Profile pipe trusses: efficient systems that require

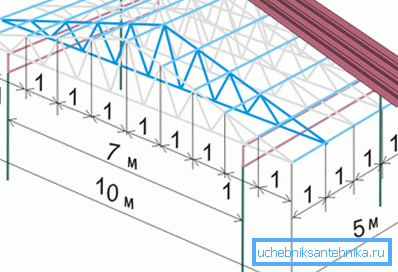

With a large area of construction, premises, facility, the roof should have a very reliable and durable construction. The best option is to use in this case rafters made of pipe metal. They will be a solid, durable, economical design that can span a span of any length. The calculation of the truss from the profile pipe is the most important condition for its proper installation.

Design features

Pipes of this category are produced by rolling, and then processing the metal with the help of special machines.

By type of section, the profile products are divided into:

- oval;

- rectangular;

- square.

Initially, the profile products are round. When it is treated with hot or cold rolled steel, the pipes acquire the necessary shape.

Metal profiled products have different sizes. Their cross-section, minimum, 15? 15 mm, maximum - 45? 5 cm. Wall thickness - 1.12 mm, average length is 6.12 m.

The main elements of the steel truss:

- belts that play the role of the contour;

- racks;

- bracing;

- basic (supporting) brace.

- fasteners: kerchiefs, welding, riveting, bolts, etc.

Types of farms

The instruction reports that trusses assembled from profiled pipes are divided into two types.

- The first of these is systems in which all their parts are connected in the same plane.

- In buildings of the second type, the truss is suspended and includes the lower and upper belts.

The choice of one or another type of truss systems depends on the following:

- loads on the product;

- tilt structures;

- overlap points;

- span length

Tilt angle

Based on the tilt angle, there are the following typical trusses.

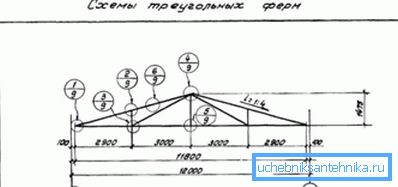

- Construction with a slope angle of 22/30 °. The best option when building a small overlap. In this case, the triangular configuration is best. To determine its height, it is necessary to divide the length of the span by 5. The main advantage of such an analog is a small mass.

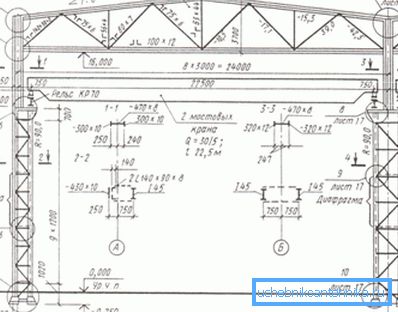

Note! When the length of the span is more than 14 m, it is better to give preference to the truss with braces placed on top / down. A panel, 1.5 / 2.5 m long, is mounted on the top of the structure. A similar truss system contains two belts with an even number of panels.

When the manufacture of trusses from a profile pipe, the length of which exceeds 20 m, is carried out, they are installed using subrafter structures. Bind their supporting columns.

- If the roof has a slope of 15/22 °, the height of the truss is determined by dividing the span length by 7. The length of such systems should not be more than 20 m. If you need to increase the height of the structure, the lower belt is broken.

- When the slope of the roof, less than 15 °, mounted trapezoid product. Its height is determined by dividing the length of the span by the number 7/9. Its exact value depends on the specific value of the slope.

Form of construction

According to the configuration of the truss system of profiled pipes are divided into the following types:

- single slopes, the price of which is the lowest;

- dvukhskatny designs;

- straight farms;

- arched structures.

The outline of the belt

Farms with a parallel belt have such advantages:

- ease of installation, due to the fact that most of the elements are the same;

- the length of the pipe belt and obreshetki the same;

- the number of joints is minimal;

- the design is standard (unified);

- can be used for soft roofing.

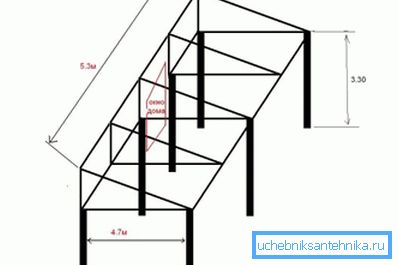

In the manufacture of single-sided truss from pipes with your own hands, you will receive the following benefits:

- hard and durable knots;

- absence of excessively long elements in the center of the structure;

- the cost of construction.

