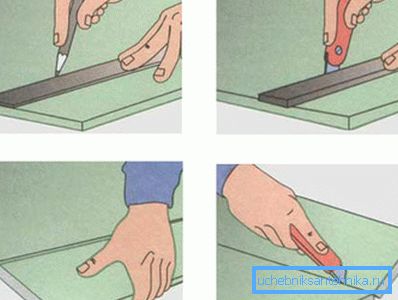

- Ready sheets are taken and cut to the size of the prepared metal frame. Cutting material is a construction knife. The length should be adjusted so that the release of the blade does not exceed the thickness of the sheet.

- Finished canvases are attached to the supporting structure so that the projections do not work out.. Screws are screwed at a distance of 10 mm from the edges. The distance between them should not exceed 35 cm. The optimal depth of entry is 1 mm.

- After fixing the sheets of drywall, the seams are glued with a reinforcing tape, after which the surface is covered with a finishing layer of putty. When drawing the main mix the pallet is used.

Attention! If the box is made in rooms with dry mode, then it is recommended to choose putty on the basis of gypsum. In other cases, it is desirable to purchase cement or polymer products.

As a conclusion

Knowing the basics of assembling a metal frame for heating pipes and the rules for handling plasterboard sheets, you can create an aesthetically attractive box by closing the pipes of the heating system with it. If all work will be carried out to meet all requirements, then such a construction will last a long time without any maintenance. In order to better familiarize yourself with the basics of mastery, it is proposed to further study the information on the video.