What can be done from the profile pipe: application

For the installation of supporting frame structures, for decorative grilles and fences, and even for the transport of liquids and gases, a pipe profile of different sections can be used. And it is very easy to process it with your own hands at home.

The configuration of the cross section of the hollow profile can be of a different geometric shape - it is a circle, oval, square, rectangle and parallelogram. And its production can be either electrowelded or seamless, and its mechanical qualities mainly depend on it.

Now we will talk in more detail about the materials themselves, what can be made of them, and also show you the video in this article.

Pipe profile

Production

Note. Pipe profile is made of low-alloyed and carbon steel sheet, which for this comes in rolls (such blanks are called strips) according to GOST 8645-68 (changes and additions - 01.07.2010).

- As already noted, products can be made from strips on a bending machine, where the sheet is given the desired shape, for example, a rectangle or a square.. Then the edges are compressed using rollers, and the seam is boiled either in protective gas or induction welding (depending on the purpose). This option does not have great mechanical strength, but the frame of the door of this type of shaped pipe will be excellent. Also such products are good for fencing.

- In addition, a ready-made round tube can be fed to the rolling mill, which is rolled out by rolls of the desired shape and size during the rolling process.. As a result, the cross section (rectangle, square, parallelogram) required for this product is obtained. This type of treatment involves two methods - cold or hot deformation. Of course, the second method is more qualitative, since after heating the metal is released (gradual cooling by emulsion), which relieves internal stress, and the profile is not deformed during transportation, storage and processing.

- As you understand, the price and quality of products depends on the production method, and these parameters already directly influence what can be done from it - whether it will be fences from a profile pipe or it can be used to transport heat carriers, for example, for heating registers.

Application area

Despite the fact that the profile can have any shape, for some reason it is customary to call this word only an oval and quadrangular section, although this is also a circle, but it is simply called a pipe. But it's not the name, but the expediency of use.

Such a structural material has a rather small weight, but due to its configuration it has a high bending strength. For example, a chair from a profile pipe will be much lighter than from a reinforcement, but the strength of its frame will exceed that of a similar reinforcement.

Any design requires a certain layout and it does not have to be the work of design designers - a canopy drawing of a profile pipe (or other structure) may in fact prove to be the most common draft on a piece of paper.

So, if you make a sketch of the same shed, then you can correctly calculate the distance between the profiles, thereby determining their number. In addition, you will have the opportunity to estimate where you would like to weld elements of artistic forging, if you want to diversify the design of the structure.

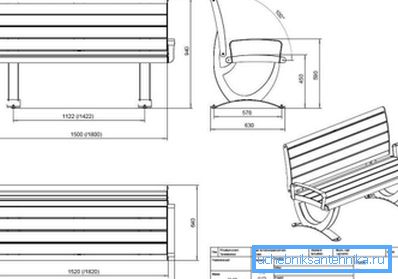

It should be noted that the drawings of the benches of the shaped tube can be very different from each other, since these designs have different purposes (place of operation), different sizes and different shapes.

In the upper photo, a drawing of a garden bench with a back is offered to your attention, which can be used not only in the suburban area, but also in the city park. This design is very convenient for recreation - the back is folded at an angle of 100? - it gives the opportunity to relax the body for rest.

And in this photo you see another similar version of the garden bench, but here the construction becomes somewhat more complicated - the lower part of the frame of the profile tubes is made of a figuratively curved profile, although the overall dimensions are about the same.

The decoration of the legs can be changed to infinity, but the spiral is a very convenient option for mounting - it is easiest to do if you heat the profile in the forge, twist a certain number of turns, and then release it by random cooling to relieve internal stress on the pipe. As you can see, the design is very beautiful and at the same time reliable enough - resistant to mechanical loads.

Metal profile rafters can be used for production shops, hypermarkets, gyms or swimming pools, in short, where you need to cover a large area. To do this, as a rule, apply a profile of rectangular cross-section.

At home, such overlappings are not used - the rafter legs from such a material will be too expensive, and there is no need for such a safety factor either. But for a suburban site you can make a single-barred canopy of a shaped pipe, which will serve as protection from rain and sun for the same firewood, or it can be used as a resting place if you put a bench there.

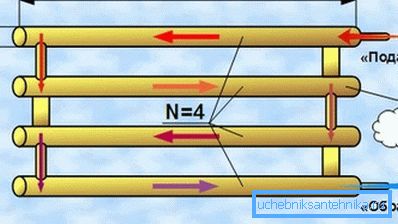

Very often in utility rooms, baths, gyms and production shops you can find homemade registers from a profile pipe, which are much cheaper than radiators and operate on the principle of a coil. For the assembly of such a structure, any section — a circle, an oval, a square or a rectangle — is most important; it is mechanical strength and high-quality welding seam at the joint of the elements.

Note. Please note that for heating registers made of shaped pipes, not the last role is played by the cross-sectional area and the larger it is, the more water will have to be heated, therefore, energy costs will increase. The most suitable section option for the registers is a rectangle 20X40 mm or 4060 mm, and also a circle with a diameter of 40-60 mm. To increase the power of the register, it is better to increase the number of pipes or their length in one design, rather than choosing them with a larger diameter.

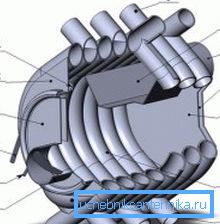

To date, the two-chamber furnace Buleryan or Brenneran has become very popular, as it can still be called. This is a gas generator device with a fuel burn-out chamber - the smoke from the burned firewood does not enter the chimney, but into the second chamber, where all the small particles of the remaining fuel burn out.

Therefore, homemade buleryan from a profile pipe is quite relevant now, but when assembling it, the instruction requires that these same heat exchange pipes be at least 1/3 in the fuel chamber.

Conclusion

The scope of application of such structural material is quite extensive, for example, it can be homemade scaffolding from a profile pipe, which you can successfully use in construction and repair works. Or you can make a bench, stool or chair out of a shaped tube, which will be very useful for a gazebo or even for outdoor use ... Good luck!