The range of square pipes: what indicators are most

Square tubes have become widely used relatively recently, but nowadays it is difficult to imagine construction without the use of such elements. Unlike products with a round section, square and rectangular pipes are used not for laying different liquid supply systems, but for erecting structures and other construction works, which we will consider below.

Main areas of use

If you do construction work with your own hands, then square-shaped elements will come in handy in the following cases:

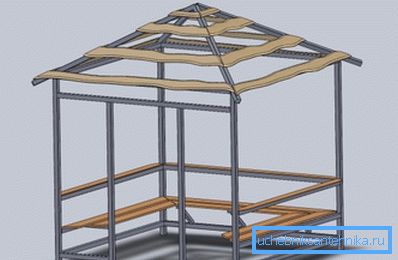

- When building frames of various designs, it is important to choose the optimal size and wall thickness to ensure maximum reliability.. It is very very simple to make a frame from a tinder for a gazebo, a canopy or a visor, because, unlike round pipes, there are even sides here that are very convenient to combine and fasten to each other.

- If you need to firmly strengthen the formwork or add light and durable elements to the foundation, this option will also be an excellent solution..

- Also products of large sizes can be used as posts when installing gates, wickets and fences.. A small pipe can be used for the fence itself, it will turn out very strong and durable.

- Very often such pipes are used in industrial production when creating strong frames., frames and other similar structures.

- In the automotive field, square elements can be used for frames on trucks and to reinforce certain elements of the body with increased loads.

- Another big area is furniture production., Here, products with a decorative coating are most often used: chrome plating, galvanizing or with a colored polymer layer.

The list of indicators affecting the characteristics of the products of this group

The range is a range of products of a particular type, which varies in size, materials used, processing methods and other indicators depending on the type of products. It should be understood that the weight and the gauge of a square pipe are different indicators, with the same weight, products can have completely different characteristics. The main factors affecting the range, are the following indicators:

| Wall thickness | From this characteristic directly depends on the weight of the finished products, as well as their strength. The thicker the walls, the more reliable the resulting structure and the greater its resistance to deformation and other adverse effects. But the price also varies in a fairly significant range, so it is advisable to calculate the optimum thickness even before the purchase of pipes. |

| steel grade | It is a very important indicator, since even thick walls will not give a guarantee of reliability if low-quality material is used in production. GOST for square pipes prescribes the use of certain steel grades, therefore compliance of products with regulatory requirements ensures the reliability of finished structures. |

| Production technology | There are several options for the manufacture of products of this group. At the same time, reliability indicators largely depend on the method used to manufacture products. As a rule, seamless options are most appreciated as the most reliable and durable. |

| Additional processing | Sometimes to increase the resistance of a metal to corrosion and other adverse effects, the surface is treated in various ways. This allows not only to protect the surface, but also significantly improve the appearance of products. |

How do factors affect a product mix?

Note! A wide assortment is an indicator of a high-class manufacturer and the availability of sufficient production capacity to produce a wide range of products. It is impossible to produce a large list of products without appropriate technological equipment.

Regarding square tubes, there are several factors that affect the gauge. All of them are described above, we consider them in more detail.

Manufacturing material

By production metal of the most various brands can be used, but the following options are most often applied:

- Steel 4 (PS, SP or KP).

- Steel 2 (SP or PS).

- Steel 10 or 10 PS.

Most often, the products are manufactured according to GOST 8639-82, which regulates the features of the production of products with a wall size from 1 to 10 centimeters. According to GOST 30245-2003, welded pipes with sizes up to 18 centimeters are most often produced, while the use of material not specified in these documents automatically means that the product will not meet the standards of GOST.

Features of the production process

There are several main options:

- Electrowelded tubular elements made of a curved sheet of a certain thickness. This option differs in small weight, but any construction instruction will not allow its use in the designs which are exposed to high loadings.

- Cold-deformed welded pipes are made from blanks of a certain shape, this option is more reliable due to the peculiarities of production.

- Hot-rolled seamless pipes are among the most popular, as they are very reliable, and at the same time their cost is quite reasonable and acceptable for most developers.

- Cold-deformed elements are the most durable and reliable, this is due to the peculiarities of the production process, the absence of heating allows us to achieve excellent reliability and durability. In addition, such pipes are much less susceptible to corrosion.

Note! Always ask the seller the presence of documents certifying the quality of products.

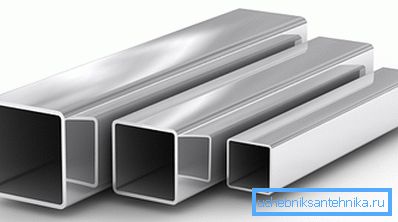

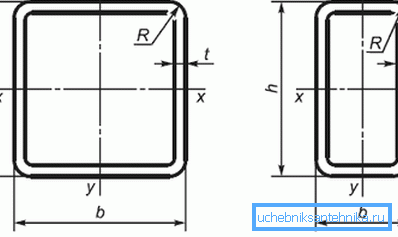

Size range and wall thickness

There are several important requirements in the GOST standards:

- The shape and geometrical dimensions must meet a variety of requirements. The size can vary from 10 to 180 mm.

- The wall thickness can also vary over a fairly wide range - from 1 to 8 mm.

- The magnitude of the errors in the measurement of geometric parameters is very small and varies from 0.8 to 1.3% depending on the size of the product.

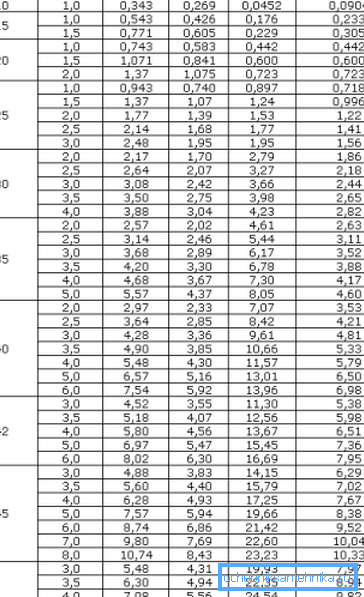

- Pipes of small diameter may have the parameters shown below:

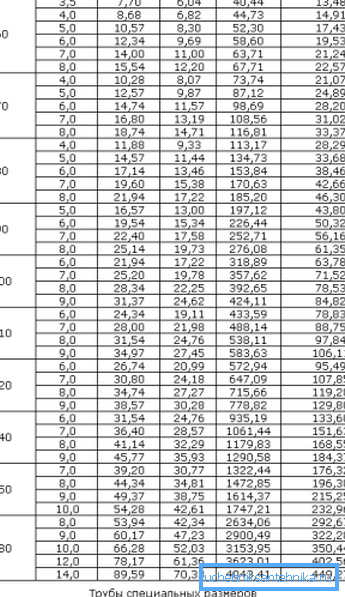

- Larger pipes appeared quite recently, which is why a new GOST was introduced, since the old one regulated the size range to only 100 mm. In addition, products of non-standard sizes are also provided. Basic information on large products and options with special parameters is shown in the table below:

- The length is also regulated, the elements can be both dimensional and non-dimensional, and the indicators vary in a wide range: from 4 to 12.5 for seamless and from 4 to 9 for electric-welded versions.

Conclusion

The use of square pipes greatly simplifies the workflow and allows achieving high reliability of the structures. The video in this article will tell you some important nuances regarding the topic under consideration and will make it possible to sort out some issues even better.