What is pipe inch and inch thread

In the designation of pipe diameters using inches, moreover, the size of the pipe inches differs from the conventional one. Often this is confusing for beginners. Next, we consider what constitutes this system of calculus, how it translates into millimeters, and what inch pitch is.

General information

Inch is a unit of measurement that has existed for hundreds of years. Moreover, during this time she changed more than once.

As an example, the following types of this unit of measurement:

- Vienna - 26.3 mm;

- Spanish (pulgada) - 23.2 mm;

- Mexican - 23.3 mm.

I must say that this list can be continued ad infinitum, for example, in each of the Germanic lands there existed its own unit of measure:

- Bavarian;

- Saxon;

- Prussian;

- Badenskaya, etc.

There were similar measures even in China and Japan. For example, the Chinese equivalent was 33.3 mm. However, on May 20, 1875, the International Metric Convention was signed in France. The objective of this treaty was to ensure the uniformity of international metrological standards.

An important note of this contract was the recognition of an inadequate unit that has nothing to do with the existing metric system. Moreover, the OIML recommended removing this calculation from circulation as soon as possible where it was still used.

This recommendation was complied with by all countries with the exception of the United States, where this unit remained the local unit of measurement. This made it difficult to follow the requirements of the OIML in the rest of the world.

So what is this unit of measurement, and how to express it in our usual units of measurement? Nowadays, when referring to this term, the English measure of length is implied. It should be noted that it also changed several times, however, since the 58th year of the last century it is 25.4 mm.

It is called “inch”, and its common sign is quotation marks. For example, 15 means 15 inches, i.e. 38.1 cm

Features tube inch calculus

Conversion to metric measurement system

If the manufacturer specifies a pipe diameter of 1 inch, then when measured, it turns out that the result is not 25.4 mm. This is where the confusion of home craftsmen begins.

If we consider the technical characteristics of such a product, it turns out that its cross-section is equal to 33.249 mm. The fact is that with the designation of a pipe in inches, its outer diameter is meant, while the internal one corresponds to 22.4 mm.

Of course, this value is to some extent conditional, since the products have different wall thicknesses, respectively, the ratio of their diameters may be different. However, some uniformity in this matter still exists. Thus, if you convert pipe inches to centimeters, pipe 2 has an inner diameter of ~ 5 cm and an outer diameter of 6 cm.

However, it should be borne in mind when converting 2 inches to cm - the pipe in reality is unlikely to have a cross section of 66.4 cm. Moreover, for products made of different materials, the cross section in the metric system can be different due to the difference in thickness of their walls.

Therefore, in order not to get confused in the measurements, it is better to use the data from the GOST tables. Next we give the standard pipe diameter in inches and millimeters:

| Pipe diameters in inches (integer and fractional values) | Conditional pass, in mm | Section, in mm | ||

| Polymer tube | Steel suture | Steel seamless | ||

| one? | 25 | 32 | 33.5 | 32 |

| 1 1/4? | 32 | 40 | 42.3 | 42 |

| 1 1/2? | 40 | 50 | 48 | 45 |

| 2? | 50 | 63 | 60 | 57 |

| 2 1/2? | 65 | 75 | 75.5 | 76 |

| 3? | 80 | 90 | 88.5 | 89 |

Tip! If there is no reference literature at hand, the cross-section of the tubular product can be measured with a caliper and thus obtain a metric value.

Thus, a 1 inch pipe in centimeters can have a cross section of both 3.2 and 3.35. In large pipe products, the run may be even larger.

Of course, if the pipeline is mounted from identical parts, then no problems will arise. But, if the design is combined with parts made of different materials, for example, steel + plastic, then for their proper selection it is necessary to apply for information to the table. In the reference literature, you can find the diameters of various types of pipes.

Tip! For laying domestic domestic pipelines (water and gas pipelines), the most commonly used pipe is 1 1 - 4 inches, 2 ”and 3/4.

Inch thread

Often, speaking of pipe inch calculus, imply pipe (cylindrical) thread, which has a number of features, compared with the metric. It is usually cut into metal pipe products, as well as plastic fittings for pipes intended for collapsible type pipelines.

I must say that when installing pipelines in a threaded way (as a rule, a pipe of 1–2 inches - 6 ”), knowledge of the thread will also be useful.

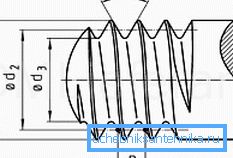

Its main characteristics are the following parameters:

- Step - the distance between the threads of cutting. Mandatory requirement for the step - consistency on the entire threaded section.

- Outside diameter - is the distance between the two upper opposite points, i.e. located on the crests of turns.

- Inner diameter - it differs from the outer one in that the distance is measured not from the upper, but from the lower points of the turns.

- Profile height - the difference between the outer and inner diameter.

Naturally, all these parameters are specified in inches, and not in millimeters. But this is not the only feature of this thread.

In addition, it differs from the metric by the following parameters:

- The shape of the crest of the coil. Inch cutting has a “sharp” profile as opposed to metric.

- The metric thread parameters are in millimeters.

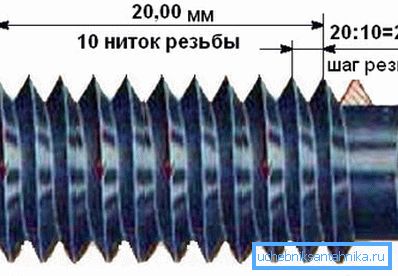

- The cylindrical cutting pitch is measured in threads, i.e. the number of turns (grooves) placed on a segment of 1 ”. In domestic pipelines used thread with such a pitch:

- 11 threads - corresponds to a metric step of 2.31 mm;

- 14 threads - corresponds to a metric step of 1.8 mm.

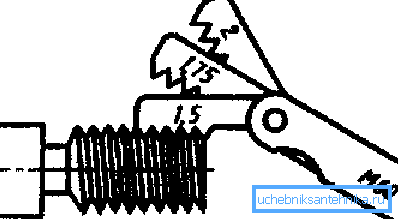

In some cases, when installing or repairing a pipeline, it may be necessary to measure thread parameters. Do it yourself is absolutely not difficult, the only thing you need is a special tool.

Note! Most often, the outer diameter of the cut is equal to the cross section of the pipe.

The outer diameter can be found using a caliper. To determine the pitch of the turns, a gauge is usually used - a tool in the form of a set of files.

Instructions for working with him are extremely simple:

- Files are attached to the thread.

- If the teeth of the plate coincide with the thread, you need to see what value is indicated on the plate, it will be a step of turns in millimeters. The price of such a tool is quite affordable, so every home master can afford it.

Here, perhaps, all the features of pipe diameter and pipe thread.

Conclusion

Inch is an inaccurate designation of the diameter of the pipe, as it may differ depending on the type of tubular product. Therefore, to obtain an accurate value, one should refer to the reference literature for information, or use measuring instruments.

From the video in this article, you can get more information on this topic.