Mixing valve: device, principle of operation, application

3-way mixing valve is a common type of shut-off and control valves used in hydraulic and pneumatic systems for solving a number of problems. In heating and hot water systems, this type of fittings is indispensable and is used quite widely. We will tell about the design and purpose of the mixing valve.

Three-way valve

Purpose

Mixing valves are used quite widely, because they allow you to solve many problems, and in most of them there is no alternative to this type of valve. The device has the form of a common tee, that is, it has two inputs and one output.

If we send water streams with different temperatures (cold and hot) to the inlets, then we will be able to get the following options at the outlet:

- Cold water flows freely from inlet (A) to outlet (AB), hot water does not enter the outlet;

- Cold and hot water arrive at the outlet (AB) at the same time, while their flows are mixed, and the water has an average temperature;

- Cold water is blocked and only high temperature (B) flows into the outlet (AB).

Sometimes there is also a fourth position - when both channels are closed and no water enters the exit. In this case, the device is more correctly called the four-way valve.

If we connect the feed to the output, then we get the following results:

- The stream moves from the output (AB) to the input (A), and does not enter the input (B);

- From the outlet pipe (AV) water flows into the inlet (B), and does not enter the inlet (A);

- The stream is divided into both channels.

Note! We see that the device is capable of mixing two streams, opening the flow of one channel and locking the flow of the other, dividing the flow into different channels and turning the flow into another channel.

These features are widely used. In hot water supply and heating systems, mixing valves are installed, in most cases, for the home of cold water or water from the return pipe to the hot coolant in order to achieve the required flow temperature.

For example, a floor heating system. It is known that for the contours of a heated floor the temperature of the heat carrier must be within 40 - 50? С; however, the boiler produces the heat carrier heated to 90 - 95? С.

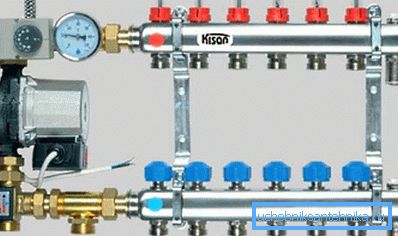

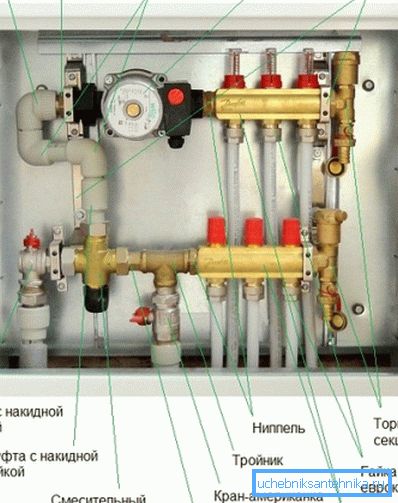

To solve the problem, a mixing unit is installed in front of the underfloor heating collector, where the three-way valve is used to get the temperature of the liquid from the return to the supply, thereby reaching the desired temperature.

Three-way valves are also used in mixers with electronic or thermostatic control, in ventilation systems, in various components of automotive equipment and hydraulic systems of a wide purpose.

Of course, these units found the widest application in the transport and service pipelines.

Device and principle of operation

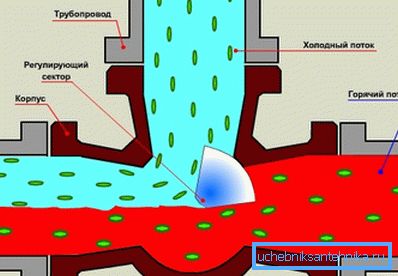

To better understand the operation of the mixing valve, one should consider its device.

If you do not go into all the details, the product has the following structure:

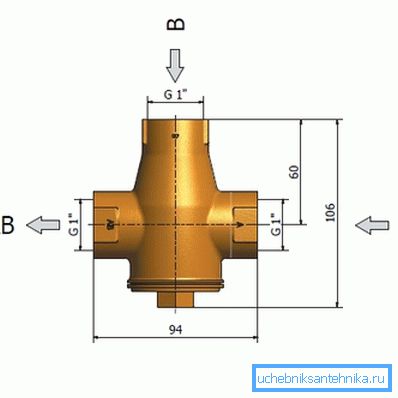

- Brass body in the form of a tee and the fourth exit, closed by an adjusting nozzle;

- In the adjusting socket is installed the locking and adjusting mechanism, which is a cone in the form of a cone, a ball or a sector, as well as a spindle connected to the stopper, which allows the mixer valve to be turned or shifted;

- Cork saddle with special seals made of synthetic rubber, plastic or PTFE;

- Manual adjustment knob, thermostatic nozzle or servo.

For hot water and heating systems, valves with a rod or cone adjustment system are most often used. The stem is connected to the conical plug, and when it moves up and down, the flow is adjusted.

As a rule, to control such a mixer, a thermostatic head is used, the actuator of which reacts to the expansion of a special liquid that responds to changes in the measured temperature.

The temperature sensor can be installed inside the device, or it can be moved to a remote point of the system. Most often the thermal head is adjusted within 30 - 60? С.

In more advanced automatic control systems or smart home systems, the mixing units can be controlled by controllers. Then the valve stem regulates the servo, which receives commands from the controller. This achieves the most subtle and precise control.

In general, it must be said that in modern heating and hot water systems, it is thermostatic mixing units that have received the greatest popularity, since they allow to obtain water at a given temperature without human intervention.

At the same time, there is a fairly high stability and reliability of the device, which is very important when used in systems whose price exceeds the semi-annual salary.

Note! Most modern models have such a design that allows you to connect to the product a variety of heads - thermostatic, with a remote sensor, servos and manual adjustment knobs.

Installation

If you are planning to install the valve yourself, then a little instruction will be useful to you.

In fact, there is nothing difficult to install, especially as it concerns modern models for hot water supply and heating systems, but still.

- First, we must immediately take into account that for normal operation and maintenance of the device should be easily removed. To do this, ball valves are installed on both sides, and the connections must have captive nuts or American adapters.

- Secondly, it is better to provide the product with coarse water filters, then its locking and regulating mechanism will last longer.

Thermostats with a remote sensor, which is installed on the collector supply of coolant to the contours of the floor, are usually used in the mixing nodes of warm floors. This allows you to more accurately adjust the temperature and increases the reliability of the system.

For installation on hot water supply, especially on valves with electronic control, a circuit with a servo drive and a controller is used. This allows you to quickly adjust the temperature of the water and quickly respond to changes in it.

Also in the DHW use models with manual control to switch the flow in different channels. In this case, it’s not a mixing valve, but a separation valve.

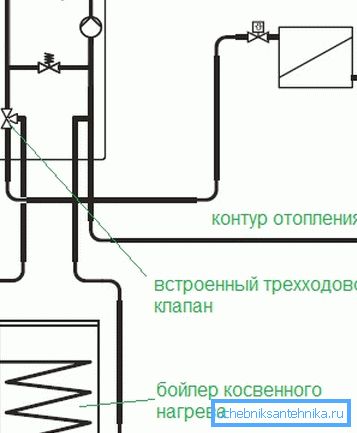

For tying boilers and heaters, as well as indirect heating systems use models similar to those used in pump-mixing modules of warm floors.

Often, devices are already installed in the factory configuration of double-circuit boilers for water heating, which allows to obtain a separate coolant and separately hot water.

Conclusion

A valve for mixing water flows at different temperatures is an indispensable component of many hydraulic systems, including heating and hot water systems. Knowledge of the principle of its work and the features of the application will help you better understand the structure of any plumbing scheme.

The video in this article allows you to visualize the work of the product.