Range of profile pipes: we select material in parameters

When designing frame buildings, small-sized architectural forms and other structures, it is very important for the master to thoroughly study the product mix for a profile tube. Fluency in this information allows you to select exactly those elements that in their dimensions will best fit the task.

Below we will tell you what to look for when buying a steel profile, and also give examples of the most commonly used species.

Production technology

Seamless technique

Before studying the profiled tube assortment according to GOST, which is, by and large, a reference document, it is worth analyzing the varieties of this material available on the market. And if you focus on manufacturing technology, then you need to allocate only two classes: seamless and welded tubes.

Products manufactured using seamless technology are distinguished by a monolithic wall structure, which provides the pipe with much greater strength at the same metal thickness. In this case, of course, the price of the material will be slightly higher.

The manufacturing process itself largely determines both the allowable dimensions and operational properties:

- As a blank, square or rectangular steel bars are used. As a rule, high-alloyed and stainless steels are used for the production of profile rolled products.

- The bar is heated in a furnace to a temperature above the level of metal recrystallization, after which an internal hole is made in it. To form this hole, either a piercing machine or a hydraulic press is used.

- Then the thick-walled sleeve enters the rolling mill, where with the help of rollers its walls are thinned and the internal cross section is reduced to the nominal one. During the rolling process, the part may additionally heat up (hot deformation) or cool down gradually (cold deformation).

- Upon completion of the molding, finishing is performed: tempering, quenching, and application of an anti-corrosion coating, etc .. Then the pipes are cut into separate pieces according to the meter.

Quality control is also an obligatory stage: the compliance of the main parameters (cross section, wall thickness, etc.) with the standard values is checked. In this case, the basic range of the profile pipe according to GOST 30245 2003, as well as the approved list of tolerances is used as the basic document.

Welded technique

According to the welded technology, the pipe is made differently:

- Sheet steel is first cut into strips. GOST 30245-2003 recommends the use of general purpose materials, high-alloyed and high-carbon with a thickness corresponding to the design wall thickness.

- Then the strips arrive at the folding section, on which a box of specified sizes is formed from a special device.

- Next, the edges of the box are welded to obtain a closed profile. The weld is subjected to stripping to a protrusion of no more than 0.5 mm.

- All the following stages are carried out in the same way as in the case of the production of a seamless shaped pipe: the products are processed, cut into fragments and undergo quality control.

Note! The above instructions are typical. In some cases, for example, when producing a large-sized profile, or using specific materials, additional operations may be introduced into the process.

Main dimensions

Typical assortment

One of the advantages of the profile pipe, which explains the highest level of its demand as a building material, is a wide range of products. Rather simple production technology allows to obtain parts of the most different sections, which facilitates the selection of elements for structures.

The main parameters are:

- Section or size - the ratio of the length of the sides of the product.

- Wall thickness

- Specific weight - weight of one meter of pipe.

Note! The weight and thickness of the wall are directly proportional: with an equal length of the product and the same cross section, due to this parameter, the mass may differ several times.

As for length, the most common sizes will be 6 and 9.5 m. However, when ordering a large number of products, it is possible to produce blanks to the exact size - so we don’t have to spend time and effort on adjusting the size with our own hands.

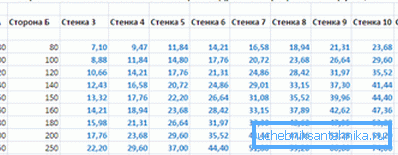

Below is a table of the assortment of shaped pipes of different sections, using the data from which you can not only find the right material, but also approximately calculate the mass of the structure:

| Standard size, mm | Pipe wall, mm | Weight of one running meter, kg |

| Square | ||

| 15x15 | one | 0.48 |

| 15x15 | 1.5 | 0.7 |

| 15x15 | 2 | 0.93 |

| 20x20 | one | 0.6 |

| 20x20 | 1.5 | 0.9 |

| 20x20 | 2 | 1,3 |

| 30x30 | one | 0.9 |

| 30x30 | 1.5 | 1.4 |

| 30x30 | 2.5 | 2.3 |

| 50x50 | 1.5 | 2.3 |

| 50x50 | 2 | 3.1 |

| 50x50 | 2.5 | 3.9 |

| 60x60 | 2 | 3.7 |

| 80x80 | 3 | 7.1 |

| 100x100 | four | 12.05 |

| Rectangular | ||

| 20x15 | 1.5 | 0.8 |

| 20x15 | 2 | 1.1 |

| 20x30 | 1.5 | 1.2 |

| 20x30 | 2 | 1.6 |

| 30x50 | 1.5 | 1.8 |

| 30x50 | 2 | 2.5 |

| 30x60 | 1.5 | 2.1 |

| 30x60 | 2 | 2.8 |

| 40x70 | 2.5 | 4.2 |

| 30x80 | 2.5 | 4.2 |

| 40x80 | four | 4.9 |

| 50x100 | four | 8.7 |

| 60x120 | four | 10.6 |

Note! The table shows the characteristics of only those products that are used most often. When using other standard sizes it is necessary to be guided by the figures specified in GOST.

The use of pipes of different dimensions

If we talk about the use of profile pipes in the construction and manufacture of frame structures on a metal base, then it should be noted that the range of tasks is very wide.

- Products of small section, such as pipes 15x15, 20x15 or 20x20 mm, are most often used either for making furniture (do we all remember school chairs?) Or for mounting fences. The relatively small size of the parts, combined with a sufficiently high strength, makes it possible to create structures that are light enough and resistant to loads.

Note! Another advantage is the small width of the profile: the use of such elements in assembling the filling of hedges, railings and other similar structures allows minimizing the loss of luminous flux.

- The most common pipes are of medium section: square 30x30, 40x40 and 60x60 mm, and also rectangular - 20x30, 20x40 mm, etc.. They are purchased for the construction of light frame structures (greenhouses, awnings, gazebos), for the construction of lightly loaded bearing elements (fence posts, supports, light columns). Also often similar parts are used as an internal basis for brick pillars.

- “Flat” varieties (from 20x40 to 30x80 mm) are often used in mechanical engineering. Such pipes are characterized by an optimal ratio of mass and mechanical strength.

- In the construction of capital buildings, there are increased requirements for the operational parameters of all parts, because for supporting structures elements from 60x60 mm and larger are taken. Of course, they are characterized by a fairly large mass, and they cost a lot, but in any case, the gain in strength makes such investments fully justified.

As you can see, a wide range of rolled products makes it very versatile - it is difficult to find a construction task, for a solution that could not be used such products.

Conclusion

After examining all available sizes and knowing the weight of 1m of the profile pipe gamut, we will get exactly the information that we need at the design stage of the construction to be constructed (also read the article Stainless steel pipes - harmony of strength and beauty).

That's why you should read GOST before starting work, and for more information, view the video in this article.