Flexible connection for the mixer: how not to get confused

Flexible connection to the mixer - this is one of the most common elements used for the installation of plumbing fixtures. There are a huge number of different flexible hoses on the market, which makes the right choice of a suitable part difficult.

We want to help you understand the features and characteristics of the hoses, especially if you intend to mount the mixer with your own hands.

Flexible hoses for plumbing

Purpose

Flexible material liners are used to connect various plumbing fixtures to water pipes.

In general, the field of application of these products is much wider, they are found in almost any pipelines:

- gas,

- technical

- automobile, etc.

However, in our article, we consider only the plumbing segment of their use.

So, flexible supply is used to connect such devices:

- Faucets and mixers;

- Boilers;

- Shower cubicles;

- Washing machines;

- Dishwashers;

- Pumps and pumping stations;

- Geysers and boilers;

- Toilet bowls, bidet, toilet installations.

Why did this type of pipe become so widespread? Everything is very simple: using a flexible hose, you can connect any device without connecting steel or plastic pipes precisely to the junction, because for this you often have to not only cut and weld metal, but also shtrobit walls.

However, any inaccuracy will lead to the fact that the work will have to redo or move the device, which is very undesirable.

In addition, the mixer is often connected in a hard-to-reach area, especially for small bathrooms with a heap of pipes and various appliances. The use of a flexible supply removes any such problems, since it can be laid almost anywhere and along the most tortuous route.

At the stage of repair, it is enough for you to remove the water sockets from the wall or floor near the intended installation location of the washbasin. Then you simply select the liners that are suitable for the length and connect the mixer to the pipes.

Note! Hoses cannot be used as a replacement for the main and distribution pipes. It is also undesirable to use them in heating systems to connect radiators.

Device and materials

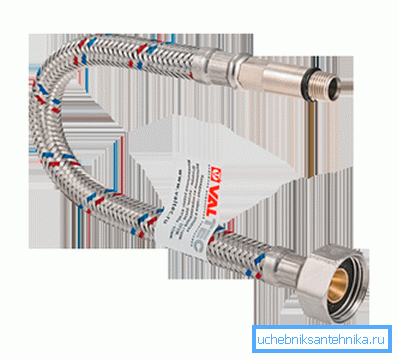

The flexible connection for the mixer is very simple - it is a rubber tube into which the fitting sleeves are inserted from both sides. From above, the connection of the pipe with the sleeve is pressurized with a steel crimp. Also, the product has an external reinforcement in the form of a braid of metal or polymer wire.

Female fittings (flare nuts) or male threaded unions are used as fittings.

- Most often, a nut fitting is used to connect the mixer (indicated by g / w).

- However, on sale you can find the option of a nut-nut (g / g).

- Sometimes choke-choke (w / w).

The most typical standard nut size is? inch fitting - M10.

Often there is a variant with a 1: 2 inch nipple, there is also a nut at 3: 8 inches (you need to use a transition fitting to connect it). Among plumbers, models with a long fitting are common and popular, since it is more convenient to connect them to the mixer at the bottom of the sink.

In high-quality models of hoses, fittings are made of sanitary brass (Cu Zn39 Pb3). It can be clean or nickel-plated. Crimping sleeve is made of stainless steel (GOST 08H18N10 or AISI 304).

Note! In modern hardware stores, there are often products with silicon-aluminum alloy fittings (silumin). This is an unacceptable option that can collapse even at the installation stage, so you should not buy it.

It is easy to determine what the nut and fitting consists of: if you scratch the nickel-plated brass, the bottom of the groove will be yellow. Silumin will remain monotonous. In addition, aluminum alloy is much lighter than brass.

The hose itself must consist of ethyl propylene rubber (EPDM), a non-toxic rubber approved for transporting drinking water. This material is elastic and able to withstand peak pressures up to 50 atmospheres.

Here, when choosing, it is necessary to smell the product: if the characteristic unpleasant smell of synthetics emanates from it, then the hose is made of technical toxic rubber, which, moreover, breaks easily and crumbles during strong bending.

The union nut must be completed with a sealing gasket, and the union with one or several rings. These gaskets and rings must also consist of ethyl propylene rubber.

The outer braid in normal products consists of stainless steel or polymer fiber. Such connections serve from 8 to 20 years and withstand a working pressure of 10-20 atmospheres.

However, there are models with aluminum sheeting on sale, and sometimes the reinforcement consists of ordinary galvanized steel.

Note! Aluminum braid will last a maximum of 2 - 3 years, steel can rot in a week. As a result, the hose can burst, and petty savings on the quality of the liner will give you a lot of serious problems.

The length of the liner usually ranges from 30 to 200 cm, however, if desired, you can find almost any size. Also, flexible connections sometimes include bellows - tubes made of corrugated stainless steel. They are more durable and reliable, however, and their price is higher.

Note! There are stripes on the sheath. Blue - for cold water, red - for hot, blue with red - for universal, yellow - for gas. Substandard products may not have a similar label.

Installation rules

Despite the fact that the instructions for installation of products is incredibly simple, when you connect them you should follow certain rules:

- Before connecting, be sure to inspect the product for defects, braid breaks, the presence of gaskets and rings;

- When choosing a hose, select a length so that it is not stretched., and the turning radius was not less than 5 - 6 of its outer diameters;

- No kinks during installation, instead it’s better to make rings;

- It is strictly forbidden to twist the tube along the longitudinal axis;

- Threaded connection of the nut and fitting does not need to be sealed with tow or FUM tape, its role is played by rubber rings and gaskets;

- Screw the nut by hand until it stops, then pull the key to half a turn, a maximum of 270 degrees. Padding fraught with cutting gaskets, which leads to leakage.

Note! Purchase only high-quality products made from standards-compliant materials. Savings can cost too much.

Conclusion

The use of flexible connections allows you to connect to the plumbing a variety of plumbing fixtures. When installing mixers, they are often completely irreplaceable, so the choice of a suitable model should be taken seriously, as the video in this article will help you.