Pipe cross-sectional area: calculations and formulas

In the manufacture of pipelines for various purposes, it is very important to choose the right capacity of the structure in accordance with the pressure in the pipeline. However, this parameter very often depends on the diameter of the materials used, but in almost all tables a completely different value is used. That is why the question of how to calculate the cross-sectional area of a pipe is very interesting for modern designers.

Initial data and calculations

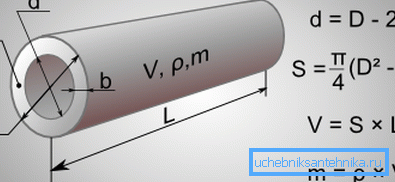

To begin with, it must be said that the design of products of this type is actually a cylinder. Given this, and should select special formulas that are known from the initial course of geometry.

However, it is worth noting that the gauge of round pipes according to GOST is quite diverse and this should be taken into account when working with data.

Formulas

- Usually the area of a circle is found using the formula S =? • R2.

- In this case, the letter R implies the radius of the pipe itself, and the letter? is a constant equal to the number 3.14.

- However, such a formula for the cross-sectional area of a pipe makes it possible to obtain data with regard to the walls themselves, which can only be useful for the breakdown of passage holes. To estimate the throughput we need completely different calculations.

- Taking into account all the features of the materials used, one should obtain the area of the living section of the pipe, where the thickness of the walls is also taken into account. This formula looks like this: S =? • (D / 2-N) 2

- In this situation, the letter D indicates the outer diameter of the product, which is easy to measure with a ruler or looking at the specification. The letter N means the wall thickness of the pipe. This is often determined by the range of steel pipes of circular cross section, and this value can also be obtained from the specification or with a ruler.

Tip! Some designers use numbers to get more accurate data? with a large number of decimal places. However, even for especially critical systems, a value of 3.1415926 is used as it.

Programs

In modern construction, the calculation of the area of a circular pipe is performed using special software. Usually masters use full-fledged calculators, allowing to obtain a variety of data, where the whole system is assigned to pipes. However, there are also programs developed only to obtain this data.

Most of these calculators are designed for use on any platform, so they can even be installed on a mobile phone to get the opportunity to find out the cross section of the pipe for heating directly at the place of work without resorting to self-calculation.

It should be noted that this kind of software can be developed by a variety of companies. Therefore, before you start using it, you should make sure that it uses a metric measurement system. Otherwise, you can get the moment of resistance of the cross section of the pipe or other data in units that will have to be further processed.

Tip! Before using such calculators, it is necessary to make their tests to make sure that the calculations are correct. Some software products of this kind are assembled hastily and do not meet all the necessary requirements.

Field of use

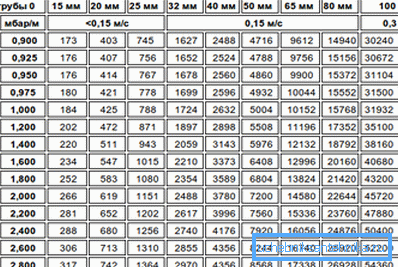

- First of all, the parameters obtained are used to establish the flow of water in a round tube. This is very important when working with expensive liquids or gases, for which the pipeline is going to.

- It is believed that the calculation of the amount of water over the cross section of the pipe is the most accurate and with a known pressure value all the necessary data about the system can be obtained.. It is often used in production and in the creation of cooling systems.

- If the system is created by own hands for domestic purposes, then it is not necessary to know such parameters.. However, with a branched plumbing such calculations can be useful. (See also Pipe Layout: Features.)

- It is worth noting that it is not enough to know all the necessary data, but you also need to be able to apply them.. Therefore, for complex projects it is worth hiring specialists, although their price is sometimes quite high.

- It must be said that in certain cases it is necessary to use materials with a strictly defined cross-sectional area.. This is required by the installation manual, based on the characteristics of the points of consumption or the required final characteristics of the entire system. (See also the article Sewage system: features.)

Tip! Most of the works that involve the use of pipes are based on certain standards and GOST. Therefore, before starting the design, it is necessary to examine in detail all the necessary parameters and select the appropriate equipment.

Conclusion

Having studied in detail the video in this article, you can get more information about this material and the method of determining its dimensions. Also, taking into account the article that is given above, it is worth concluding that it is better to stock up with the appropriate software right away than to make all the calculations yourself.