Tank on the pipe - the solution of the issue with hot water

Bath is part of the culture of our people, and every good owner in the construction thinks about the issue of providing hot water. Of course, there are modern systems of heating and automatic supply of hot water, but they are expensive and sometimes such time-tested options as a tank to the pipe for a bath turn out to be more affordable and most importantly economical.

Traditional heating systems

In search of a universal solution, craftsmen have tried many options and each of them is good in its own way.

It is impossible to clearly say that there is a universal option, so you should choose depending on the conditions existing on a specific object.

- In the process of building a bath, many modern owners prefer to go the easiest way and purchase an electric boiler. The option is undoubtedly worthy, but it requires a constant supply of water, plus for large capacity, the cost of electricity will be sensitive.

- Classic is considered to be built in the furnace water tank. Such containers heat up quickly, the installation instructions for such heaters are the simplest, in the most affordable version it is enough to put the tank on the stove. But it will be low and, being in the steam room, will become a source of wet steam, which is not always good.

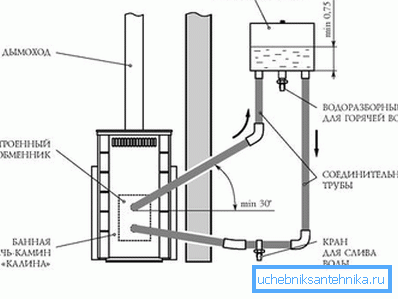

- Well-proven outboard tanks, when the main tank is mounted at a comfortable height in the dressing room or shower, and heating is carried out through a heat exchanger installed in the furnace. They work thanks to the elementary laws of physics, cold water through the bottom pipe enters the heat exchanger and, heating up, returns back through the upper conduit.

- But the most profitable and convenient in operation are the tanks mounted directly on the chimney., about them we will talk further.

Chimney heating tanks

A tank for heating water for a tube is established for a long time; it suffices to recall the legendary Russian samovar, a kind of symbol of our people. This principle was first used in it, for this reason such systems are also called samovar ones.

Advantages of samovar structures

- When the stove is heated in a bath, the pipe in it will heat up anyway, it is silly not to use this energy and it can be safely considered completely free.

- Depending on the type of fuel, the temperature of this part of the design ranges from 300 to 700? C. Moreover, a significant advantage is that the pipe is heated evenly over the entire area of contact.

- The volume of such a tank can be quite large, because the distance from the furnace to the floor will be at least one and a half meters, and such a heater can be equipped along the entire length of the pipe.

- Such a heater, in most cases, does not need an additional pump, heat exchanger or electric heating element.

- A normal oven for a small steam room has an average pipe cross section of about 115 mm. Taking into account the thickness of the tank, the lateral dimensions of the whole structure will be within half a meter. That allows you to place it in any, even a small steam room.

- For installation does not require fundamental knowledge of heat engineering or to be a super-mechanic. Almost any owner will be able to install such a container on the pipe with his own hands.

- And finally, when compared with a boiler, the price of such a miracle will be quite affordable, and the investment will be one-time.

The disadvantages of this type of heaters

- The most significant disadvantage is that the tank for heating water on the pipe can be installed exclusively on metal structures. Ceramics or brick for pipes do not have this level of heat transfer.

- Constructions in which water is poured through the top, directly in the steam room, will increase the level of humidity in the room.

- Hot metal walls of the tank are a source of danger, careless touching can cause injury.

Select the desired capacity

Traditionally it is assumed that one person needs at least 10 liters of water for bath procedures. To this should be added another 10 - 20l for steaming brooms and related procedures. Hence, the minimum capacity of the tank for the rest together should be in the region of 50l, and such a tank can easily fit on a small stove.

But if you expect to bathe a larger company, then it makes sense to mount a large capacity, until the very overlap. But this option has a significant disadvantage, such a construction, in a filled state, will be quite heavy and a reinforced foundation will be required for such a furnace.

The most acceptable is the variant in which the tank for heating water to the pipe works exclusively as a heat exchanger. Here you do not need a large and heavy capacity, 20 to 30 liters is enough. Such a weight can withstand any stove, plus structures of this type are made airtight. Of them are mounted 2 output leading to the remote tank, which can be arbitrarily large.

Important: connecting pipelines between the heat exchanger and the working capacity should not be more than 3 m. For more distant lines, it is necessary to install a forced water injection system, simply speaking a pump.

There is an option to use the inner surface of the tank directly as a pipe, the heating rate in this case increases significantly. But experts advise to pick up the tank so that the tank is tightly worn on the pipe. This option is beneficial in that it does not require a large wall thickness and in the case of a chimney burnout, it will be easier to replace it.

Material for capacity

In the old days, the most popular material was cast iron. Of course, it will heat up a little longer, but then the temperature will keep better. An important factor is the corrosion resistance of cast iron and long service life. But cast iron material is heavy and a strong support is needed for such a capacity.

Ferrous metal for these purposes is now practically not used because of the tendency to corrosion and the high probability of deformation during sudden temperature changes.

Stainless steel is deservedly considered a universal material. This metal is not afraid of corrosion and has a relatively low weight. In order to weld a large-capacity tank, a sheet 1.5 to 2 mm thick is sufficient. During temperature fluctuations such containers are not deformed.

Important: during operation, any heating system for the bath to avoid overheating should be constantly filled. In winter, the water drains, so that the frost does not break the pipe.

The video in this article shows the opinion of a specialist.

Conclusion

Our country is rich in craftsmen, but the bath is considered an object with a high degree of danger. Based on this, we do not recommend installing handicraft tanks. Now there are enough certified products on the market, the price of which is quite affordable.