Mixing unit as a mandatory part of an efficient heating

In our time, the issue of efficiency of heating communications is paid the most attention. In addition to the mandatory elements: the boiler, pipelines and radiators in the design increasingly include special units designed to improve circulation and temperature control. To install a pumping and mixing unit with your own hands can do almost any person, the main thing is to follow a few important recommendations.

The main advantages of using the considered structures

If you doubt the feasibility of installing a mixing-pumping unit, then you should familiarize yourself with its main advantages:

| Convenience management | The mixing unit greatly simplifies the process of adjusting the temperature of the coolant. In this setting can be made either manually through a special valve, or in automatic mode, using an electric drive and a device for measuring the temperature in the room. That is, the system can be completely autonomous and operate without outside intervention. |

| Efficiency | Experts confirm that the installation of the node in question reduces the energy consumption for heating by 30-50%. Communications work as efficiently as possible due to the fact that a certain temperature is maintained and a constant circulation of the coolant is ensured, which contributes to the best heat transfer |

| Durability | The service life of the regulatory system is quite impressive and can be over 50 years. Do not be afraid of the price of the product, because it is enough to spend money once to ensure savings and convenience for many years to come. The main thing is to select better options, rather than budget segment products. |

| Easy installation | The installation instructions are simple and clear, so even those who have no experience in this field will cope with the work. This allows you to save significant funds, which is also important in a situation where there are budget constraints. |

Tip! It is still better to select a specific modification with the involvement of a specialist, since it is necessary to take into account a number of factors, and without due experience one can miss an important point.

Modifications of nodes and features of their use and installation

It is worth noting that the market is represented by a very diverse equipment that is designed for different systems with their own specifics of operation, we consider the most important factors, which in no case should not be forgotten.

Types of equipment

The design of the system depends largely on what valve it uses; it is for this feature that two main types are distinguished - versions with three-way and two-way units.

The water mixing unit with a three-way valve has the following features:

- High throughput, allowing you to choose the best option even for the largest structures. By and large, this option is the only possible one, if we are talking about large systems with huge volumes of circulation.

- Mixing takes place as follows: hot water flows from one nozzle and a cold return flows to the other. Everything is pretty simple and reliable, which is why this option can be recommended for a wide range of applications.

The use of two-way valves has the following features:

- This option is suitable for small rooms due to low bandwidth. The design is quite simple, which ensures its durability, and does not require maintenance.

- Mixing the coolant is performed continuously, which eliminates the possibility of overheating of the system and provides a smooth temperature control.

Application options

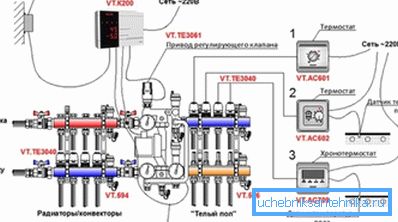

The constructions of the group in question can be used in a wide variety of systems. Consider the more common ones:

- Designs of this type are most in demand in floor heating systems.. This is due to the fact that for such communications it is very important to maintain a constant temperature regime, and any drops will negatively affect the state of the system. In trade, you can choose ready-made designs for any system parameters, the main thing is to make a competent project that takes into account all the features of communications.

- Mixing unit for solid fuel boiler makes the system more stable and uniform, especially when fully loaded equipment. Its use allows you to increase the life of the equipment and provides significant fuel savings due to the fact that prevents excessive heating of the coolant. In addition, the minimum temperature is monitored, thus avoiding condensation.

- The mixing unit for the water heater is used in air-conditioning and ventilation systems to control the temperature of the liquid in the heat exchanger and, as a result, the temperature change of the airflow passing through the structure. Due to the complexity of the calculation in air conditioning systems, it is better to purchase ready-made blocks, which are most often reflected in the design documentation.

Installation Recommendations

Despite the seeming complexity of the design, it is very simple to install it into the heating system, the main thing is to observe the correct sequence of actions and to do all the operations carefully.

In general, the workflow is as follows:

- First of all, it is necessary to prepare all the required: tools, equipment itself, sealing compounds for joints, etc.

- Then, at the location of the structure (and it must stand before entering the contour of a heated floor) a collector cabinet is assembled or assembled on its own, its dimensions and configuration depend on the features and dimensions of the equipment used.

- Next, the node is fixed to the surface so as to ensure its immobility, and it would be possible to easily reach each element if necessary.

- First of all, the kneading system is connected, it goes from the return line to the standpipe, and all the required sensors are installed. They can be purchased separately, but it is better that they were originally provided for in your chosen configuration.

Note! The quality and accuracy of the connection of the measuring equipment should be given the closest attention. The security of the system and the accuracy of its settings during operation largely depend on this.

- Further join the other pipes, this type of work is no different from other mates, the main thing - careful sealing of threaded connections.

- The final stage is a test run of the system in order to check it for tightness and carry out the initial settings. If everything functions normally, then the work can be considered completed.

Conclusion

Properly selected, well-established and tuned mixing unit allows you to optimize the operation of the heating system and reduce heating costs. The video in this article will tell you more about some important points of the workflow.