Polygonal structures have their own characteristics:

- they are used for buildings with a large mass;

- during the construction of trusses pipes are used economically;

- the disadvantages of this type of farm - the complexity and complexity of installation.

Triangular structures are easy to install. They are used for roofs with a steep slope. Of the minuses can be noted the complexity of manufacturing support units and high costs of materials.

Crate farms is divided into the following varieties.

- Triangular lattice. It is usually used in structures with parallel sides, less often in analogs of triangular or trapezoidal shape.

- The diagonal type of lathing is laborious and expensive, due to the high cost of materials.

- The lattices of the original forms are equipped, taking into account the features and sizes of the trusses.

Farm calculation

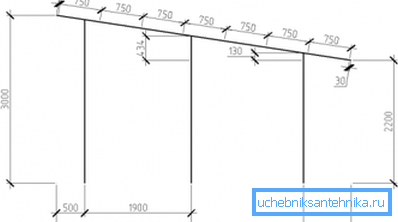

- Before you calculate the farm of the profile pipe, determine its scheme. Specify in it the dependence of the length of the structure on the angle of the slope of the roof.

- Making the scheme, select the contours of the belts. They depend on the purpose of the farm, the type of roofing and the angle of the slope.

- Next, determine the dimensions of the structure. Choosing its length, consider the future angle of the roof. The height depends on the type of floors, the possibility of delivery of the farm and its mass.

- If the length of the structure is more than 36 m, calculate the construction lift.

- Decide on the dimensions of the panels. Do this based on the loads that will affect the product. When designing a truss triangular shape, the angle of inclination should be equal to 45 °.

- The final stage is the determination of the distance between the nodes. Next is a drawing of the structure.

Some tips

The results of the design depend on the slope angle of the roof.

- If it is 6/15 °, a trapezoidal truss should be selected. Its height should be related as 1: 7 or 1: 9 to the span length. If, according to the project, the height of the ceilings (attic, attic) should be greater, polygonal structures are built.

- For single-leaning structures with a slope angle of 6/10 °, it is better to prefer their asymmetric shape.

- When the slope of the roof is 15/22 °, the height at the truss should be related as 1: 7 to the span length. If you need to increase the height of the ceiling, a broken lower belt is mounted.

- If the slope of the roof is 22/30 °, triangular trusses are constructed. Their height must not exceed one fifth of the span length. (See also the article Arbor from a profile pipe: features.)

Note! For the design of the structure and before welding the truss from the profile pipe, read SNiP No. II / 23/81, the code describes the rules concerning metal structures. SNiP No. 2.01.07 / 85 should also be studied, the document covers the topic of loads and impacts.

Manufacturing

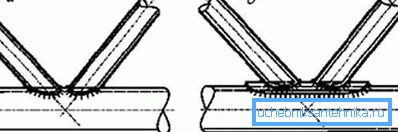

- For assembly or fixation of parts, use paired angles or tacks.

- When mounting the top of the belts, take 2 T-corners having different lengths of sides. Fix them among themselves with smaller slats.

- To connect the lower of the belts, apply angles that have the same side.

- In the production of long and volumetric truss, as fixers, use overhead plates. To distribute the load evenly, use a pair of channel bars.

- Bracing diagonally mounted at an angle of 45 °, racks - at 90 °. To assemble them, use the cross-shaped or T-shaped corners with the same sides. Fix them with plates.

- For the installation of holistic welded trusses are engaged brands.

- To facilitate the construction with a minimized slope, use additional grilles.

- When arranging a long construction, only an even number of panels should be installed.

- The gap between the two farms should not be more than 1.75 m.

- When the assembly of assemblies with the help of tacking ends, the welding of trusses from a shaped pipe begins. You can do it automatically or manually. At the end of welding, all seams are cleaned. (See also the article Butt-Weld Pipe: Features.)

- At the final stage, the product is coated with an anti-corrosion compound, and then with paint.

Conclusion

Systems assembled from profiled pipes are the optimal base for roofing for large and long objects. They are complex and require careful calculations before installation. The video in this article contains additional information on the voiced topic.