We make the frame of the greenhouse from the profile pipe

Greenhouses, in contrast to mobile greenhouses, are a solid structure, so the frame of the greenhouse from the profile pipe is suitable here, as well as possible. It can be sheathed with the same polycarbonate, which will make it possible to heat the plants not only with heaters, but also with solar energy.

But for the foundation, you can also use pipes made of polypropylene (PP) or polyvinyl chloride (PVC), but this design is more suitable for film coating. Below we will consider different options, and also show you the thematic video in this article.

Different frames

Materials

- In accordance with the requirements of GOST 13663-86, metal pipe profiles can be oval, square and rectangular, and their manufacturing technology can be a) seamless cold-forming; b) seamless hot-rolled; c) electric; c) electric cold-deformed.

- In addition, the instruction on state standards regulates their range, for example, for an oval it is GOST 8642-68, for a square it is GOST 8639-82 and for a rectangle it is GOST 8645-68.

- It will not be entirely correct to assemble the greenhouse frame from PVC pipes, since rigid PVC is more suitable for water pipes, sewage systems and cable channels when installing electrical equipment and communications (telephone, Internet). If you look at PVC from a purely construction point of view, it can be used as a casing for a pile-driven bored foundation, and this is hardly needed for a greenhouse or greenhouse.

- It is quite possible to treat polypropylene in a different way, which is also called ecoplast - the walls of the pipe are quite rigid here, but at the same time they have flexibility and elasticity, which allows you to mount a spherical frame. Of course, the structure of the industrial level of such material can not be erected, but the greenhouse for a country site can be made of them, even conveniently, thanks to the above qualities. Such a structure will have a small weight (PP is very light), and its price is much less than the metal profile. (See also the article Arbor from a profile pipe: features.)

Note. There are hot and cold polypropylene pipes. The difference lies in the fact that the first version is made with an additional reinforcing shell of fiberglass or aluminum foil. But such a gain is important for the temperature difference, so that the PP does not float - in our situation it does not matter.

Frame Forms

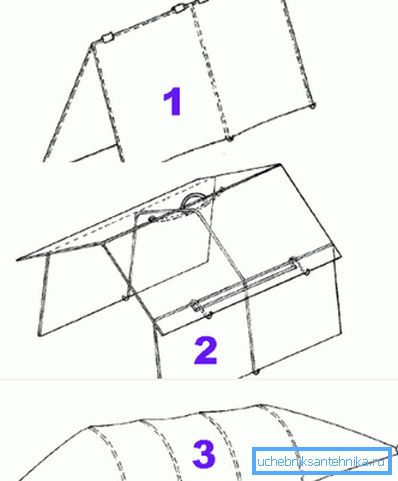

- The first type of frame, which you see in the upper figure, is very similar to a double-slope roof with a steep slope, and can be made of metal or propylene profile, as well as wooden slats and / or timber. As a rule, in such constructions the entrance door is not provided and their covering is a transparent dense cellophane film. If you need to get inside the film simply remove or lift one of its edges.

- The second type, more reminiscent of the shape of the attic, is most often used for stationary greenhouses, where the frame is made of a metal profile (the cross section configuration does not matter) and is covered with polycarbonate. Naturally, in such structures provides the front door and even windows (vents) for ventilation. Assembling the skeleton is most often carried out at the expense of bolted connections, but in some cases this is done by gas or electric welding.

- But the most capacious one can be called a tunnel-type greenhouse, where a spherical roof allows to use free space with maximum efficiency when caring for plants. But such constructions are also made of small sizes from polypropylene pipes, where dense transparent cellophane is used as a coating. For large stationary structures, a metal profile with a different cross section configuration is used, giving it shape with a pipe bender.

Small frame greenhouse for the garden plot

Now we will find out how at home you can make a greenhouse frame from polypropylene pipes with a perimeter size of 30001500 mm, although here, in addition to PP, you can also use a metal rod or fiberglass reinforcement, which is about the same price.

As the basis of the skeleton, you can use a regular wooden rail with a section of 5050 mm, which is very easy to fasten with screws. To do this, you will need two 3000 mm rails and two - 1400 mm each - you will fasten long pieces to the short end, and fasten kerchiefs at the corners to give the rectangle rigidity.

Bolts can also be used to connect the base of 3X1,5m, but this will complicate the design, especially since kerchiefs are still needed for rigidity, because the rectangle can easily turn into a parallelogram. To fix the shape, use two trimming, screwing them diagonally in opposite corners - these small triangles will ensure the figure is still.

If you suddenly need to disassemble the storage base for the winter, you can easily unscrew the screws with the help of a screwdriver so that at any time you can rebuild the structure.

If you use a polypropylene tube for the ribs, then for such a construction you will most conveniently use a cross section of 20 mm. For the installation of the ribs, you will need to drill 7 holes with the same diameter - 20 mm (50 cm apart) in each longitudinal support of the base, but you should make the outer holes no closer than 2 cm from the end so that the wood does not crack.

The depth of each landing nest should not exceed 25 mm - it should not be drilled through, as the skeleton will simply fall through.

Recommendation. When assembling a lightweight frame made of polypropylene pipes (metal or fiberglass reinforcement), do not use any adhesive or sealant. Firstly, the installation of the profile in the hole of unambiguous diameter will be quite dense, and, secondly, we still make a collapsible design.

The length of the polypropylene pipe in the store is 4 m, but if you find such an arc too high, you can shorten it by a meter. But also here it will be possible to go in another way - to increase the transverse base rail by 50 cm, that is, the width of your greenhouse instead of one and a half will reach two meters.

Considering the fact that you will do all the work with your own hands, you can always change dimensions arbitrarily, adjusting to the geometrical parameters of the material you have and the availability of free space in your area.

When the frame is ready, you can proceed to the installation of cellophane film and it will be much better if you use one whole piece - less worries, both at the stretch and during the operation of the greenhouse.

Cellophane can be fixed to a wooden base with a stapler, but you can simply press the edges with a rail or bead, as shown in the top photo, especially since you have to fix one of the ends to be able to access the inside of the greenhouse.

But you can also fix all edges tightly - ventilation and access inside can be provided here simply by lifting one side and substituting any objects under the base. In addition, given the small weight of the structure, it can generally be removed in warm weather.

Conclusion

If you want to make a frame for a greenhouse from a profile pipe for professional growing of plants, then you certainly should stop on metal by covering it with plexiglass or polycarbonate. But in such cases, the base is often poured into a foundation with a low depth of foundation.