Concrete rings for sewage: the selection and use of

Reinforced concrete sewer wells are practical and quite acceptable performance characteristics. They are simply assembled from typical elements, and it is thanks to this simplicity that these designs have gained such significant popularity.

In our article we will describe how rings are manufactured and labeled for the arrangement of these wells, and we will also describe in detail the method of their installation with our own hands.

Prefabricated items

Characteristics and features of production

Concrete goods rings for sewerage are piece products from which make inspection and inspection wells, providing access to pipelines laid underground. Also, septic tanks, wells for water supply and other structures are sometimes assembled from ring elements (see also the article Plastic sewer manholes: types and scope).

The method of manufacturing these parts is practically no different from the technology of casting other concrete blocks:

- According to the requirements of GOST, concrete of grade not lower than B25 is used as the main raw material. Frost resistance of the product should be 100 cycles or more, and moisture permeability is taken at the level of class W4.

- Steel reinforcement is introduced into the concrete to impart rigidity to the part. In the reinforcement it is allowed to use hot-rolled steels of class from A-І to A-ІІІ, as well as special grades At-IIIC or At-IVC.

The production process is as follows:

- The formwork is set reinforcing frame.

- The formwork is filled with concrete.

- The material is subjected to vibratory compaction, which contributes to improving the mechanical strength and water resistance of the part.

- Then the primary drying of the product takes place, after which the stripping is performed.

- In the future, the rings can be subjected to autoclave treatment with hot steam, which ensures the acceleration of curing.

Note! As in the case of other reinforced concrete products, the price of autoclave rings is higher, but they are characterized by a long service life and a safety margin.

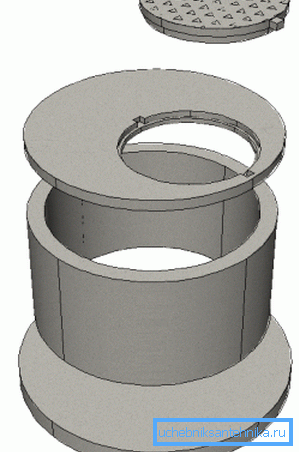

In addition to the rings, other parts of sewage wells are also made using this technology - bottoms, locks, covers, additional elements, etc.

Marking and main sizes

If you need a sewer well from precast concrete, then first of all you should choose the appropriate size of the ring. To facilitate this task, it is worth understanding the marking of such parts.

According to the standards adopted by us (GOST 23009 and related documents), each ring is marked with a code of several groups of letters and numbers:

- First, an alphabetic index indicating the type of product is put, and the size of the internal diameter in decimeters is also indicated. For example, KC10 is a “wall ring with a diameter of 1 meter.”

- This is followed by a digital index indicating the height (also in decimeters).

- The third group of characters is used for special marks. For example, the designation "P" indicates that the production used concrete of low permeability.

In addition, the marking can be used such marking parts of the well:

- Wall ring - COP.

- Support ring - KO.

- Extra ring - CD.

- Bottom or bottom plate - Mon.

- Base plate - software, etc.

Below we provide a table in which the dimensions and mass of the most “running” parts are listed, from which the G & B sewer wells are assembled:

| Marking | Dimensions, mm | Weight, kg | ||

| Diameter | Height | Wall thickness | ||

| KC10-3 | 1000 | 300 | 80 | 200 |

| KC10-5 | 1000 | 500 | 80 | 330 |

| KC10-6 | 1000 | 600 | 80 | 400 |

| KC10-9 | 1000 | 900 | 80 | 600 |

| KC7-3 | 700 | 300 | 80 | 130 |

| KC7-10 | 700 | 1000 | 80 | 440 |

| KC20-6 | 2000 | 600 | 100 | 1000 |

| KO - 6 | 580 | 70 | 120 | 50 |

Note! The complete nomenclature is very extensive and allows you to pick up items for almost any size and configuration of the well.

Self-assembly process

If you decide to make concrete parts (new or used ones - they can also be used) a septic tank, cesspool or manhole, then it is worth exploring the installation work. At first glance, there are no special tricks here, but a newbie should pay attention to a number of unobvious moments.

So, the instruction for the construction of sewer structures on the basis of prefabricated rings would be:

- To begin with, we calculate the volume of capacity we need, after which we determine the number and dimensions of suitable parts.. As a rule, products of this type are used entirely, without undercutting (too troublesome), therefore, for an accurate “size” hit, additional finishing rings of a small height are purchased.

- Then you need to decide whether we will dig the excavation by hand with a trench tool, or rent an excavator.. In the second case, the costs will increase by an order of magnitude, but the work will be done much faster.

- If we decided that we can handle it with shovels, then first we dig a pit to the depth of one ring. We install the part into the pit, and then gradually we begin to deepen it, lowering the edges due to the excavated soil.

Tip! It is better to move the rings with the help of a truck crane, since even two or three of us will be able to cope with such a mass. And if you try to roll - there is a risk that the part will crack.

- We continue to work, increasing the wall by installing new rings. After reaching the desired depth, carefully level the bottom, which is then filled with a layer of gravel and sealed with clay or concrete.

- We get all the necessary pipes into the well, making holes in the walls using a perforator or a drill with a diamond nozzle.

The next very important stage is to ensure the water resistance of the entire structure.

For this:

- In the gap between the walls of the pit and concrete rings fall asleep clay-sand mixture. If the size of the gap allows, you can also treat the walls with mastic based on bitumen.

- Inside, we carefully seal the seams between parts with sealant. This protective circuit will have to be updated from time to time.

- Next, we cover our well with a slab with a hole for installing a manhole. We install the ventilation pipe, if the design provides for this.

Conclusion

RC ring for sewage is very convenient to use. Despite the considerable weight, they allow you to quickly assemble the casing of wells and septic tanks, while the cost of the design is quite acceptable.

If you are interested in these elements, we recommend that you study them in more detail by viewing the video in this article.