Sewer pipe spout - connection features

Pipe connection is the most common method of joining sewer pipes. It provides a fairly simple installation of the pipeline and the tightness of the joints. Next, we take a closer look at the features and types of socketing.

General information

The quality of the joints of all elements of the pipeline plays an important role in the reliability of the sewer system. The ability to break through the system depends on how firmly they are connected. The marriage of the connection, even in the form of the most insignificant burr, will lead to the appearance of a raid in this place and a gradual decrease in the capacity of the pipeline, up to complete blockage.

In this regard, the socket connection has proven itself well, therefore it has been used for many years. Its principle is based on the fact that the bell-shaped sewer pipe, on the one hand, has an extension, which is a seat for another one of the same diameter in the pipe.

To ensure the tightness of the joints they are compacted. Depending on the type of material from which the pipes are made, the method of sealing may be different. Therefore, in the following we will take a closer look at the technologies of bell-fitting of different types of pipes

PVC pipes

Polyvinyl chloride and other plastic pipes can dock in two ways:

| With rubber o-ring | This method of installation is detachable, as if necessary, you can disassemble the pipeline, for example, to replace the damaged part. |

| Adhesive | It is an integral method of installation, as the pipes are glued together. |

Now let's take a closer look at the features of each type of installation.

Rubber ring coupling

This method of installation is the most common for plastic sewer systems. Its meaning lies in the fact that the rubber ring is located in a specially made inner groove.

The ring performs several functions at once:

- Compaction seal;

- The function of the lock ring;

- Partially compensates for the mismatch of the axes of the connected elements.

Instructions for connecting pipes and fittings in this way are as follows:

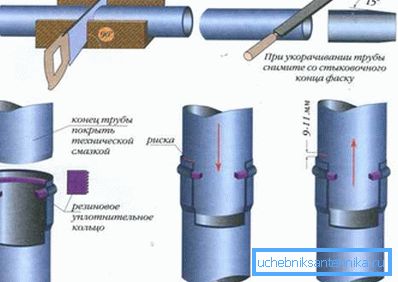

- First of all, it is necessary to clean the sealing ring of the debris and sand, the walls of the socket and the end of the pipe with a chamfered face.. If the chamfer is missing, it must be done with a mounting knife or file, as shown in the diagram.

- Further, in order not to damage the sealing ring during installation, the joint area should be lubricated with glycerin, silicone grease or soap, but not oils.

- Then, connecting the elements, you should make a mark with a pencil extreme position.

- Next, focusing on the mark, you need to pull the pipe back to 9-11 mm. This gap is designed to compensate for the thermal expansion of system components and to prevent internal stresses. For example, polypropylene pipe can be extended up to 5 mm per meter.

Since the fittings are short, when installing them, the gaps can be omitted.

- At the end of the work, the joints must be lubricated with sealant.

Note! Uneven deformation of the sealing ring will lead to depressurization of the connection and, consequently, to leakage. Therefore, it is necessary to ensure that in the composite sections the curvature of the axis does not exceed the wall thickness per meter of the pipeline.

In some cases, there is a need to connect a plastic pipe with a cast iron. In this situation, use a special adapter, which has a double rubber gasket.

Adhesive bonding

Do-it-yourself glue mounting is pretty easy.

The order of action is as follows:

- A special adhesive composition is applied to the flat part of the pipe.

- Then the glue is processed socket.

- Further, the elements are joined and strongly compressed.

- After some time, the glue hardens and the joint becomes airtight.

This method of articulation of the pipeline is used less frequently. It should be noted that the glue joints do not withstand lateral loads.

Cast iron pipes

Cast-iron sewers have recently been used very rarely, since the price of the material is quite high. In addition, they have a lot of weight, resulting in their disassembly and assembly is a rather difficult job.

However, if, for example, cast-iron sewage in an apartment as a whole is in good condition, with the exception of any one element, it makes sense to simply replace it with a new part. In this case, to ensure the tightness of the joints, a staking of the sockets of sewer pipes is performed.

This operation is performed as follows:

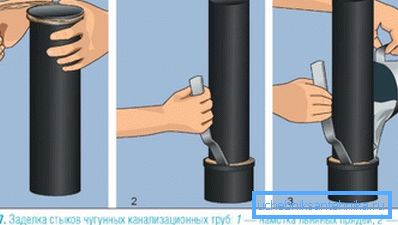

- First of all, the elements of the pipeline are connected.

- In the gap that appears between the socket and the walls of the pipe, the cord is hammered, treated with special waterproof impregnations. This operation is performed with a wooden spatula and a hammer. In this way, 2/3 of the joint space is filled.

- Further, the usual tow, not treated with any impregnations, is also clogged. Its use is necessary in order to ensure good adhesion with cement.

- After that, cement grade M300 is diluted with water in a ratio of 1: 9 and applied over the tow. At the same time it is necessary to tamp the solution well.

- At the end of the work, the joint should be wrapped with a wet rag to prevent cracking of the cement during solidification.

Tip! Despite the fact that such an installation is considered to be detachable, dismantling without damaging the pipeline is often very difficult. Scraping is done with a screwdriver or chisel. In addition, to disconnect the pipes, the junction is heated by a blowtorch.

Here, perhaps, and all the main features of socket mounting pipe.

Conclusion

We have considered the main options for high-quality socket mounting pipe and their features. If not to break these technologies, connections will turn out reliable and durable. Moreover, it’s not difficult at all to do it yourself.

From the video in this article, you can get more information on this topic.