How to choose a compressor for a septic tank

Septic tanks installed in private estates and cottages, play an important role in the comfort of living person. On sale there are a huge number of models of septic tanks, both domestic and imported. Each homeowner can choose a suitable model for himself, and install it on his country site. But do not think that just installing a septic tank, the system will work fine. The fact is that for the complete decomposition of waste, it is necessary to complete the septic tank with additional equipment. One of these additions is the compressor. To understand this device, let's consider its need, principle of operation, installation, and how to choose a compressor for a septic tank installed on your site.

Purpose of the compressor

For a complete understanding of the purpose of the compressor, let's briefly review the operation of the septic tank. The operation of the device is to perform the collection and recycling of sewage. The equipment includes:

- capacity;

- pipe system;

- set of pumps and compressor.

Pumps carry out pumping of liquid waste in the system, and one cannot do without it, and on the compressor some people save. And this is wrong. Thanks to the compressor, air is supplied to the septic tank. When interacting with air, the activity of bacteria that are involved in the decomposition of sewage increases.

Types of devices

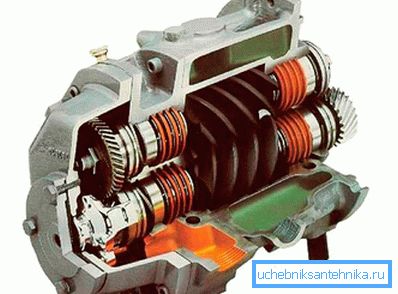

Compressors for septic tanks are of two types: screw and membrane.

- Screw compressors have two rotors. Rotating, they trap air and inject it into the container. Because of its compactness, such models are installed in septic tanks with a small capacity. They are very economical and almost silent in operation.

- Membrane compressors are widely popular for septic tanks installed in cottages. Their feature is simple operation and ease of maintenance. The work of this model consists in the coordinated work of the membrane and valves, thereby creating pressure in the chamber. Directly from the chamber, oxygen enters the septic tank.

Tip! Installation of reciprocating compressors in septic tanks is not practiced because of their high noise level.

Design features

All types of compressors for septic tanks are powered by electricity and are designed to force air into the tank with sewage. Based on the fact that the capacity of septic tanks are different in volume, therefore, the compressor must be suitable for power, to supply the required amount of air. For large capacity septic tanks, several compressors are installed. This allows for a more complete wastewater treatment. Basically, the compressor is mounted in a septic tank not by itself, but together with pumping equipment, ensuring its proper operation.

Installation of the compressor

If you study the manufacturer's instructions, the installation of the compressor will not cause unnecessary questions. Installation is easy, and almost any person will be able to carry it out independently:

- Over capacity of a septic tank the compressor, ready to work, is established.

- The outlet connection is connected to the aerator.

- The power supply is connected to the compressor and the device is ready for operation.

Connection question solved!

Device selection tips

To perform the complete processing of sewage, they must be settled and fermented in an airtight container, and air is not required for this process. But for aerobic decomposition, not to do without air supply. For this purpose, you can install a biological treatment station, which is quite an expensive pleasure.

Not every device model can fit your septic tank model. When purchasing a compressor, it is necessary to pay attention to some parameters:

- Do not buy a cheap device. This will quickly affect the quality of work, and maybe even fail. It is better to buy a compressor of a company that has proven itself in the market for its quality and reliability.

- All compressor parts must be corrosion resistant.

- Branded compressors, as a rule, have a long service life.

- Silent operation of the device. No one will like the constant noise of a running compressor at the dacha.

- Compressor power must match your system model. A mismatch of compressor power can lead to a mismatch in the amount of oxygen supplied to the septic tank. Such an imbalance will affect the vital activity of microorganisms inhabited in the septic tank, which entails a deterioration in the quality of recycling of sewage.

Demanded device models

Everyone knows that the highest quality equipment is produced in Japan. Therefore, the compressors of Japanese manufacturers are in great demand. They are protected by a waterproof casing, they are almost inaudible in their work and they do not consume much electricity. And their reliability in work will never let you down. In a specialized store, you can always choose a model worthy of price and quality.

Video

The author of this video shares his observations on the reliability of compressors used in the septic tank.

Topas: